Cykeo RFID Tags

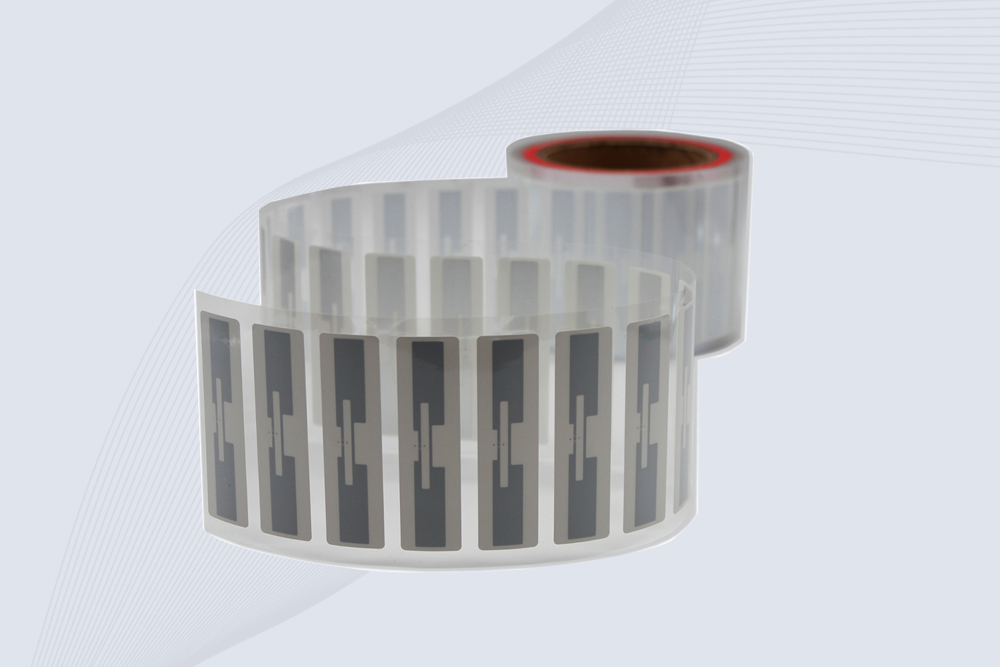

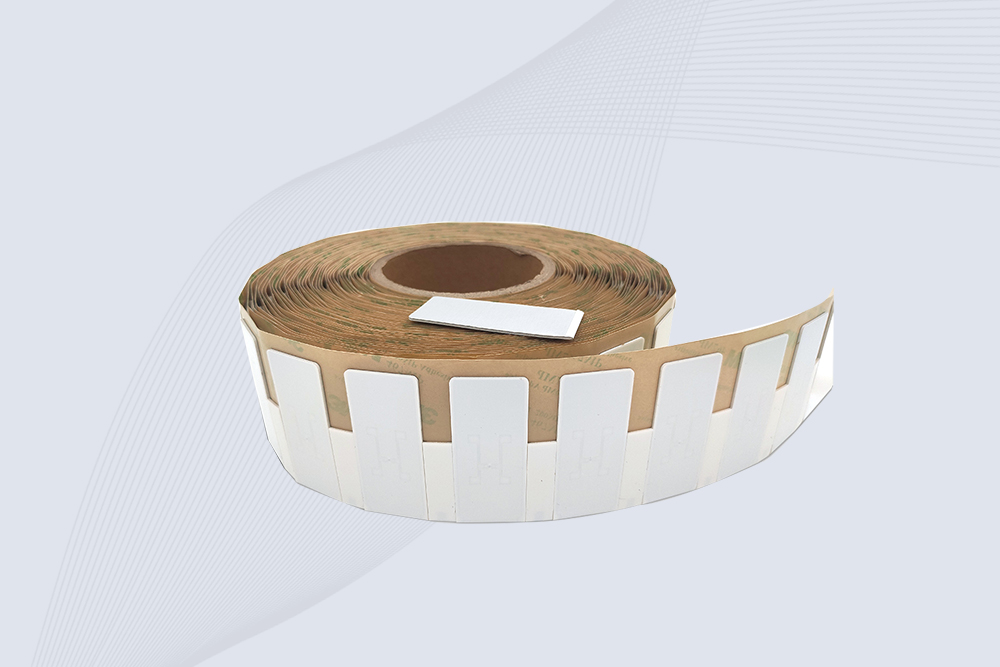

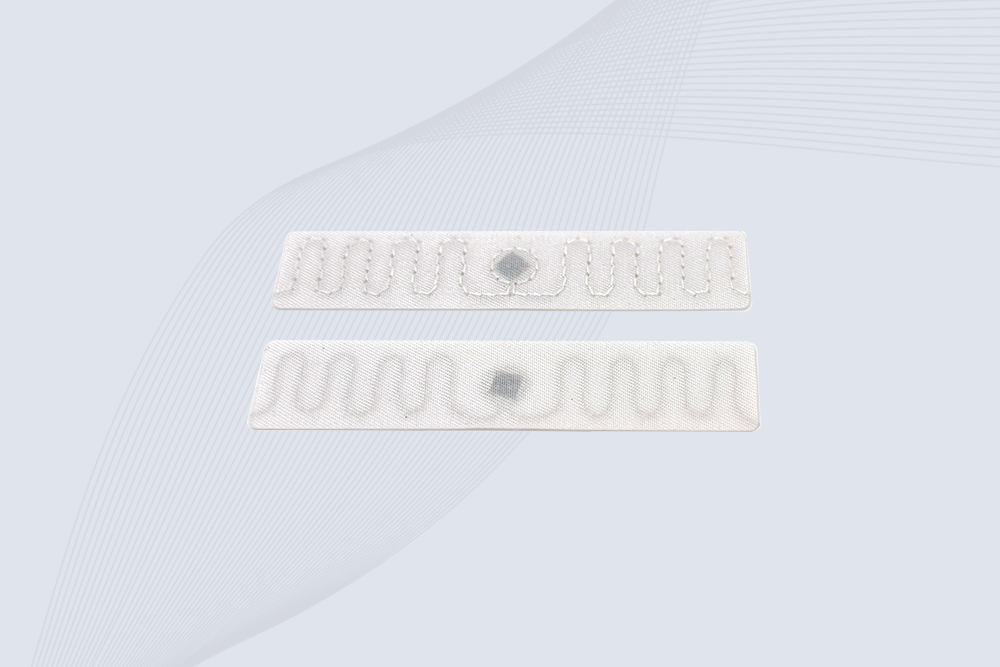

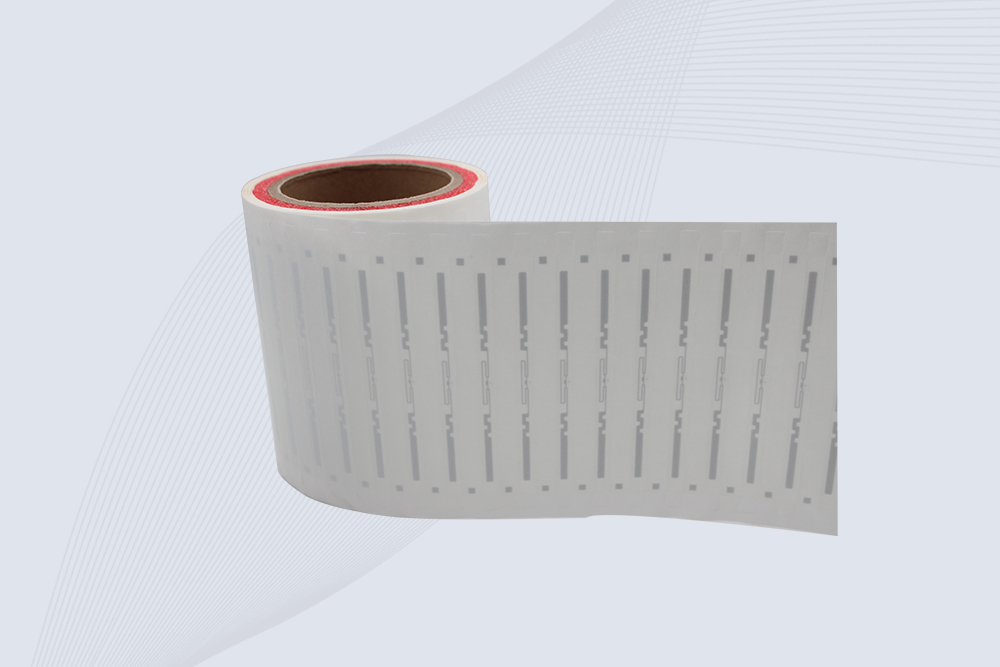

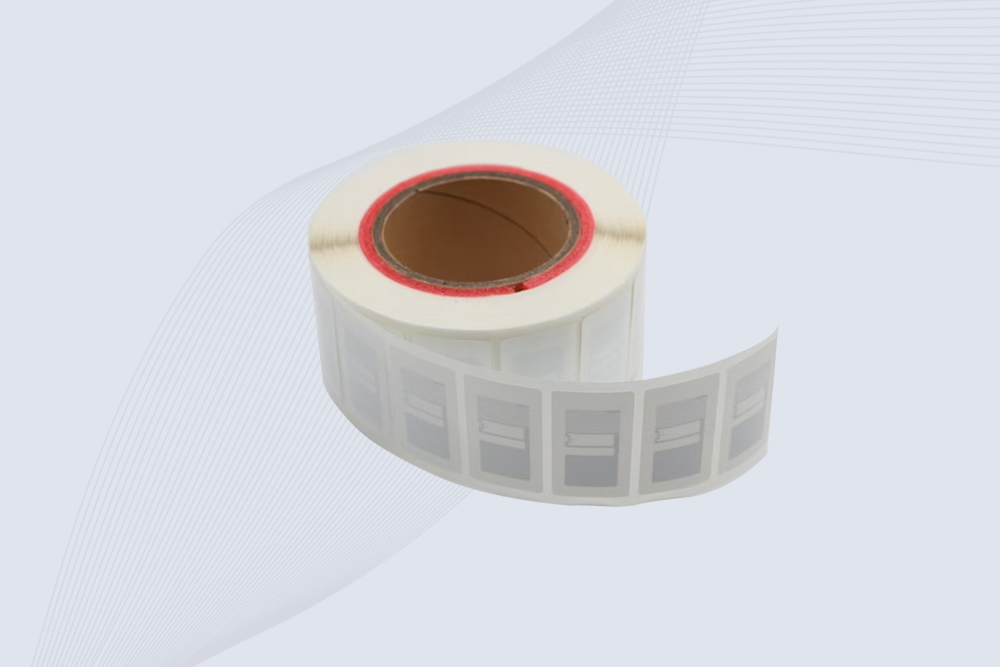

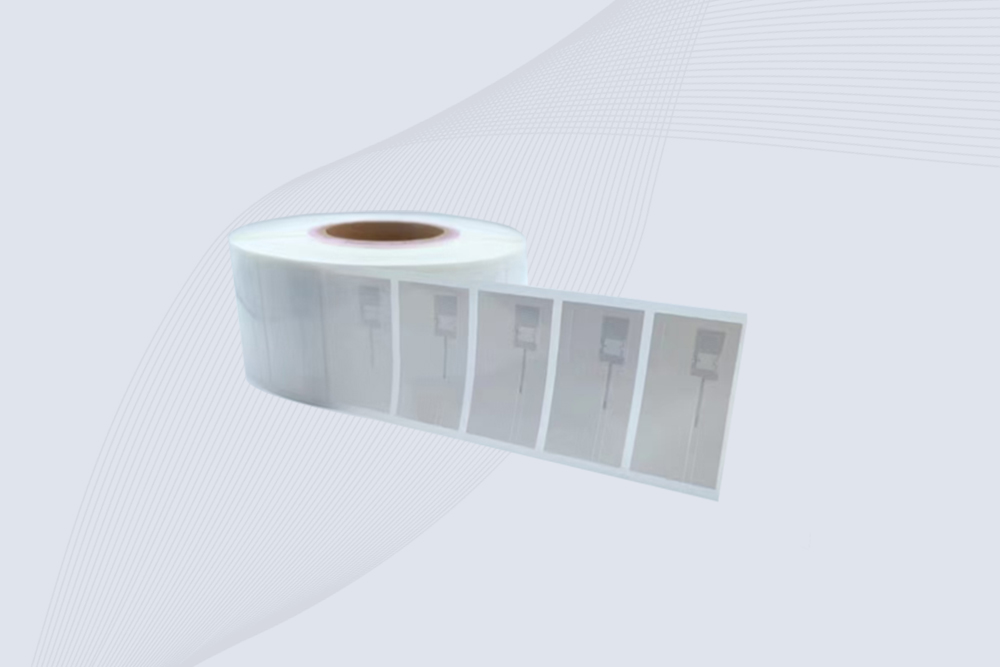

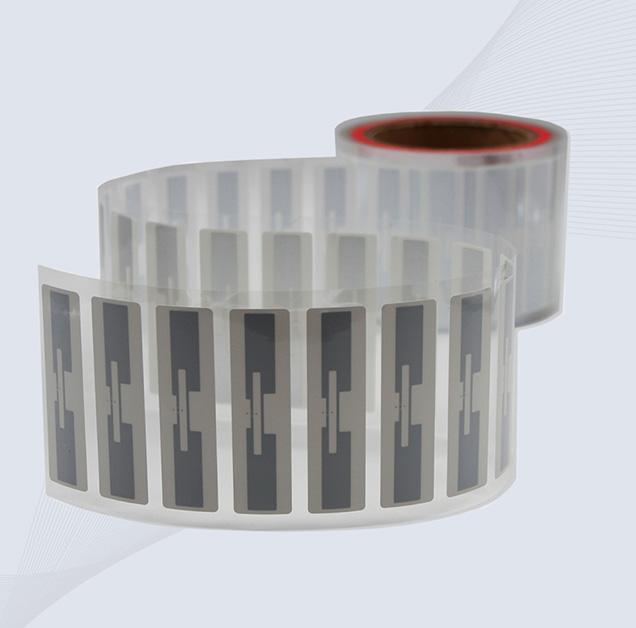

Cykeo supplies RFID tags that are mainly used together with standard HF and UHF RFID readers. The current range includes HF RFID tags, UHF RFID tags, HF RFID cards and UHF RFID cards. These products are usually selected as part of a complete RFID system rather than used on their own.

In real projects, tag selection is often done after the reader type and installation method are confirmed. For this reason, Cykeo focuses on providing tags that match common reader power levels and antenna layouts. SDKs are not required for tags themselves, but basic compatibility advice can be provided when tags are used with Cykeo readers.

More about RFID Tags

Cykeo provides UHF RFID tags, HF RFID tags, UHF RFID cards and HF RFID cards. These products demonstrate exceptional reliability in applications such as logistics, supply chain, retail, manufacturing, event timing, access control, laundry management, tool tracking, and IT asset tracking.

Cykeo offer a very strong after-sales team and rapid technical support services, including support for SDKs, APIs, software integration, system development, mobile or desktop applications, as well as any related configuration or troubleshooting assistance, making your project very convenient from planning to implementation.

More About RFID Tags

UHF RFID Tags and HF RFID Tags

RFID tags are small components, but in real projects they often decide whether a system works smoothly or becomes a constant headache. CYKEO works with both UHF RFID tags and HF RFID tags because different environments demand different behavior, not one “universal” solution.

UHF RFID tags are usually chosen when distance and speed matter. They perform well in warehouses, logistics centers, and manufacturing sites where hundreds of items may need to be identified in seconds. When properly selected, UHF tags can still deliver stable reads around metal racks, cartons, and pallets, even under daily wear and tear.

HF RFID tags are more controlled by design. They are commonly used for access control, libraries, medical tracking, and applications where close-range accuracy matters more than raw speed. HF tags are less sensitive to interference and are often easier to manage in dense, people-heavy environments.

CYKEO focuses on tag consistency rather than exaggerated read range claims. The goal is simple: predictable performance, long service life, and compatibility with real-world readers and systems.

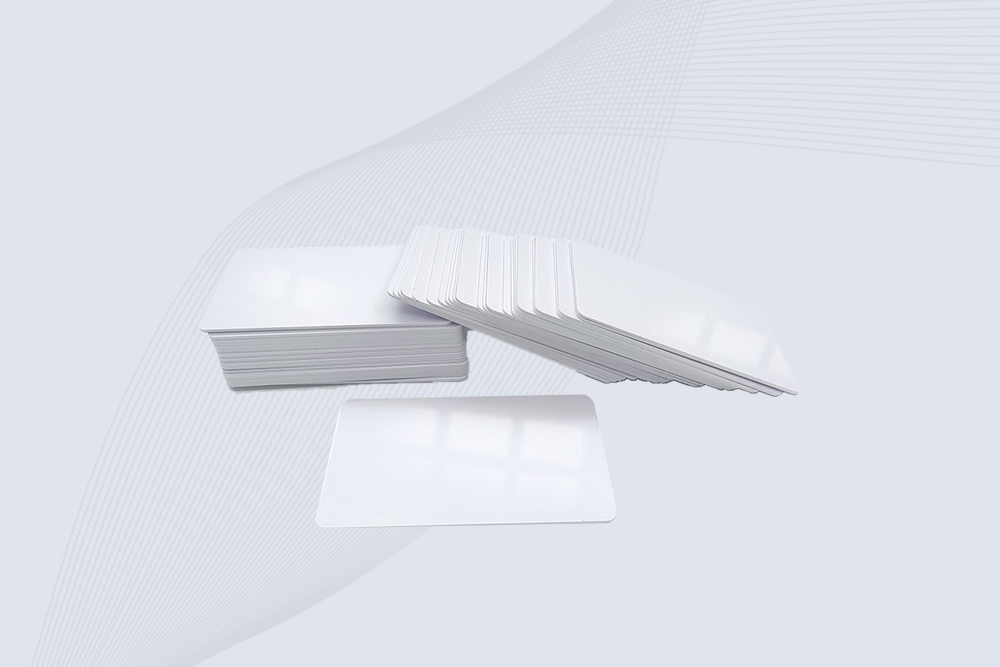

More About RFID Cards

UHF RFID Cards and HF RFID Cards

RFID cards are often the most visible part of an RFID system, yet they are usually judged only by appearance. In practice, performance over time matters far more. CYKEO designs both UHF RFID cards and HF RFID cards for everyday use, not for short-term demos. These cards are carried in pockets, tapped at entrances, stacked in card holders, and exposed to heat, humidity, and constant handling.

HF RFID cards are typically used in access control, staff identification, campuses, and membership programs. Their short read range is intentional and helps avoid unintended reads in busy environments where people pass through gates quickly or stand close together.

UHF RFID cards are chosen when longer read distance or faster batch identification is required. They are often used in asset tracking, personnel management in industrial sites, or events where hands-free identification improves efficiency.

CYKEO focuses on stable chip selection and balanced antenna design, so both card types deliver consistent reads over long service periods. These cards are made to work quietly in the background, supporting systems people depend on every day without drawing attention to themselves.

Frequently Asked Questions:RFID Tags and RFID Cards

RFID Tags FAQ

An RFID tag stores data and sends it to a reader using radio signals instead of visual scanning. Once a reader is nearby, the tag responds automatically with its ID or stored information. That means items don’t need to be picked up, turned over, or scanned one by one. In real operations, this allows staff to count cartons on a pallet, verify shipments, or locate assets in seconds. RFID also works through most packaging materials, so items can stay boxed or bagged during checks.

RFID tags can be tracked within defined areas where readers are installed. Passive tags don’t broadcast their location on their own, but they register when they pass through reader zones such as dock doors, storage areas, or exit points. This creates a reliable movement history rather than constant live tracking. For warehouses and supply chains, this “last seen” visibility is usually enough to reduce losses, confirm transfers, and understand where items tend to slow down.

RFID tag pricing varies widely depending on how they are used. Simple paper labels for cartons or retail items are the lowest cost, especially when ordered in large quantities. More durable tags designed for reuse, outdoor exposure, or metal surfaces cost more due to materials and antenna design. In practice, higher tag prices are often offset by reuse or labor savings. Large-volume projects usually see significant unit cost reductions once production scales.

Passive RFID tags don’t contain batteries. They activate only when a reader sends energy, which keeps them small, affordable, and maintenance-free. Active RFID tags include a battery and can transmit signals over much longer distances. That extra range comes at a higher cost and limited battery life. Most inventory, logistics, and retail systems rely on passive tags. Active tags are typically reserved for tracking vehicles, containers, or high-value assets across large areas.

Yes. Metal surfaces interfere with standard RFID antennas and often prevent reliable reading. Metal-mount RFID tags are designed with built-in spacing or shielding to isolate the antenna from the metal. Without this design, read rates drop sharply or fail altogether. If you are tagging tools, machines, racks, or metal containers, using standard labels usually leads to frustration. Metal-mount tags cost more but are essential for consistent performance.

One of RFID’s biggest advantages is that it doesn’t require direct visibility. Tags can be read through cardboard boxes, plastic packaging, fabric, and even wood. This allows inventory checks without opening cartons or unpacking goods. However, metal reflects signals and liquids absorb energy, which can reduce read range. Tag placement and material thickness matter. Reading through one box is easy; reading through tightly packed pallets requires planning and testing.

Read distance depends on tag size, antenna design, reader power, and the environment. Small tags are usually read at close range, while larger UHF tags can be read from several meters away. Warehouses often design systems around practical ranges rather than maximum distances to avoid unwanted reads. Nearby metal, liquids, and tag orientation all affect results. This is why real-world testing is more important than relying only on datasheet numbers.

Not all RFID tags are waterproof. Basic paper labels tolerate light moisture but are meant for dry indoor use. For harsh environments, sealed RFID tags are available with high IP ratings that protect against water, dust, and chemicals. Laundry tags are a special category, built to survive repeated washing, heat, and detergents. Choosing the wrong tag type often leads to early failure, so environment matters as much as frequency or read range.

Aluminum foil and metalized packaging can significantly reduce RFID readability. UHF RFID is especially sensitive to metal interference, as radio waves are reflected rather than absorbed. HF RFID performs better near metal but still struggles with direct contact. Products packed in foil-lined bags or anti-static materials often require tag repositioning or specialized designs. Testing is critical before large deployments, especially in food, electronics, or pharmaceutical packaging.

Passive UHF RFID tags require UHF readers operating in the 860–960 MHz range. Handheld readers are common for inventory counts and audits, offering flexibility and mobility. Fixed readers are used where automation is needed, such as dock doors or conveyor systems. Printer-encoders combine label printing and RFID encoding in one step. The best reader choice depends less on tag type and more on how scanning fits into daily workflows.

RFID tags are generally grouped into passive, active, and semi-passive types. Passive tags are the most widely used due to their simplicity and low cost. Active tags include batteries and transmit signals independently, enabling longer range tracking. Semi-passive tags use a battery to power internal functions but still rely on reader signals to communicate. Each type serves a different purpose, and most systems work best when complexity is kept to a minimum.

Passive RFID tags can last many years because they contain no batteries and have few failure points. Their lifespan is usually limited by physical wear or environmental damage rather than electronics. Active RFID tags have a defined battery life, typically several years depending on usage. In real deployments, tag durability often matters more than theoretical lifespan, especially in industrial or outdoor environments where handling is rough.

RFID Cards FAQ

RFID cards are commonly used wherever people need quick identification without contact. HF RFID cards are typical for access control, staff badges, campuses, and membership systems because they work at very short range and reduce accidental reads. UHF RFID cards are used more for asset or personnel tracking over longer distances, such as event management or controlled logistics environments. In daily use, the card is scanned hundreds or thousands of times, so reliability matters more than specs on paper.

The main difference is read range and use case. HF RFID cards operate at 13.56 MHz and are designed for close-range interaction, usually a few centimeters. UHF RFID cards operate at higher frequencies and can be read from several meters away. HF cards are better for secure access points, while UHF cards suit tracking and fast identification in open spaces. Choosing the wrong type often causes more problems than the card quality itself.

HF RFID cards are widely used in access control because the short read range gives users better control over when a card is scanned. Many systems also use encrypted chips to prevent cloning. UHF RFID cards can also be secured, but they are usually applied where speed matters more than strict access control. Security depends on the chip, system design, and reader configuration—not just the card.

A properly made RFID card can last for years. HF RFID cards used for office access or campus systems often outlive the system itself. The chip does not wear out; physical damage is usually the limiting factor. Cards stored in wallets, exposed to heat, or bent repeatedly still perform reliably when antenna tuning and lamination are done correctly, which is how CYKEO designs its cards.

Yes. Most RFID cards support common printing methods such as offset printing, thermal transfer, or inkjet personalization. HF RFID cards are often printed with photos, names, or logos for identification. UHF RFID cards may include visible IDs or color coding for quick recognition. Printing quality depends on surface material and lamination, not on the RFID technology itself.

HF RFID cards are relatively tolerant of nearby electronics and metal compared to UHF cards. UHF RFID cards can be affected by metal objects, phones, or laptops when stored closely. In real use, card orientation and placement matter. This is why testing cards in wallets or badge holders is always recommended before large rollouts.

HF RFID cards usually require intentional tapping, even through thin wallets. That’s part of their design. UHF RFID cards can sometimes be read through bags or clothing at longer distances, depending on reader power. In access control environments, HF is preferred to avoid unintended reads. In tracking applications, UHF is chosen for speed and range.

Standard RFID cards tolerate everyday moisture, sweat, and temperature changes. They are not designed for full submersion unless specifically specified. HF RFID cards used indoors rarely face issues. For outdoor or industrial use, UHF RFID cards may use thicker materials or sealed constructions. Environmental conditions should always be matched to the card design.

Most RFID cards store a unique ID, which is enough for many systems. Some HF RFID cards allow limited data storage for applications like transit or campus services. UHF RFID cards usually focus on fast identification rather than user data storage. In practice, most systems store information in the backend, not on the card itself.

HF RFID cards use the same frequency range as NFC, but interference is minimal in normal use. Smartphones won’t damage cards, and cards won’t affect phones. However, stacking multiple cards together can reduce read reliability. This applies to both HF and UHF RFID cards and is a common issue in crowded wallets.

Yes. RFID cards are designed for long-term reuse. HF RFID cards are often reassigned when staff roles change. UHF RFID cards can be reused in projects where assets or personnel rotate. Reusability depends on system permissions, not the card hardware. This makes cards a cost-effective option over time.

Start with how the card will be used, not the technology. If users must actively present the card at close range, HF RFID cards are usually the right choice. If fast identification at distance is required, UHF RFID cards make more sense. CYKEO typically recommends testing both in real conditions before final selection, because environment and workflow matter more than theory.

Cykeo RFID IoT Solution Products R&D Manufacturer

Cykeo RFID IoT Solution Products R&D Manufacturer