RFID in Manufacturing: How Does It Actually Work on the Factory Floor?

77RFID in manufacturing is reshaping shop floors, from asset tracking to real-time production visibility. See how factories use RFID to cut errors and gain control.

MoreAll RFID Product

In April 2025, USDA released the latest Animal Disease Traceability (ADT) regulations. Dairy cattle and certain beef cattle transported across state lines must wear electronic ear tags compliant with the 840 standard.

Honestly, the regulations themselves are dry, but in practice at the ranch, things often don’t go perfectly: sometimes you might scan a cow three times before it reads successfully, making you wonder whether it’s your technique or the chip itself acting up.

The design goal of electronic ear tags is clear: durable, waterproof, UV-resistant, tear-resistant. But in real-world operation, you’ll notice tags may fail to read a few times under strong sun or heavy rain—experienced ranchers consider this normal.

The benefits are obvious: electronic ear tags combined with handheld RFID readers allow real-time tracking of cattle health, reproduction data, and feed consumption. However, this system demands reliable batteries, data synchronization, and network stability—signal dead zones on a ranch can be more stubborn than the cows themselves.

With USDA new rules in effect, RFID is becoming standard ranch practice. We often talk about “HDX vs FDX-B trade-offs,” referring to different chip protocols’ balance between reading distance, interference, and cost.

A dairy ranch in central California tested 1,200 cows: the average tag reading success rate was about 95%. The remaining 5% were either broken tags or ears too muddy or wet to scan. This “imperfect state” more realistically reflects ranch operational challenges.

Choose the right standard: Always follow USDA 840 standards. Don’t cut corners with cheaper tags, or you risk fines or rejected shipments for interstate transport.

Environmental suitability: California sun, Texas dust storms, Colorado wet snow—select tags with proper weather resistance.

Supporting equipment: Handheld readers, mobile apps, and backend management systems must be compatible. Cheap systems are prone to data loss, breaking the traceability chain.

Training operators: New ranch hands scan slowly or use inconsistent techniques. Hands-on training simulating real scenarios is essential.

Maintenance and inspection: Check tags and readers during daily rounds. Using red or blue tags for marking can help identify problem cattle quickly.

At a dairy ranch in Fresno County, California, the owner manages about 800 cows using an electronic ear tag system. Scanning occurs twice daily, taking roughly 90 minutes each time. Occasionally, battery depletion or cow resistance causes failures.

Experience Summary: “Cows won’t automatically cooperate just because you bought new tags, and equipment isn’t always reliable. But you can optimize workflows and leverage operational experience to keep failure rates acceptable.”

The USDA new rules bring pressure but also drive ranch modernization. Electronic ear tags aren’t perfect—real-world challenges include occasional chip reading failures, device power loss, and weather interference. These are the real “traps.”

However, understanding workflows, environments, and data synchronization enables compliance while improving management efficiency. Future cattle management won’t rely solely on technology, but RFID can help you avoid unnecessary mistakes—success largely depends on experience and execution, not just the tags themselves.

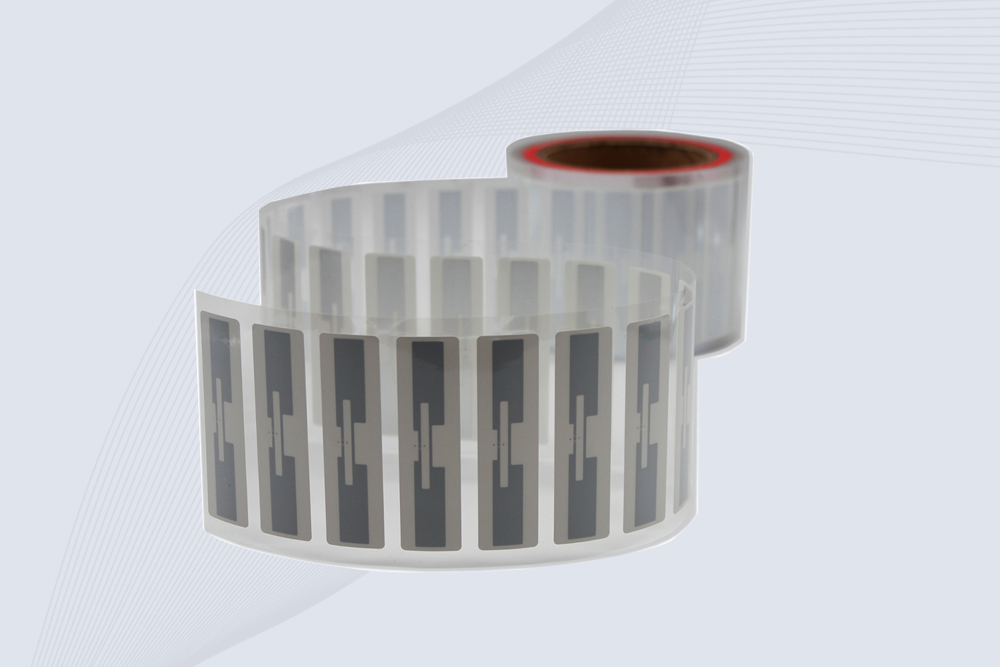

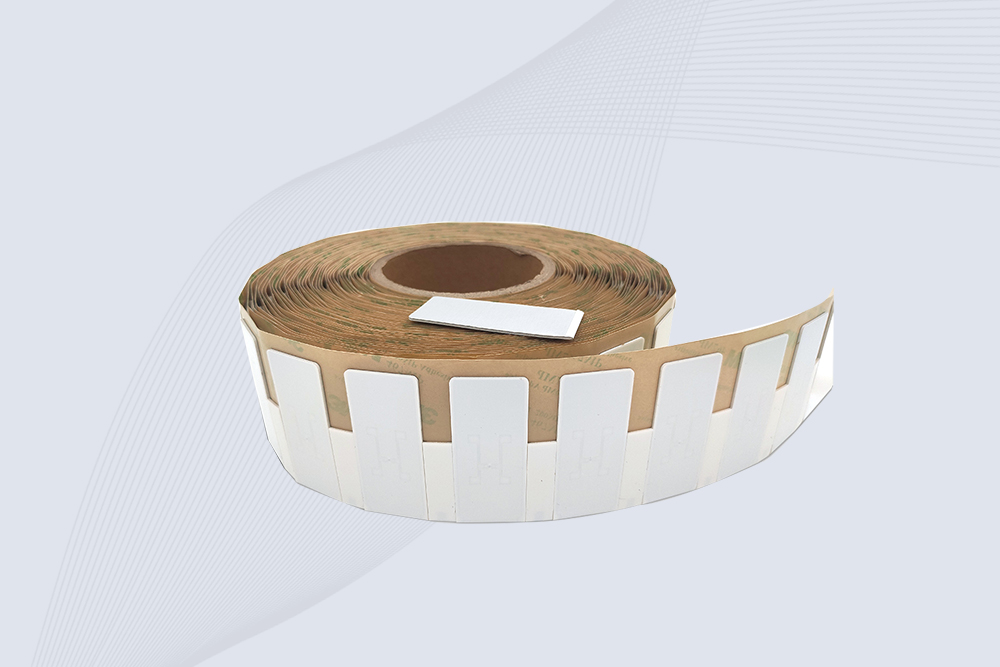

CYKEO Passive RFID Tags are made for wet and high-humidity environments where standard labels do not last. This rfid passive tag is often used around liquids, chemicals and temperature changes, providing stable reading distance and long data life for industrial tracking.

CYKEO CK-BQ1504 Metal RFID Tags is a compact anti-metal UHF RFID solution built for direct mounting on metal surfaces. With stable 8-meter read range, Ucode-8 chip, and long data retention, this rfid metal tag fits tools, containers, automotive parts, and industrial asset tracking.

CYKEO CK-BQ7020 On-Metal RFID Tags are designed for reliable tracking on steel and metal surfaces. Built with an FR4 epoxy body and industrial-grade chips, these On-Metal RFID Tags deliver stable performance, long data life, and chemical resistance, making them a dependable RFID anti-metal tag for harsh environments.

The CYKEO CK-BQ6025 Anti-Metal RFID Tag is built for metal surfaces where standard tags fail. Designed for long-range performance, harsh environments, and stable data retention, this Anti-Metal RFID Tag is ideal for industrial assets, containers, and equipment tracking using on metal RFID tags.

RFID in manufacturing is reshaping shop floors, from asset tracking to real-time production visibility. See how factories use RFID to cut errors and gain control.

MoreThis article provides a comprehensive overview of rfid reader portable (handheld RFID readers), covering core functions, working principles, typical application scenarios, and key selection criteria, helping enterprises achieve more efficient tag ...

MoreSomeone asked me can rfid be read through metal after their warehouse rollout failed. Here's what I learned testing CYKEO gear on steel racks and oil drums.

MoreUnderstand the differences between NFC and HF RFID technology, including range, applications, and compatibility. Learn how Cykeo’s solutions optimize both for secure data exchange.

More