Submit your request to us

We will contact you as soon as possible.

All RFID Product

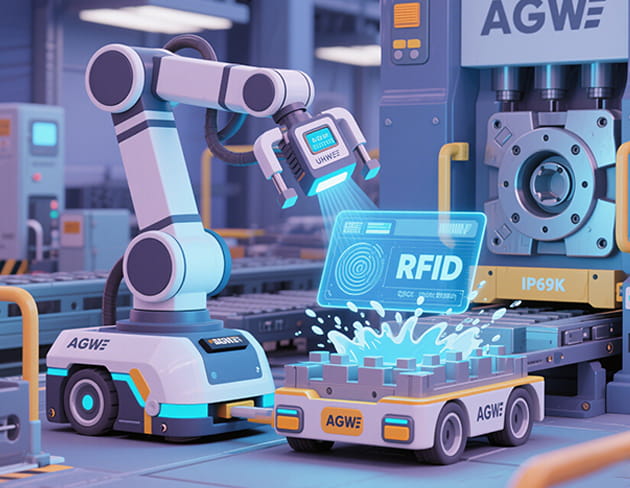

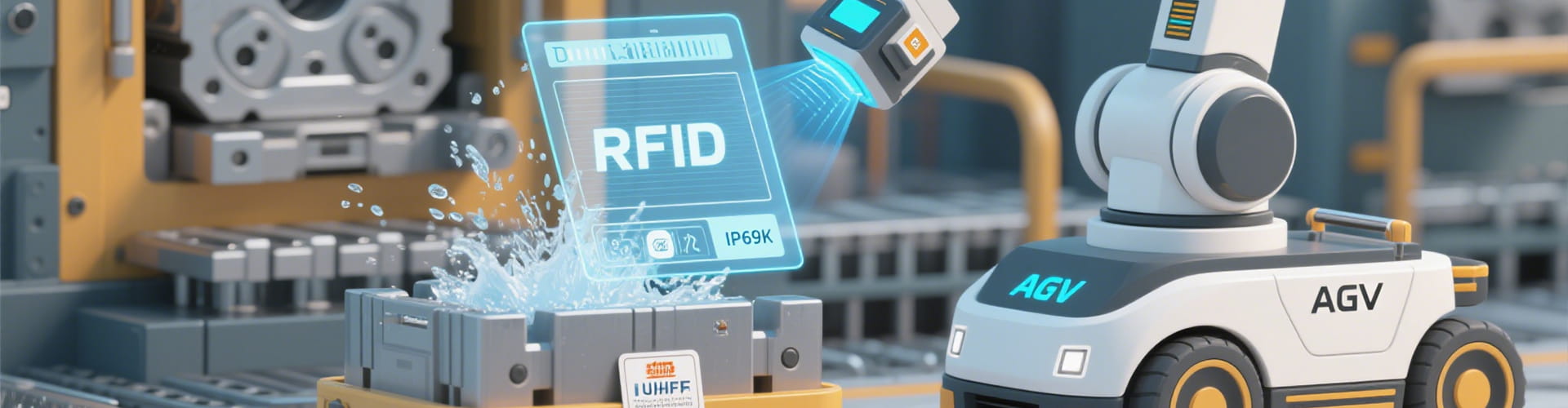

RFID Solutions for Smart Manufacturing

RFID Solutions for Smart Manufacturing

Traditional production lines face bottlenecks from manual inventory checks, misplaced components, and delayed quality inspections. Our industrial RFID solutions for smart manufacturing deploy UHF RFID tags and IoT-enabled sensors to create a connected, data-driven production ecosystem. By embedding IP69K-rated RFID tags into raw materials, work-in-progress (WIP) items, and finished goods, manufacturers gain real-time visibility across the entire value chain – from supplier deliveries to final packaging.

The system’s touchless scanning eliminates manual data entry: overhead RFID antennas track 1,200+ items per minute with 99.99% accuracy, while AGV-mounted readers update component locations during autonomous transport. Integration with MES/ERP systems (SAP ME, Plex Systems) synchronizes production data, enabling AI-powered dashboards to optimize cycle times, predict machine downtime, and reduce scrap rates by up to 45%.

Key Components:

1 Eliminate Production Errors

Replace paper-based work orders with automated RFID-guided assembly (zero manual scanning).

2 Accelerate Throughput

Track 800+ WIP items/hour via RFID-enabled conveyor belts – 15x faster than barcode systems.

3 Optimize Maintenance

Reduce unplanned equipment downtime by 70% through RFID-triggered predictive servicing.

| Metric | RFID System | Barcodes |

| Line Stoppage Time | 0.2 sec/scan | 6 sec/scan |

| Defect Detection Rate | 99.6% | 82% |

| WIP Tracking Accuracy | ±0.1% | ±8% |

Our RFID kanban systems automate JIT workflows through:

Our hygienic RFID solutions meet strict sanitation standards:

Our OPC UA gateways enable seamless interoperability: