What Makes an RFID Solution Truly Medical-Grade?

655Considering an RFID solution medical? Learn how healthcare systems use RFID to track equipment, ensure compliance, and reduce operational costs.

MoreAll RFID Product

Let’s be honest — no one likes the idea of being “tracked.”

But in factories, hospitals, logistics yards, and even office towers, the RFID employee tracking system isn’t about spying — it’s about keeping people safe, organized, and accountable in the chaos of daily operations.

Walk into any busy manufacturing floor or construction site. You’ll see the same problem everywhere — people constantly moving, entering restricted areas, or scrambling during an emergency. Traditionally, supervisors relied on clipboards, radio calls, and guesswork to figure out who was where.

Now imagine a simple badge or wristband that quietly records where each person enters or exits — not to judge them, but to make sure everyone’s accounted for. That’s the heart of RFID employee tracking system.

Each employee wears a small tag that communicates with readers placed at doorways, gates, or zones. The software behind the scenes turns this data into a living map — who’s in Zone A, who’s in the warehouse, who just left for lunch. It’s like having eyes across the entire site, minus the invasive cameras.

In a fire or gas leak, seconds matter. One of the most powerful uses of an RFID system is mustering — instantly seeing who’s still inside.

Instead of counting heads in the parking lot, managers can pull up a dashboard and know exactly who’s missing and where they last checked in.

For high-risk environments like oil refineries or underground tunnels, that’s not just convenient — it’s life-saving.

And even in lower-risk environments, it’s still valuable. Think of hospitals during shift changes, or large campuses during emergencies. The ability to know — without guessing — who’s on-site is an operational superpower.

Of course, there’s a catch: tracking raises eyebrows. No one wants to feel like a barcode.

That’s why the human side matters more than the tech itself. Companies that deploy these systems successfully usually do one thing right — they’re transparent. They tell employees exactly what’s being tracked (and why), they limit data retention, and they keep the focus on safety and efficiency, not micromanagement.

Because truthfully, when the system works right, it helps employees too. It automatically logs attendance, reduces the headache of manual sign-ins, and even protects workers during emergencies. It’s not surveillance — it’s structure.

What’s fascinating about RFID systems is how they turn movement into insight.

After just a few weeks of data, patterns start to appear:

That’s not just “tracking” — it’s understanding how your workplace breathes. With that knowledge, managers can redesign workflows, move equipment, or balance teams more efficiently. It’s operational psychology in action.

It’s worth saying: these systems aren’t perfect.

RFID readers sometimes miss a tag swipe, or a worker’s badge might get buried under a heavy jacket. Building-wide coverage takes planning, cabling, and sometimes hundreds of antennas.

But compared to old-school paper attendance or manual mustering, the difference is night and day. Instead of hoping everyone’s safe, you know. Instead of guessing where a bottleneck happens, you see it.

The RFID employee tracking system isn’t loud or flashy. It’s the silent infrastructure that makes modern workplaces safer, faster, and smarter.

In the same way barcode scanners changed logistics, RFID is now reshaping how organizations understand their most unpredictable element — people.

In five years, this won’t even be called “tracking” anymore. It’ll just be how workplaces breathe, record, and protect their people — quietly, invisibly, and with purpose.

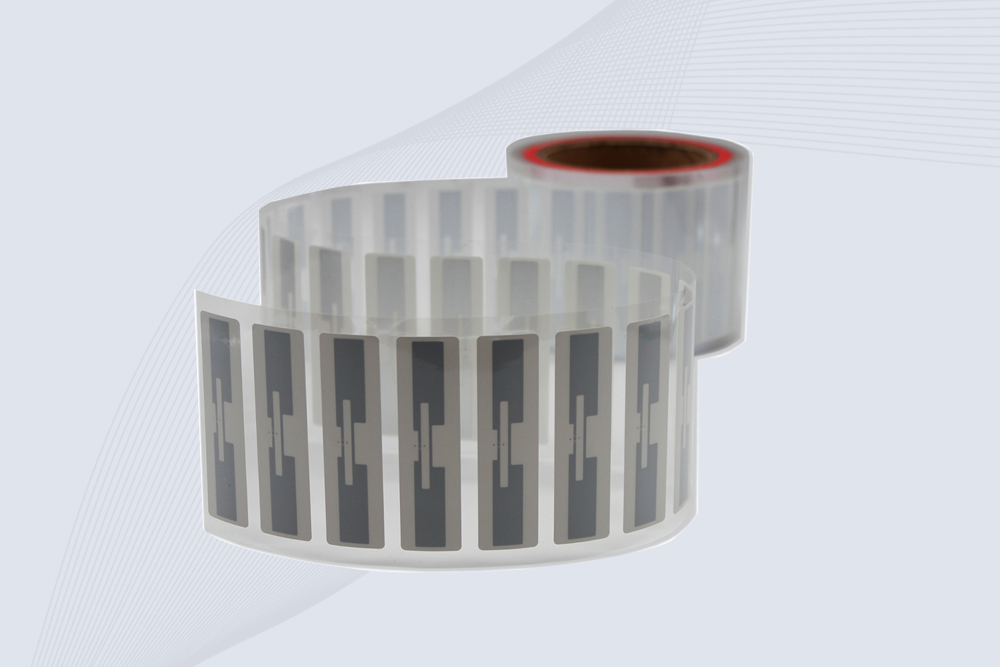

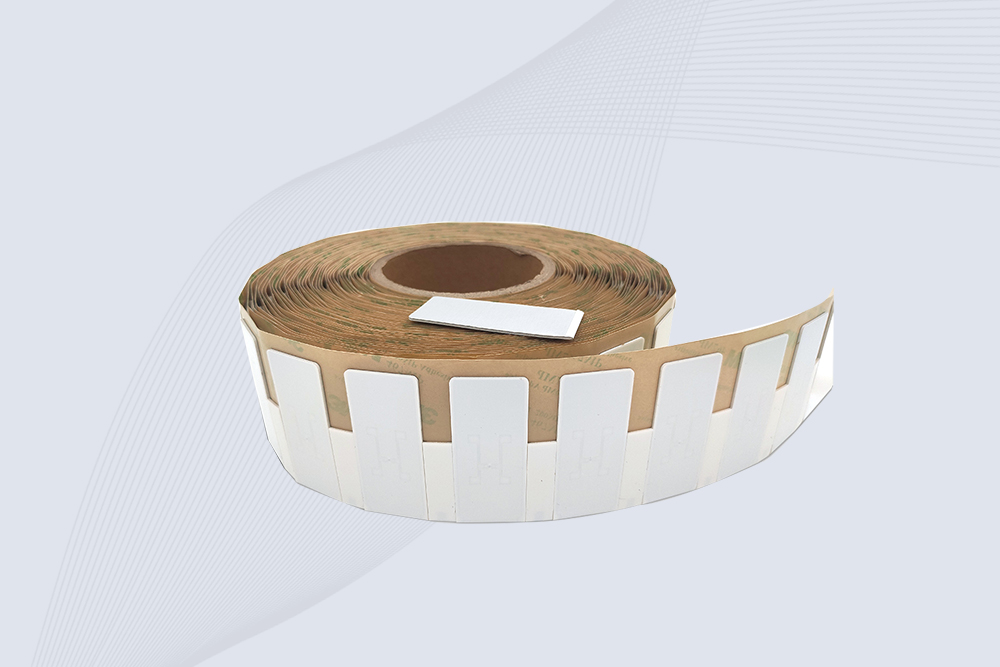

CYKEO Passive RFID Tags are made for wet and high-humidity environments where standard labels do not last. This rfid passive tag is often used around liquids, chemicals and temperature changes, providing stable reading distance and long data life for industrial tracking.

CYKEO CK-BQ1504 Metal RFID Tags is a compact anti-metal UHF RFID solution built for direct mounting on metal surfaces. With stable 8-meter read range, Ucode-8 chip, and long data retention, this rfid metal tag fits tools, containers, automotive parts, and industrial asset tracking.

CYKEO CK-BQ7020 On-Metal RFID Tags are designed for reliable tracking on steel and metal surfaces. Built with an FR4 epoxy body and industrial-grade chips, these On-Metal RFID Tags deliver stable performance, long data life, and chemical resistance, making them a dependable RFID anti-metal tag for harsh environments.

The CYKEO CK-BQ6025 Anti-Metal RFID Tag is built for metal surfaces where standard tags fail. Designed for long-range performance, harsh environments, and stable data retention, this Anti-Metal RFID Tag is ideal for industrial assets, containers, and equipment tracking using on metal RFID tags.

Considering an RFID solution medical? Learn how healthcare systems use RFID to track equipment, ensure compliance, and reduce operational costs.

MoreCompare QR codes and NFC/RFID tags for your business. Discover their pros and cons in cost, security, and usability to choose the right identification technology.

MoreStruggling to choose between RFID and Bluetooth beacons? We compare range, cost, accuracy, and real-world use cases to help you decide.

MoreLearn how to link RFID tag IDs to data in a MySQL database for asset tracking, inventory management, and more. Follow step-by-step integration tips with Cykeo’s solutions.

More