How to Optimize Fixed RFID Readers for High-Speed Conveyor Belts?

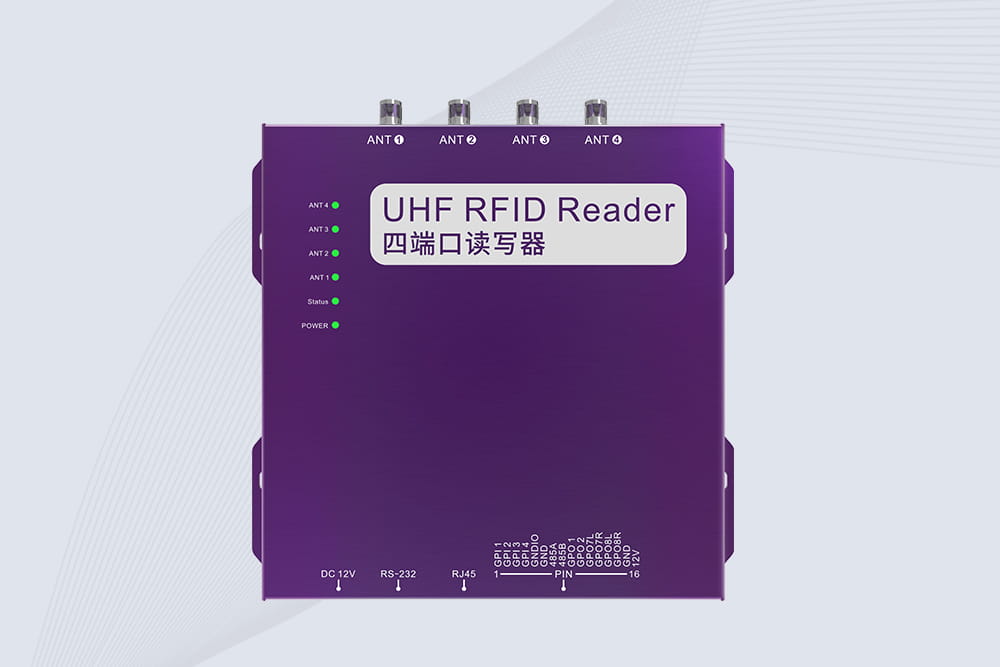

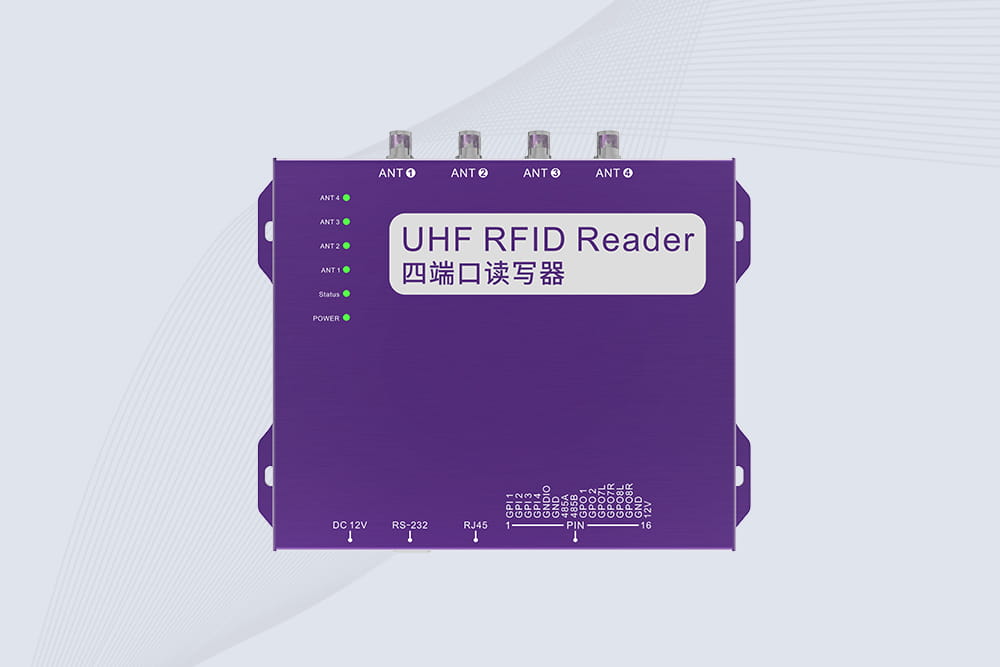

High-speed conveyor belts (e.g., in logistics, manufacturing) demand RFID systems capable of reading tags at speeds exceeding 5–10 m/s with near-100% accuracy. Cykeo’s industrial-grade RFID solutions are engineered for these challenges. Below is a step-by-step guide to optimizing fixed RFID readers for fast-moving workflows.

1. Antenna Placement & Angle

- Positioning:

- Mount antennas 10–30 cm above the conveyor belt to minimize read distance variance.

- For tags on curved surfaces (e.g., bottles), angle antennas 15°–30° to maximize signal reflection.

- Multi-Antenna Arrays:

- Deploy Cykeo’s dual-antenna setups on both sides of the belt to capture tags regardless of orientation.

2. Tag Selection & Placement

- High-Speed Tags:

- Use Cykeo’s High-Velocity Tags with rapid wake-up times (<2 ms) and small memory footprints.

- For metal or liquid-packed items, choose on-metal or inlay tags with tuned impedance.

- Consistent Positioning:

- Affix tags to flat, non-metallic areas (e.g., label side of boxes) 5–10 cm from edges to avoid shadow zones.

3. Anti-Collision & Reader Settings

- Dense Reader Mode (DRM):

- Activate DRM in Cykeo’s software to stagger read cycles and reduce interference in multi-reader zones.

- Session & Query Settings:

- Use Session S2 and Query 5/8 for fast-moving tags (prioritizes new tags over duplicates).

- Adjust Transmit Power (30–33 dBm) and Receive Sensitivity to balance range and noise.

4. Synchronization with Conveyor Speed

- Encoder Integration:

- Connect Cykeo readers to conveyor encoders to trigger reads at precise intervals (e.g., every 10 cm).

- Use real-time speed feedback to dynamically adjust read cycles during acceleration/deceleration.

- Buffered Read Points:

- Install redundant antennas at entry/exit points to re-capture missed tags.

5. Environmental Optimization

- EMI Mitigation:

- Shield cables and readers from motor noise using ferrite cores and grounded enclosures.

- Maintain a 50+ cm gap between antennas and metal conveyor frames.

- Lighting:

- Avoid fluorescent/LED lights near antennas; they can introduce RF interference.

6. Software & Data Handling

- Edge Computing:

- Process reads locally using Cykeo’s Edge Processor to filter duplicates and transmit only actionable data.

- Integration:

- Sync Cykeo’s API with WMS/MES systems (e.g., SAP EWM, Oracle) for real-time inventory updates.

Case Study: 99.7% Read Rate at 8 m/s

- Challenge: A European e-commerce hub needed to track 5,000 packages/hour at 8 m/s.

- Solution:

- Deployed Cykeo’s dual-antenna arrays with encoder synchronization.

- Used High-Velocity Tags and Session S2 settings.

- Result:

- 99.7% read accuracy and 30% reduction in manual re-scans.

optimize RFID readers for conveyor belts

Cykeo RFID IoT Solution Products R&D Manufacturer

Cykeo RFID IoT Solution Products R&D Manufacturer