What’s the Lifespan of an RFID Reader? Maintenance Tips to Prolong It

692What’s the average RFID reader lifespan? Learn key factors affecting durability and practical maintenance tips to extend its operational life.

MoreAll RFID Product

As global research and testing demands grow, efficient and precise laboratory management becomes a key factor in enhancing competitiveness. Traditional laboratory management methods, such as manual records and barcode scanning, face issues like low efficiency and human error, especially when dealing with large volumes of samples and precision instruments. RFID technology has emerged as a game-changing solution, gradually becoming a must-have technology for research and testing institutions.

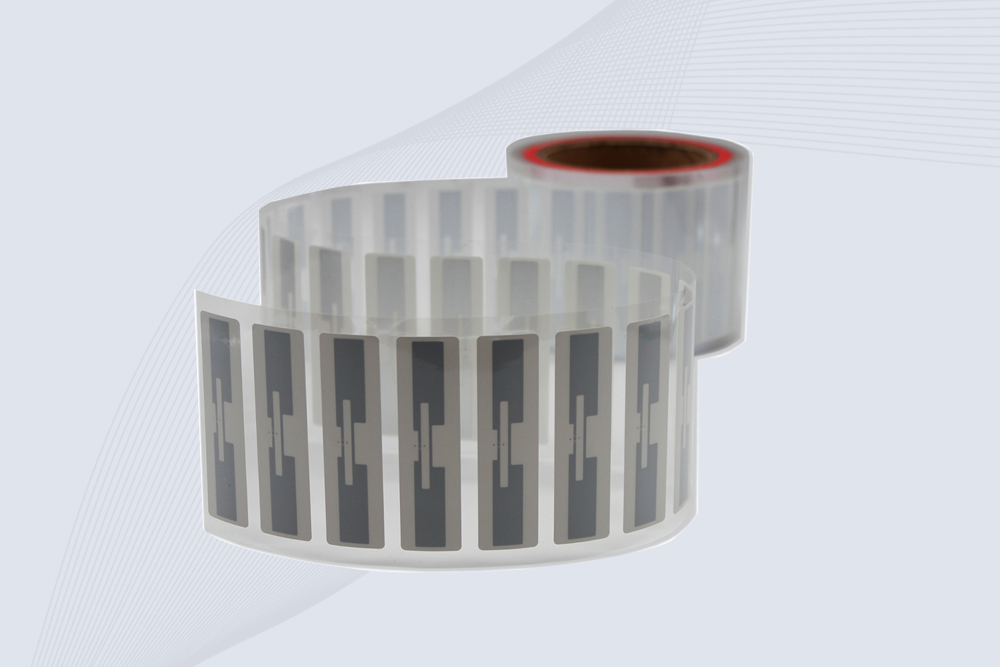

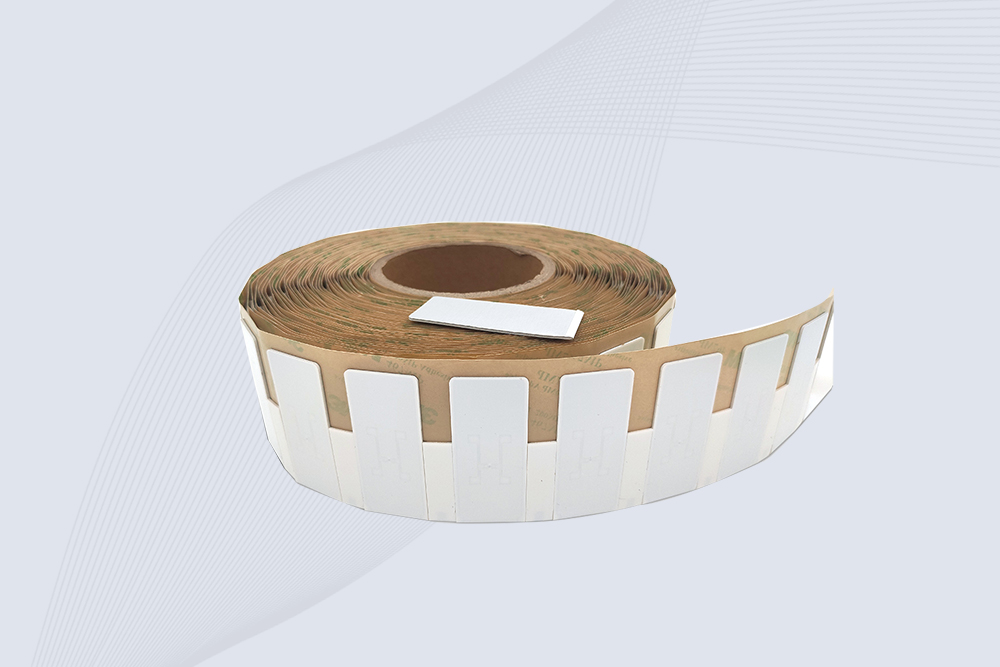

Laboratory RFID technology applies RFID to laboratory settings by attaching or embedding RFID tags on sample containers, laboratory equipment, reagent bottles, etc. The system uses readers to wirelessly read and write tag information, enabling fast identification, location tracking, and monitoring of objects. RFID tags are known for their large storage capacity, rewritability, strong anti-interference, and ability to work in harsh environments. When combined with management software, RFID technology helps create a complete, intelligent laboratory management system.

In a laboratory, the accuracy of samples and the proper functioning of equipment directly impact the reliability of test reports and the timeliness of order delivery. In traditional management, manual record-keeping often results in missed or incorrect information during sample handling. Moreover, it’s challenging to monitor equipment maintenance and calibration cycles accurately, which can lead to delays if the equipment malfunctions. Additionally, international research collaborations or product testing increasingly require traceability of samples and experimental data. RFID technology addresses these needs, helping to avoid business losses due to management lapses.

When selecting an RFID solution for laboratories, consider the compatibility of the tags with the laboratory environment, such as resistance to chemical corrosion or high temperatures. Additionally, ensure that the readers’ range and speed meet practical needs. The management software should integrate smoothly with existing laboratory information management systems (LIMS). It’s also essential to choose a vendor with extensive experience in RFID for laboratories, ensuring smooth installation, setup, and timely resolution of any issues that arise.

After a medical device testing laboratory adopted RFID technology, the sample loss rate decreased by 90%, and delays in testing progress were reduced by 70%. The laboratory gained more client orders due to the efficient and precise testing services. A biopharmaceutical company applied RFID to manage laboratory equipment and reagents, saving over one million dollars annually in equipment maintenance and reagent waste, while accelerating new drug development. These cases demonstrate RFID’s significant value in the field of laboratory management.

In today’s rapidly advancing technology landscape, RFID provides an efficient, precise, and intelligent solution for laboratory management. From sample tracking to equipment management, inventory control to efficiency boosts, RFID technology helps laboratories upgrade their management systems. Choosing the right RFID solution will help businesses stand out in the global research and testing market and achieve high-quality growth.

CYKEO Passive RFID Tags are made for wet and high-humidity environments where standard labels do not last. This rfid passive tag is often used around liquids, chemicals and temperature changes, providing stable reading distance and long data life for industrial tracking.

CYKEO CK-BQ1504 Metal RFID Tags is a compact anti-metal UHF RFID solution built for direct mounting on metal surfaces. With stable 8-meter read range, Ucode-8 chip, and long data retention, this rfid metal tag fits tools, containers, automotive parts, and industrial asset tracking.

CYKEO CK-BQ7020 On-Metal RFID Tags are designed for reliable tracking on steel and metal surfaces. Built with an FR4 epoxy body and industrial-grade chips, these On-Metal RFID Tags deliver stable performance, long data life, and chemical resistance, making them a dependable RFID anti-metal tag for harsh environments.

The CYKEO CK-BQ6025 Anti-Metal RFID Tag is built for metal surfaces where standard tags fail. Designed for long-range performance, harsh environments, and stable data retention, this Anti-Metal RFID Tag is ideal for industrial assets, containers, and equipment tracking using on metal RFID tags.

What’s the average RFID reader lifespan? Learn key factors affecting durability and practical maintenance tips to extend its operational life.

MoreAvoid costly errors with handheld RFID scanners! Learn common mistakes like poor tag placement, interference issues, and how to optimize scans.

MoreDiscover how an RFID antenna works as the critical translator in your system. Learn about signal transmission, power harvesting, and data collection in simple terms.

MoreTired of manual asset counts and missing equipment? Our complete RFID solution combines Cykeo's reliable tags & readers with the Tagmatiks cloud platform for end-to-end, automated asset management. Boost efficiency and cut costs.

More