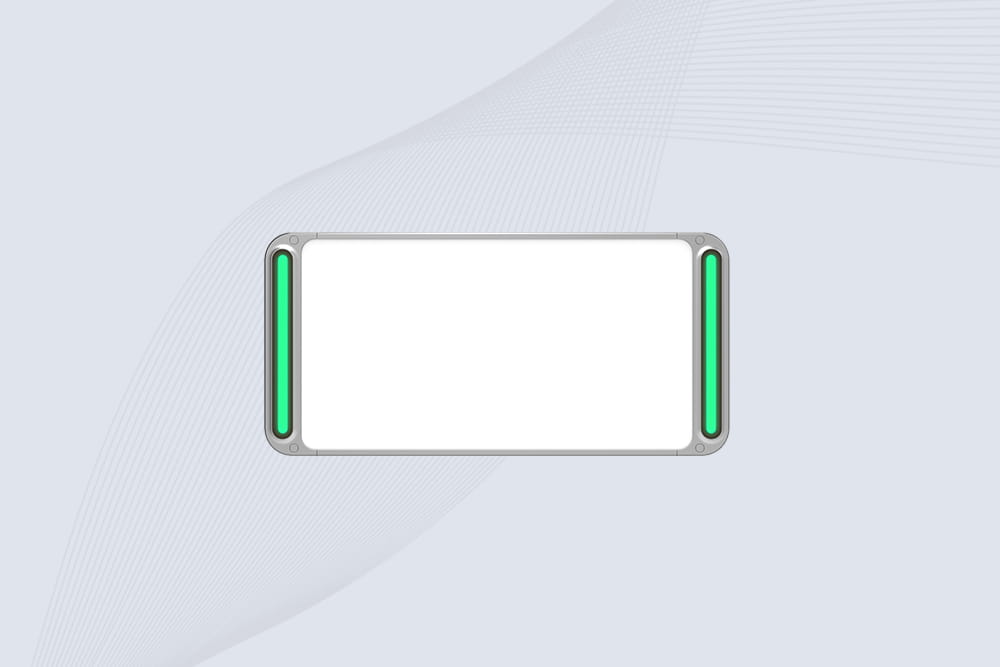

Cykeo RFID Gate Readers

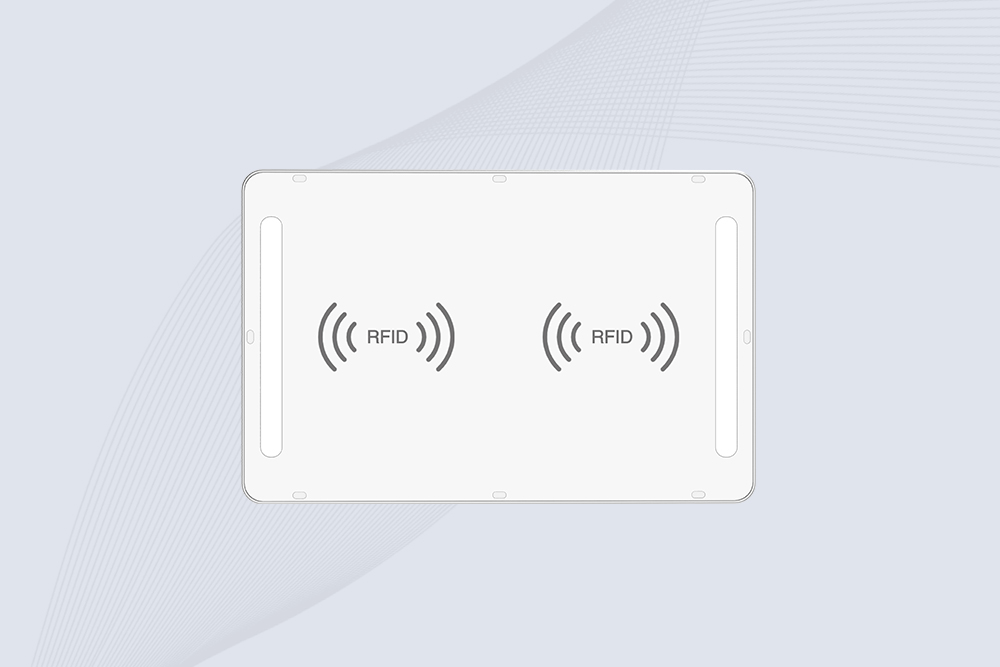

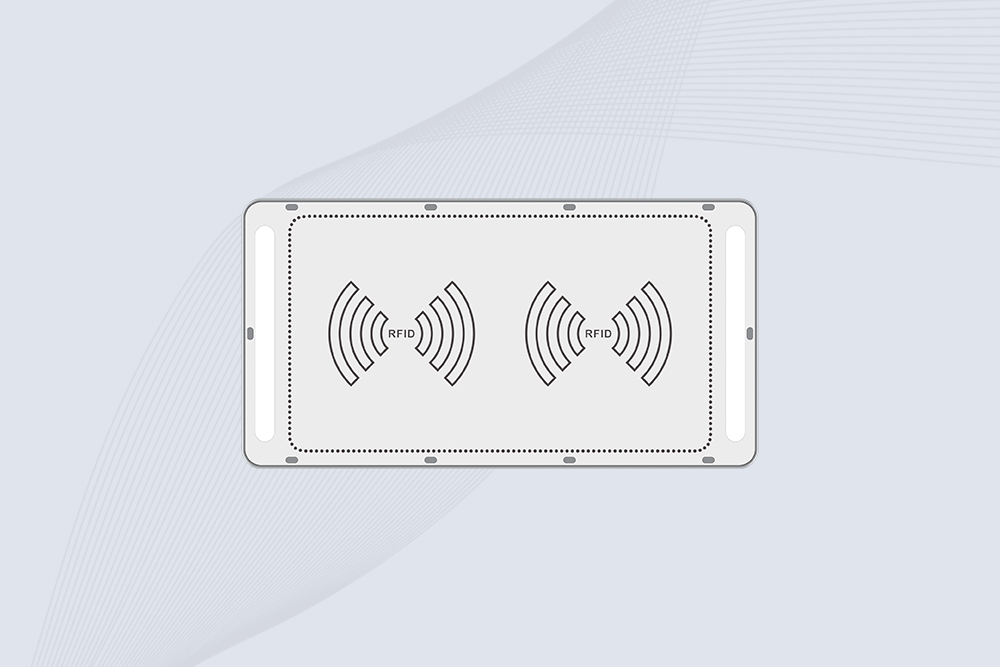

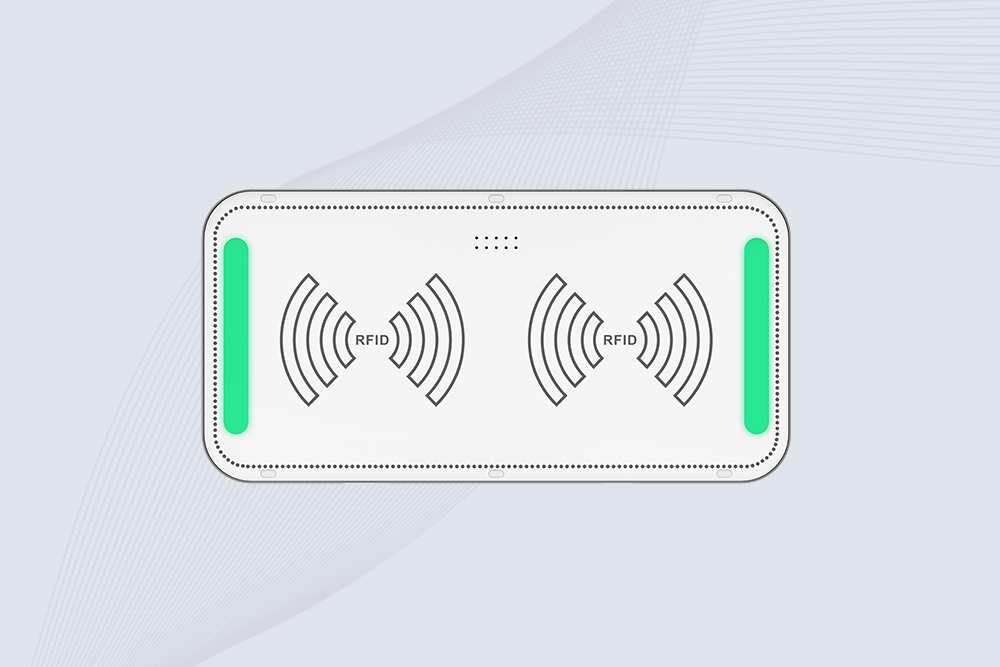

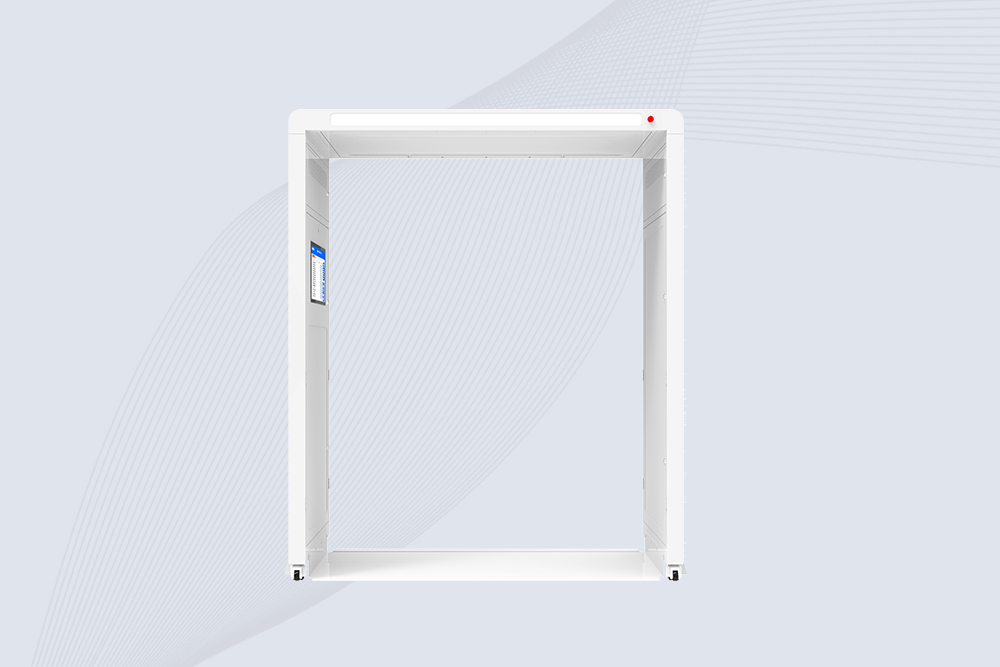

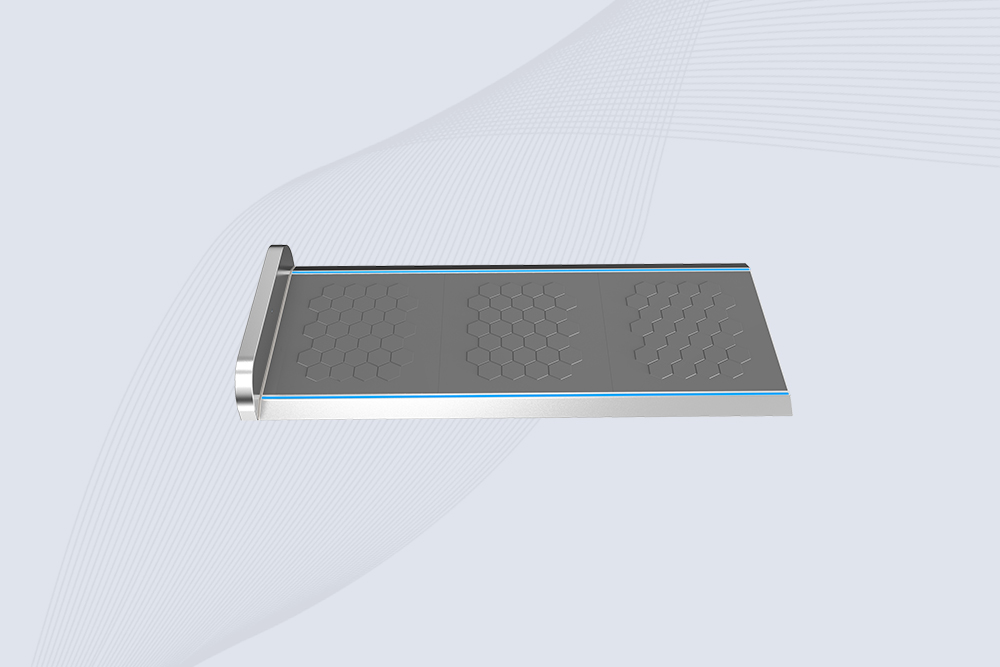

Cykeo offers RFID gate readers for fixed passage identification in logistics, access control and asset flow monitoring. The product range includes RFID Portal Readers, Ceiling-Mounted RFID Gate Readers and Wall-Mounted RFID Gate Readers, suitable for different installation environments.

SDKs, APIs and demo software are available to support fast integration with existing software systems. For gate width, antenna layout or installation method selection, Cykeo’s engineering team can provide basic technical guidance.

More About RFID Gate Readers

CYKEO RFID Gate Readers, also known as RFID Portal Readers, are designed for places where items move continuously and manual scanning simply doesn’t work anymore. You see them most often at warehouse exits, dock doors, production transfer points, and controlled access areas.

View more

Instead of relying on staff to stop, scan, or double-check labels, gate readers identify tagged items automatically as they pass through. Once installed, the system works quietly in the background. Pallets, cartons, or assets are captured in real time without interrupting normal workflows.

CYKEO gate readers are built to stay stable under daily industrial conditions. Dense tag populations, metal racking, forklifts, and high traffic volumes are expected, not exceptions. With open SDKs and flexible interfaces, customers integrate the readers into WMS, MES, or custom platforms without locking themselves into fixed logic.

Cykeo offer a very strong after-sales team and rapid technical support services, including support for SDKs, APIs, software integration, system development, mobile or desktop applications, as well as any related configuration or troubleshooting assistance, making your project very convenient from planning to implementation.

More About RFID Gate Readers

RFID Gate Readers are usually chosen when accuracy at transition points matters more than raw read distance. These readers are installed where goods physically move from one process to another — for example, from storage to shipping, or from production to packaging.

CYKEO RFID Gate Readers focus on controlled read zones. The goal is not to read everything everywhere, but to read the right items at the right moment. Directional antennas, adjustable power levels, and timing filters help reduce false reads and duplicate data.

In real projects, most tuning happens after installation. Once optimized, the system requires very little attention. Operators don’t interact with the reader directly, which reduces human error. Over time, this automation delivers cleaner inventory data and fewer disputes between systems and physical stock.

More About RFID Portal Readers

RFID Portal Readers are essentially the same technology, viewed from a system design perspective rather than a physical one. The word “portal” highlights the idea of a logical checkpoint — a place where items are expected to be seen, recorded, and confirmed.

CYKEO RFID Portal Readers are often used when companies want traceability without slowing down operations. Trucks passing through yard entrances, pallets leaving a warehouse, or materials entering a controlled zone can all be tracked automatically.

What matters most here is consistency. A portal reader should behave the same way every day, regardless of lighting, dust, or operator habits. CYKEO designs its portal solutions to stay predictable over long periods, so system data reflects reality instead of creating noise that needs constant cleanup.

Frequently Asked Questions:RFID Gate Readers

An RFID Gate Reader is designed to work at fixed transition points where items physically pass through, such as dock doors, warehouse exits, or production handover zones. Unlike handheld or desktop readers, it doesn’t rely on an operator to aim or trigger a scan.

In practice, the reader works automatically in the background. As tagged items move through the gate, the system captures data without stopping the flow. RFID Portal Readers follow the same concept, but the term “portal” usually emphasizes system logic rather than the physical frame. The main difference is not hardware power, but how the reader is deployed and controlled.

Most CYKEO RFID Gate Readers are installed at locations where goods naturally slow down or pass through a defined space. Common examples include dock doors, conveyor transfer points, cleanroom entrances, and warehouse zone boundaries.

These are places where manual scanning would interrupt operations or simply be ignored under pressure. By fixing the reader in position, the system removes human behavior from the equation. In some projects, RFID Portal Readers are installed without visible gates at all, using walls or ceilings to define the read zone. The physical layout always depends on how goods actually move, not on theory.

Technically, yes — the core technology is the same. The difference is mostly how people describe the system. “Gate reader” usually refers to the physical setup, including frames, antennas, and mounting structures. “Portal reader” focuses more on the logical checkpoint in the system.

In real projects, CYKEO often uses both terms interchangeably. What matters more is how the read zone is controlled. A portal that reads too much data creates confusion, not value. Whether you call it a gate or a portal, the design goal is always clean, predictable reads at a specific point in the process.

Accuracy depends more on setup than on raw reader specifications. In busy warehouses with forklifts, metal racks, and dense tag populations, poorly tuned systems will struggle. CYKEO RFID Gate Readers are designed to allow fine adjustment of power, antenna orientation, and timing filters.

During commissioning, engineers usually spend time reducing cross-reads and duplicate events. Once that work is done, accuracy becomes very stable. In many sites, gate readers operate for months without adjustment. This is why real-world testing matters more than lab numbers when evaluating RFID Portal Reader performance.

Yes, but they need to be designed and configured properly. Metal is a constant factor in logistics and manufacturing, not a special case. CYKEO RFID Gate Readers are often paired with metal-mount RFID tags and directional antennas to control reflections.

Instead of trying to read everything at maximum power, the system focuses on defining a narrow, predictable read zone. In metal-heavy environments, less power often delivers better results. Portal readers installed near steel doors or conveyors usually require on-site tuning, but once adjusted, performance remains consistent.

Not completely. They serve different purposes. RFID Gate Readers automate fixed checkpoints, while handheld readers are still useful for exception handling, audits, and mobile tasks.

In many CYKEO deployments, both exist side by side. The gate reader captures routine movements automatically, and handheld devices are used when staff need to investigate discrepancies or locate specific items. RFID Portal Readers reduce workload, but they don’t eliminate the need for human tools. Instead, they shift labor from repetitive scanning to problem-solving.

Integration is usually easier than customers expect, but it depends on how clean the existing system architecture is. CYKEO provides open SDKs, APIs, and sample data formats so developers can control logic on their side.

The reader itself focuses on reliable data capture, not business rules. That separation helps long-term flexibility. RFID Portal Readers often send raw events, and filtering happens at the software layer. This approach avoids hardcoding assumptions into hardware, which is a common cause of failure in large RFID projects.

Once installed and tuned, RFID Gate Readers require surprisingly little maintenance. There are no moving parts, and firmware updates are infrequent. Most issues arise from environmental changes rather than hardware failure.

For example, adding metal racks near a portal or changing traffic flow can affect read behavior. Regular visual inspections and occasional performance checks are usually enough. CYKEO designs gate readers for long-term uptime, knowing that access to dock doors or production lines is limited during normal operations.

Yes, direction detection is one of the most valuable features when implemented correctly. By using multiple antennas and timing logic, CYKEO RFID Gate Readers can determine whether items are entering or leaving a zone.

This is especially important for inventory accuracy. Without direction control, systems quickly accumulate errors. RFID Portal Readers often use software-level filtering combined with antenna placement to achieve this. Direction detection is not automatic — it must be designed into the layout from the beginning.

RFID Portal Readers make sense when speed, volume, and consistency matter more than individual scans. If items move frequently and stopping them causes delays or mistakes, a portal approach usually pays for itself quickly.

CYKEO often recommends portal readers for dock doors, production transitions, and controlled access points. They are not the cheapest RFID option upfront, but they reduce labor dependency and data errors over time. In many cases, the real return comes from fewer disputes between system records and physical reality.

Cykeo RFID IoT Solution Products R&D Manufacturer

Cykeo RFID IoT Solution Products R&D Manufacturer