RFID on Metal: Why Your Tags Go Silent and How to Fix It

We’ve all been there. You need to track expensive metal tools or server racks, so you order standard RFID labels. You stick one on a wrench or a server cabinet, wave the reader, and… nothing. Silence. It’s frustrating, but it’s not a defect—it’s physics. The solution isn’t a louder reader; it’s a completely different kind of tag built around a compact uhf rfid tag antenna design for metallic objects. Let’s break down why regular tags fail and how the right design turns a problem into a reliable data point.

The Simple Reason Standard Tags Fail on Your Tools

First, understanding why RFID tags fail on metal is key. Think of a standard UHF tag antenna as a tiny, finely tuned harp. It’s designed to resonate and “sing” (broadcast its signal) in open air. When you place it directly against metal, that metal surface acts like a massive, disruptive soundboard. It reflects and scrambles the RF energy, completely detuning your delicate harp. The tag can’t establish the proper electromagnetic field to communicate. It’s not broken; it’s just being smothered.

How the Right Tag Works With the Metal, Not Against It

A functional on-metal tag doesn’t just work despite the metal; it’s engineered to use it. The core of a compact uhf rfid tag antenna design for metallic objects involves two clever tricks:

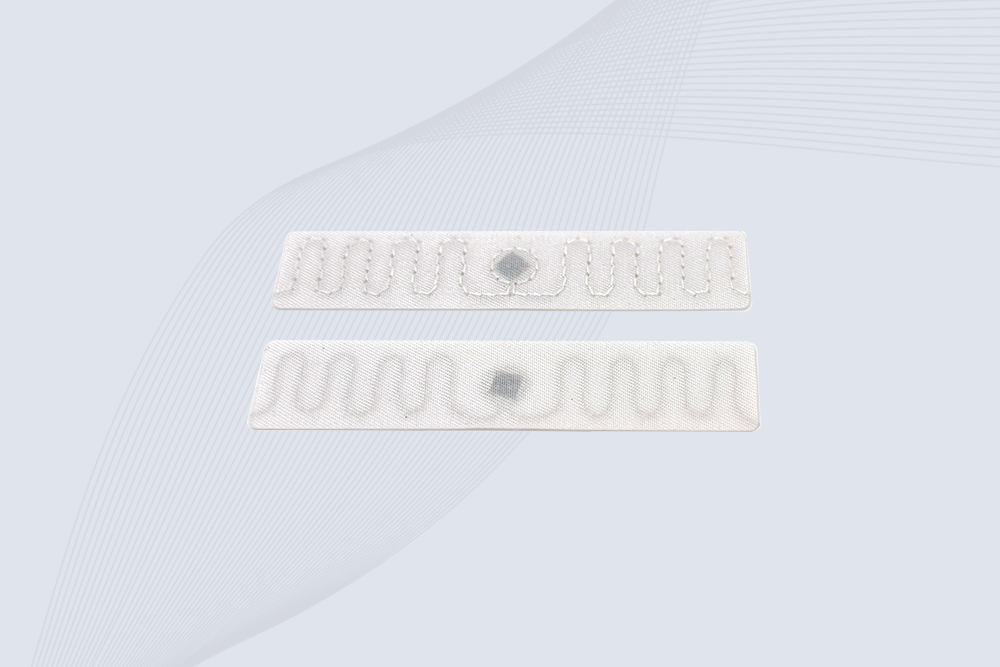

- The Essential Air Gap: The tag is never just an adhesive sticker. Inside its rugged casing, there’s a proprietary foam or plastic layer that acts as a mandatory spacer. This lifts the antenna circuit a critical few millimeters off the metal, creating the tiny cavity of air it needs to “breathe” and resonate.

- Turning the Enemy into a Booster: The antenna pattern is completely re-calculated from the ground up. Designers treat the metal surface as a “ground plane”—a foundational part of the antenna system itself. When done right, the metal actually reflects and focuses the radio waves away from the surface, often creating a more predictable and robust read zone than a tag in free space would have.

The result is what you need: reliable metal mount RFID tag performance on drill presses, server blades, and medical carts.

Picking the Winner: What to Look For in the Field

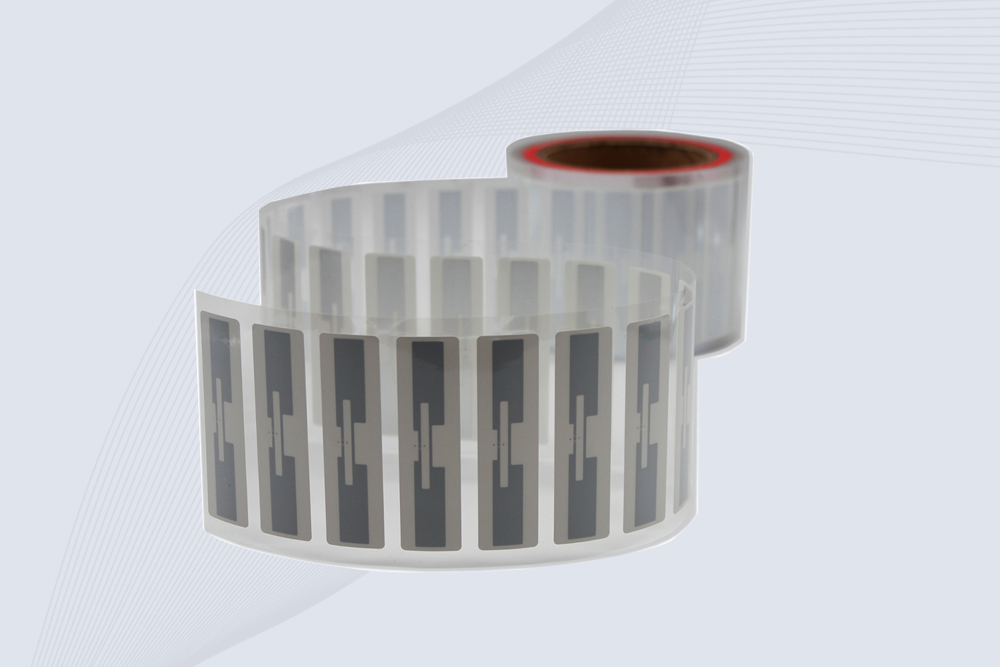

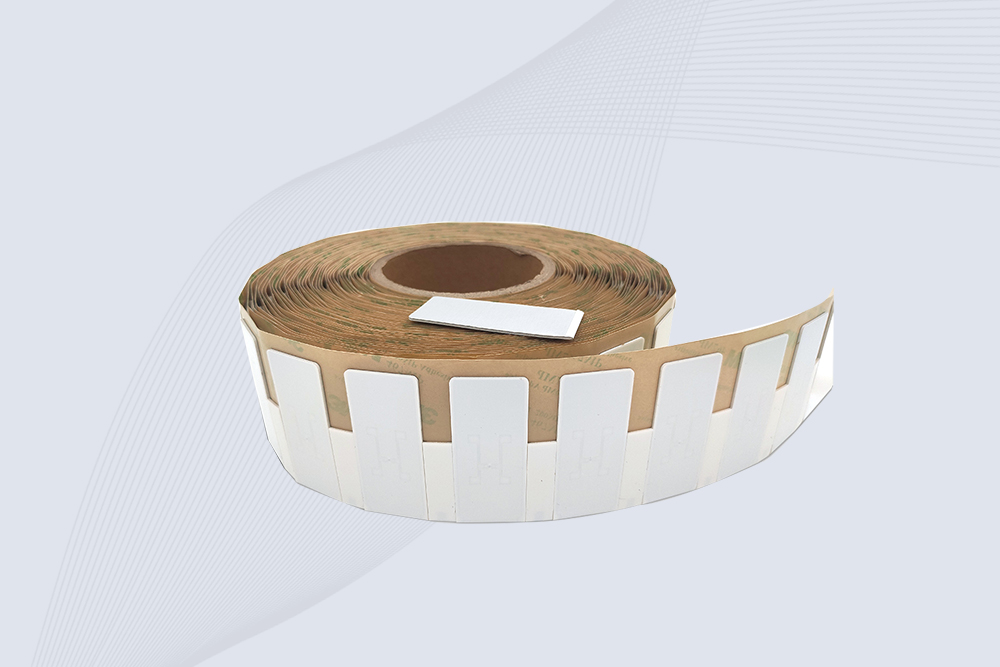

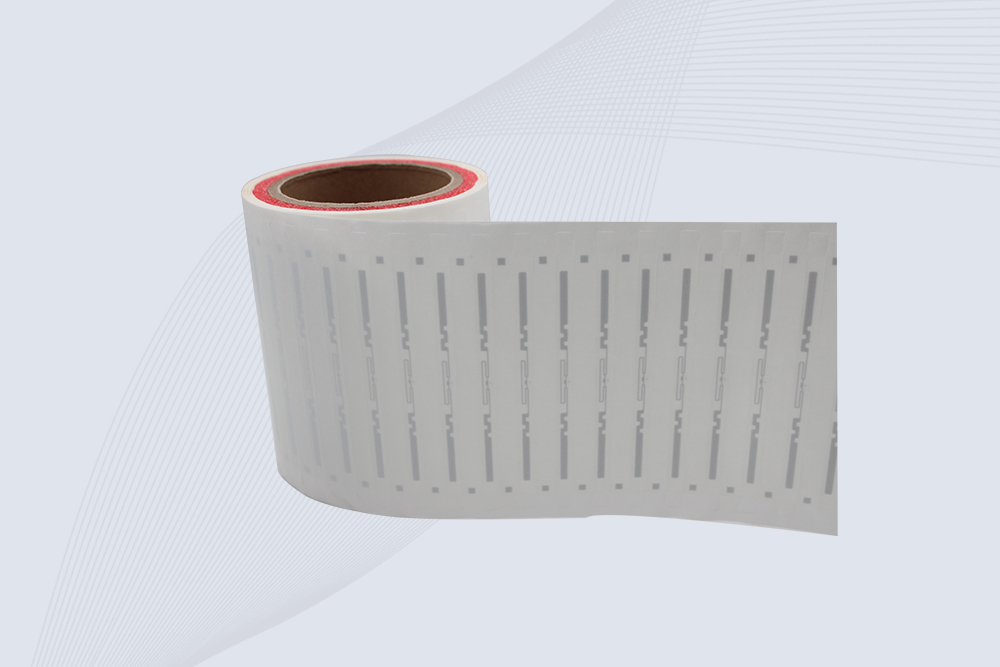

Selecting RFID tags for metal surfaces is a practical decision. Here are best practices for metal mount rfid tags we’ve learned from deployments:

- Size vs. Performance: Yes, you want it compact. But the smallest tag may sacrifice read range. For a small tool, a 30mm tag might be perfect. For a large metal pallet in a yard, a larger 100mm tag will give you the distance you need.

- The “Toughness” Specs: Look beyond the adhesive. Is the housing ABS plastic or epoxy resin? Does it have an IP68 rating for washdown environments or outdoor use? Can it handle chemical splash or UV exposure? For rugged on-metal tag solutions CYKEO designs, we prioritize these material specs because the assets themselves live hard lives.

- Test on Your Actual Stuff: This is non-negotiable. Before you buy 10,000 tags, get a sample pack. Stick them on your actual assets—a greasy wrench, a textured server panel, a painted forklift mast—and test them in the real environment. See how the read range holds up. A good tag will perform consistently.

Where These Tags Are Non-Negotiable

You use these when the asset is metal and the tracking needs to be bulletproof: in tool cribs for construction and aviation MRO, on data center hardware for automated inventory, on metal returnable transport items (RTIs) in automotive plants, and on surgical instrument trays that undergo sterilization.

So, when you need a compact uhf rfid tag antenna design for metallic objects, you’re not just buying a sticker. You’re investing in a purpose-built RF engineering solution that transforms a challenging surface into your most reliable tracking point.

Cykeo RFID IoT Solution Products R&D Manufacturer

Cykeo RFID IoT Solution Products R&D Manufacturer