What Type of Antenna Do RFID Tags Use? Your Pocket Guide.

65Confused about what type of antenna RFID tags use? We explain the key designs—coils for proximity and dipoles for long-range UHF tracking—and how to choose.

MoreAll RFID Product

Walk into a modern factory floor and it might look calm — just shelves, conveyors, and a few status lights blinking quietly. But behind that calm rhythm, there’s a silent guardian keeping everything in check — the RFID stationary reader. It doesn’t move, it doesn’t talk, yet it’s the one making sure the entire workflow actually runs the way it should.

An RFID stationary reader, sometimes called a fixed reader, is basically the eyes of the system. You mount it once — above a conveyor, next to a dock door, or on a wall — and it just keeps watching. Constantly.

Unlike a handheld scanner, there’s no button to press, no person needed to walk around and wave it at boxes. It just lives there, quietly reading every tag that crosses its line of sight, feeding data straight into the system.

In logistics, movement can be the enemy of efficiency. Sure, a handheld reader gives flexibility, but imagine scanning a thousand pallets manually every single day. That’s where a stationary reader earns its value.

It’s built for automation — covering a wide zone, picking up hundreds of tags per second, and syncing instantly with the backend. You don’t “use” it so much as you trust it to be part of the infrastructure.

Where handheld readers depend on people, stationary systems don’t wait around. They create an always-on feedback loop. A tagged box rolls past? The reader catches it instantly. Inventory updates happen in real time. Production data doesn’t need verification later — it’s already accurate the first time.

In warehouses, you’ll find stationary readers sitting above dock doors or gate points, automatically logging what enters and what leaves. No scanning guns, no waiting.

On production lines, they’re placed near conveyors to confirm each part is where it should be, keeping assembly flow clean and traceable.

In retail, they’re often hidden inside shelves or checkout counters, quietly tracking items and preventing those awkward “out of stock but system says available” moments.

And in hospitals, these devices track valuable equipment or even patient tags — not as surveillance, but as safety assurance. No more lost wheelchairs or misplaced surgical kits.

Setting up a stationary RFID reader isn’t just screwing it into a wall and plugging it in. There’s real engineering behind it — field geometry, antenna orientation, and environmental interference.

Metal racks can mess with signals, temperature swings can alter read range, and electromagnetic noise from machinery can cause blind spots.

That’s why installers often say they “paint with radio waves.” The goal is to shape the invisible field so every tag, whether it’s on a steel bin or a moving pallet, can be picked up cleanly.

When it’s tuned right, the system almost disappears — it just works. You don’t have to think about it. It becomes part of the environment, like air conditioning or Wi-Fi — invisible but essential.

It’s not really about which one is better — it’s about what kind of rhythm your operation runs on.

If your workflow depends on mobility — walking aisles, doing spot checks, or handling small batches — a handheld reader is great.

But if you’re managing bulk movement, 24/7 tracking, or automated logistics, a stationary setup wins every time.

Yes, it costs more upfront and needs some installation effort, but that’s the price of automation. In the long run, it pays itself back with accuracy, speed, and the beautiful thing every manager wants: reliability without extra labor.

The funny thing about RFID stationary readers is that they never move — yet they keep everything else moving smoothly.

They are the quiet operators of the digital warehouse, the translators between physical assets and real-time data.

“Stationary” might sound boring, but in the world of automation, it’s the still things that actually keep the world spinning.

Cykeo CK-C1 industrial Forklift RFID Reader features 20m read range, 600 tags/sec scanning, Impinj R2000 chipset, and IP67 rugged design. Ideal for warehouse logistics and manufacturing. Supports ISO 18000-6C/6B protocols.

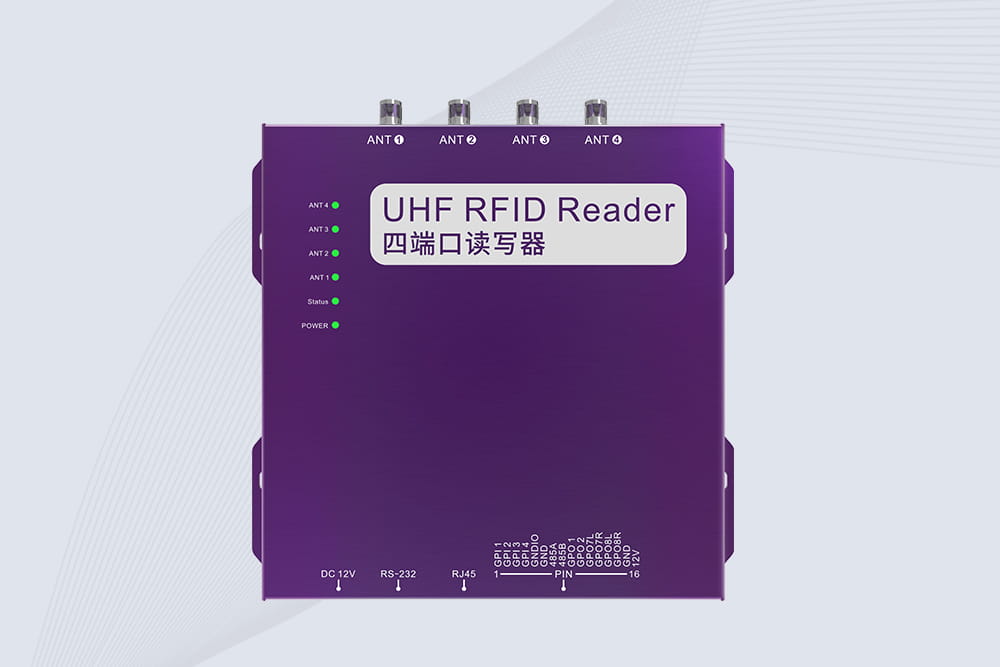

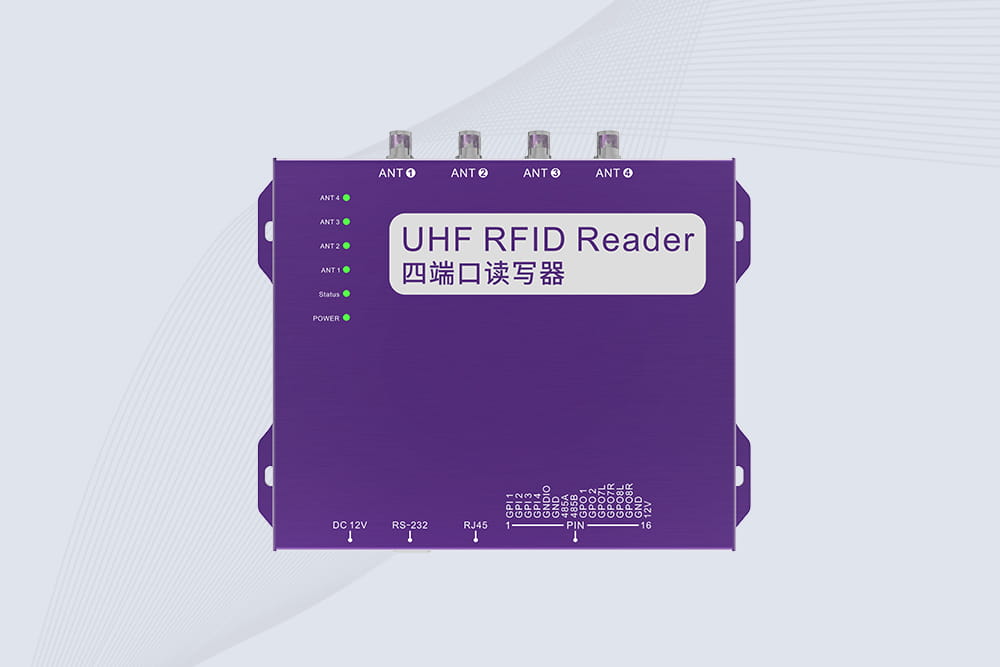

Cykeo CYKEO-R4 industrial UHF RFID Fixed Reader features 4 TNC ports, 400+ tags/sec speed, IP67 housing, and global frequency compliance for vehicle inspection, smart warehouse, and asset management systems.

Cykeo’s CYKEO-R4L 4-port Fixed UHF RFID Reader delivers 400 tags/sec scanning, ISO 18000-6C compliance, and IP65 protection. Ideal for warehouse automation, manufacturing WIP tracking, and logistics management.

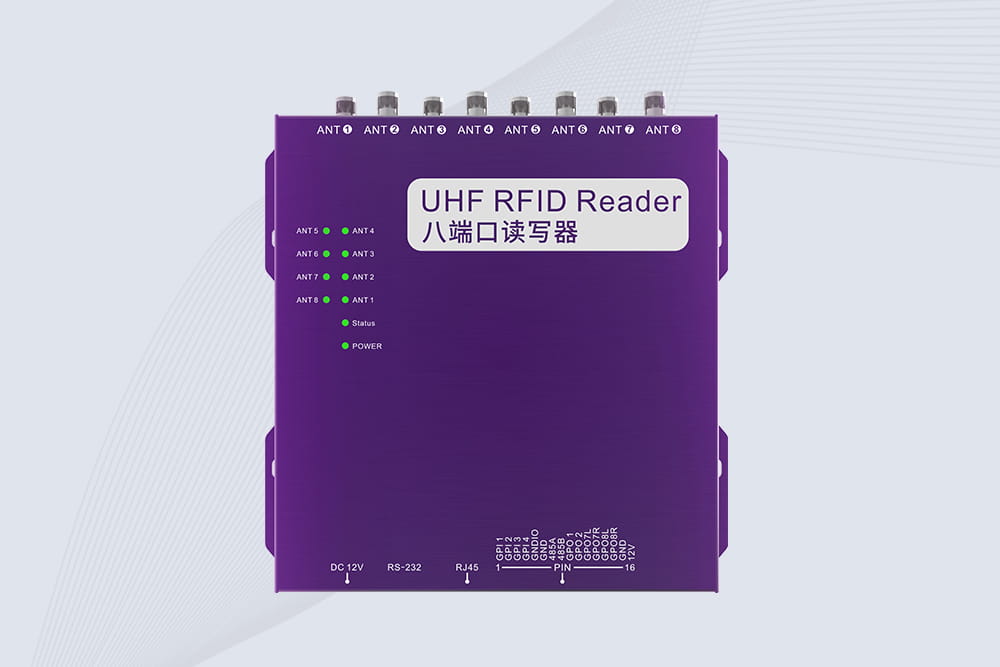

CYKEO CYKEO-R8L Fixed RFID Reader with 8-port UHF design, Impinj-based RF core and up to 20m read range. An industrial Fixed RFID Reader for vehicle inspection, warehouse portals, smart manufacturing lines and secure access checkpoints.

Confused about what type of antenna RFID tags use? We explain the key designs—coils for proximity and dipoles for long-range UHF tracking—and how to choose.

MoreDiscover waterproof handheld RFID scanners built for rugged outdoor environments. Learn how Cykeo’s durable devices enhance accuracy in harsh weather and dust.

MoreRfid School Attendance System, with its advanced technology and innovative management approach, is rapidly becoming a preferred choice in the education sector.

MoreStruggling with RFID reader connectivity issues? Learn how to diagnose and fix common problems like signal loss, IP conflicts, and interference.

More