RFID Door Reader: The Key to Solving Warehouse Efficiency Bottlenecks

129RFID door reader solutions for warehouses and factories. Supports UHF RFID gate readers, ceiling tunnel readers, and seamless WMS integration.

MoreAll RFID Product

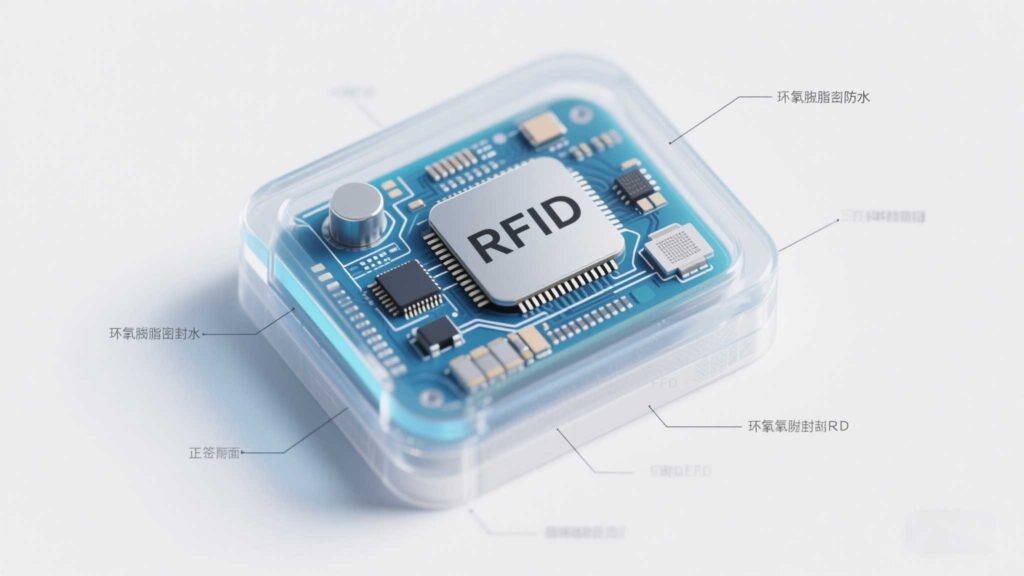

Tracking assets outdoors is like trying to read a book in a hurricane—wind, rain, and dirt conspire to ruin your day. Standard RFID modules fail here, but waterproof designs thrive. Whether you’re monitoring construction equipment, shipping containers, or agricultural tools, this guide reveals how to build a weatherproof RFID system that works when storms hit.

Case Study: A wind farm using Cykeo’s IP68 modules cut turbine part losses by 60% despite coastal salt spray.

a. Ingress Protection (IP) Ratings

b. Material Durability

c. Temperature Resilience

Look for:

Pro Tip: Test tags in your harshest environment for 2–4 weeks before full deployment.

Step 1: Positioning Readers

Step 2: Cable Management

Step 3: Tag Placement

Example: Cykeo’s marine-grade readers helped a ferry operator track lifejackets across 20 vessels, reducing loss rates by 75%.

Takeaway: Waterproof RFID modules are non-negotiable for outdoor asset tracking. By prioritizing IP67+/IP68 ratings, rugged materials, and smart installation, you’ll build a system that laughs off storms, mud, and salt spray. Start with a pilot—tag 10–20 high-value assets—and expand as confidence grows. Remember: paying a 20% premium for durability today can save 200% in replacements tomorrow.

RFID door reader solutions for warehouses and factories. Supports UHF RFID gate readers, ceiling tunnel readers, and seamless WMS integration.

MoreExplore how NFC phones can be used as RFID tags for efficient asset management and tracking. Learn the differences between NFC and RFID technologies, and discover the benefits of combining both in real-world applications. Check out our guide and e...

MoreCykeo's IoT-enabled RFID systems reduce factory downtime by 63%. Learn how real-time tracking & predictive maintenance are transforming automotive & electronics manufacturing.

MoreDiscover whether RFID readers can detect tag distance, the technologies involved, and real-world applications. Learn how Cykeo’s solutions enable precise RFID tracking.

More