Can RFID Handheld Readers Scan Tags Through Metal or Liquid Containers?

1065Learn if RFID handheld readers can scan tags through metal or liquid containers. Discover solutions for interference and Cykeo’s industrial-grade scanning technology.

MoreAll RFID Product

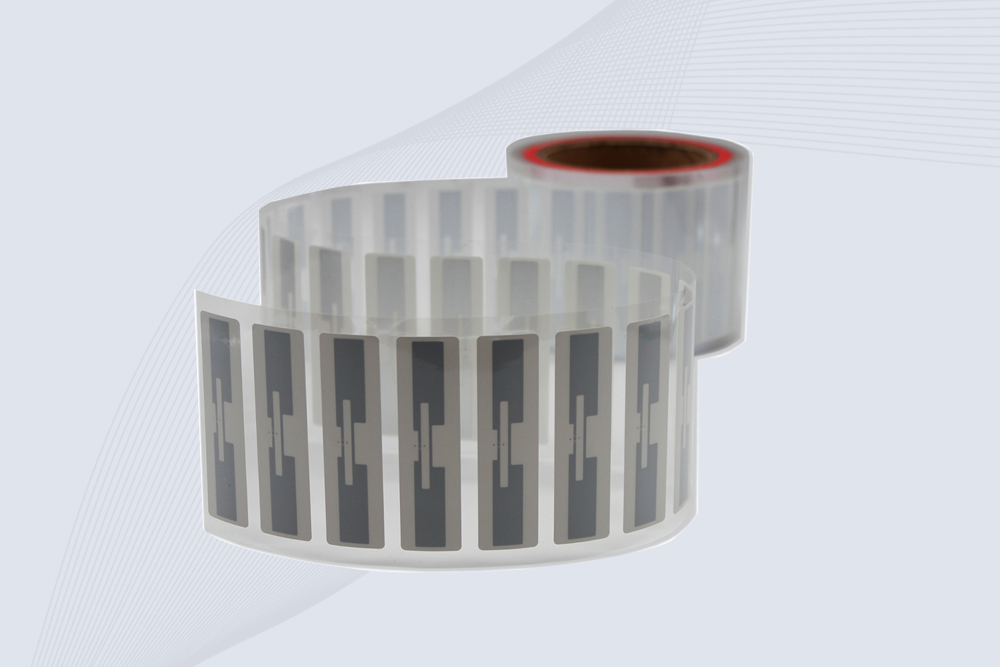

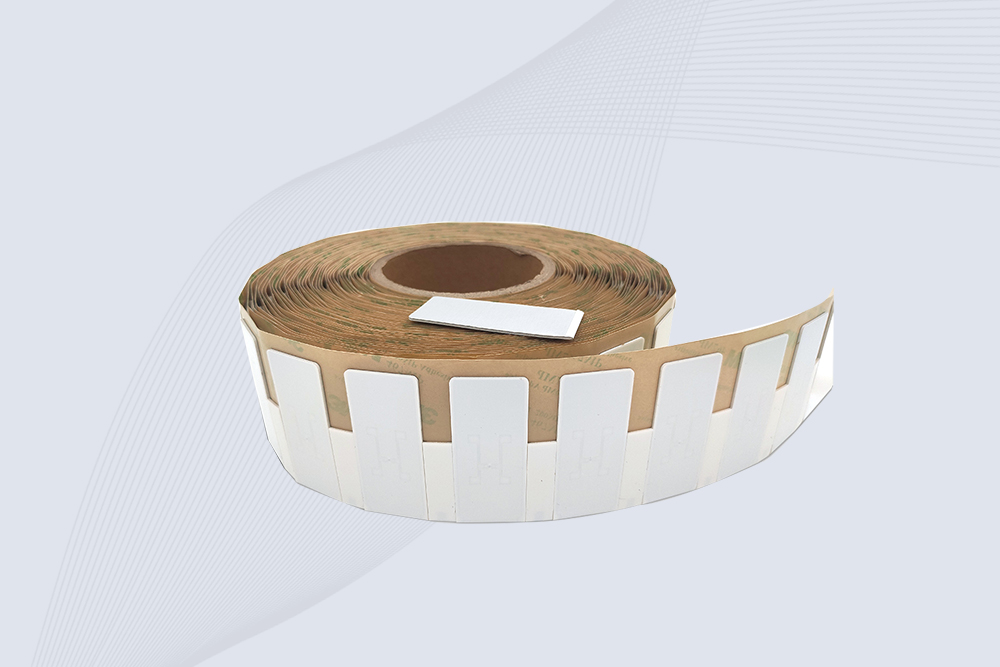

RFID inventory stickers (rfid stickers for inventory) are radio-frequency identification labels used in stock management. They integrate an RFID chip and flexible antenna within a sticker form, which can be attached to item surfaces to enable non-contact data reading. Compared with traditional barcodes, RFID stickers offer advantages such as longer reading distances, batch reading capability, and no line-of-sight requirement, making them particularly suitable for fast inventory counts and accurate tracking in medium to large-scale stock environments.

To adapt to different item materials and environments, RFID stickers can be divided into several types. The common inventory tag types and their features include:

The core of choosing RFID inventory stickers lies in their functional value, mainly including:

| Function | Description |

|---|---|

| Batch Reading | Simultaneously identify multiple tags, improving counting efficiency |

| Long-Distance Reading | Typical read range between 3–10 meters, some scenarios up to 15 meters |

| Non-Contact Operation | No scanning or line-of-sight needed, enhancing operational convenience |

| Data Writing & Encryption | Supports user-defined data writing to ensure data security |

| Integration with Inventory Systems | Can connect with ERP, WMS, and other systems for synchronized data |

RFID stickers are widely applied in multiple industries for inventory management, including but not limited to:

Each scenario may have different requirements for tag material, reading distance, and adhesion method; appropriate product parameters should be selected according to actual needs.

When choosing RFID inventory stickers, the following dimensions are recommended for evaluation:

| Dimension | Evaluation Points |

|---|---|

| Usage Environment | Is it high temperature, humid, metal interference, or outdoor exposure? |

| Surface Material | Is it plastic, paper, glass, or metal? |

| Tag Size | Is a micro tag or standard size required? |

| Reading Performance | Is long-distance reading or strong anti-interference needed? |

| System Compatibility | Can it integrate with existing software systems? |

RFID stickers for inventory, as an efficient and automated identification method, are playing an increasingly central role in enterprise inventory management. Through reasonable selection and system integration, enterprises can achieve inventory transparency, real-time data, and automated management. Whether for basic product counting or industrial equipment tracking, flexibly configured RFID stickers can bring significant efficiency improvements.

CYKEO Passive RFID Tags are made for wet and high-humidity environments where standard labels do not last. This rfid passive tag is often used around liquids, chemicals and temperature changes, providing stable reading distance and long data life for industrial tracking.

CYKEO CK-BQ1504 Metal RFID Tags is a compact anti-metal UHF RFID solution built for direct mounting on metal surfaces. With stable 8-meter read range, Ucode-8 chip, and long data retention, this rfid metal tag fits tools, containers, automotive parts, and industrial asset tracking.

CYKEO CK-BQ7020 On-Metal RFID Tags are designed for reliable tracking on steel and metal surfaces. Built with an FR4 epoxy body and industrial-grade chips, these On-Metal RFID Tags deliver stable performance, long data life, and chemical resistance, making them a dependable RFID anti-metal tag for harsh environments.

The CYKEO CK-BQ6025 Anti-Metal RFID Tag is built for metal surfaces where standard tags fail. Designed for long-range performance, harsh environments, and stable data retention, this Anti-Metal RFID Tag is ideal for industrial assets, containers, and equipment tracking using on metal RFID tags.

Learn if RFID handheld readers can scan tags through metal or liquid containers. Discover solutions for interference and Cykeo’s industrial-grade scanning technology.

MoreDiscover Cykeo CK-B2G, a rugged UHF RFID handheld reader with 20m range, Android 13 OS, 12-hour battery life, and multi-protocol support. Perfect for logistics, warehousing, and retail.

MoreDiscover how RFID technology improves patient safety, tracks critical medical equipment, and cuts hospital costs. Learn about real-world healthcare RFID solutions.

MoreGet past the theory. See exactly what is RFID antenna used for in daily operations—from speeding up shipping to stopping theft. Learn why it’s your system's workhorse.

More