RFID Reader in Mobile: Can a Phone Really Do the Job?

19RFID reader in mobile devices explained with real use cases, limits, and solutions. Learn how professionals use mobile RFID readers with CYKEO.

MoreAll RFID Product

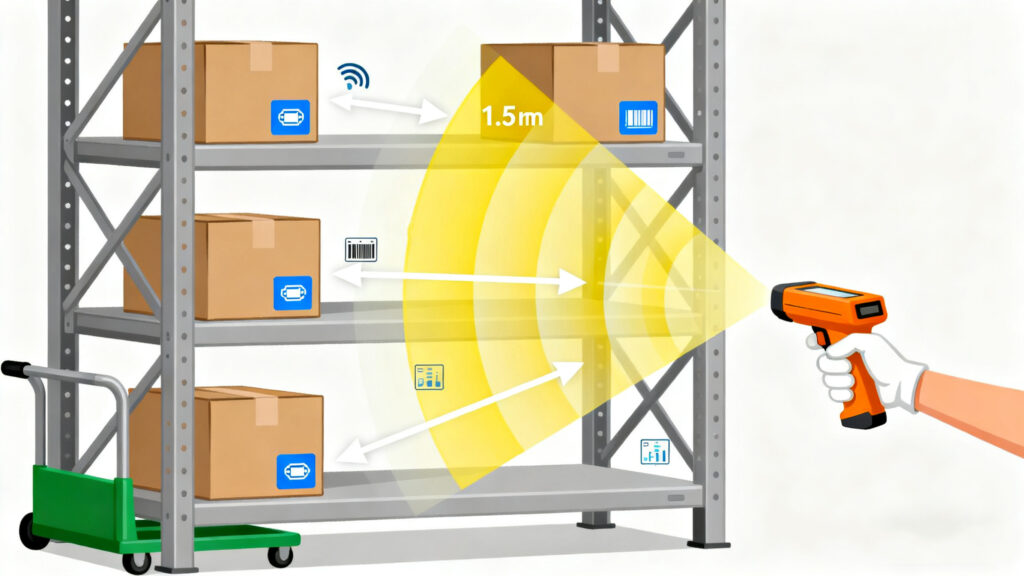

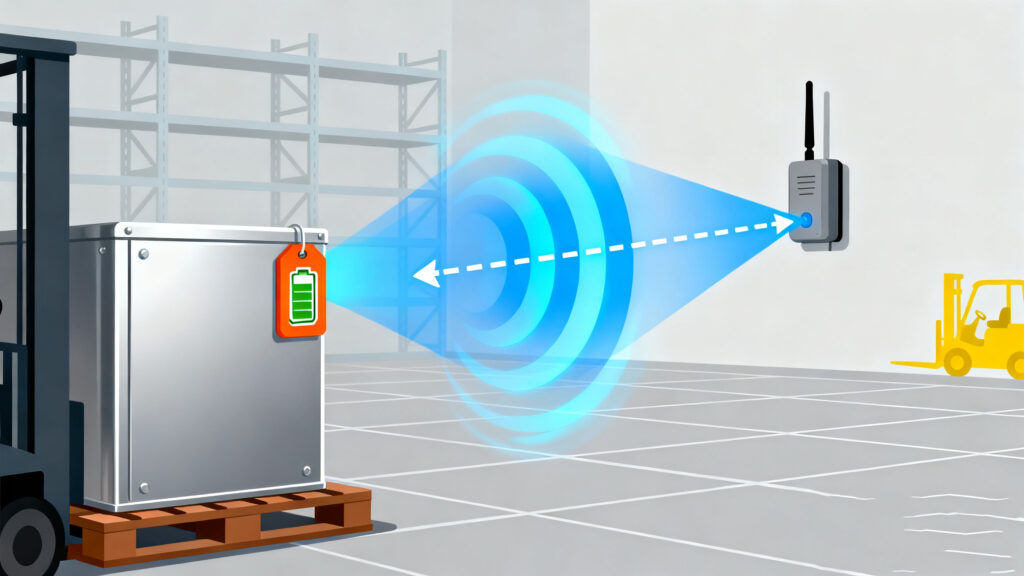

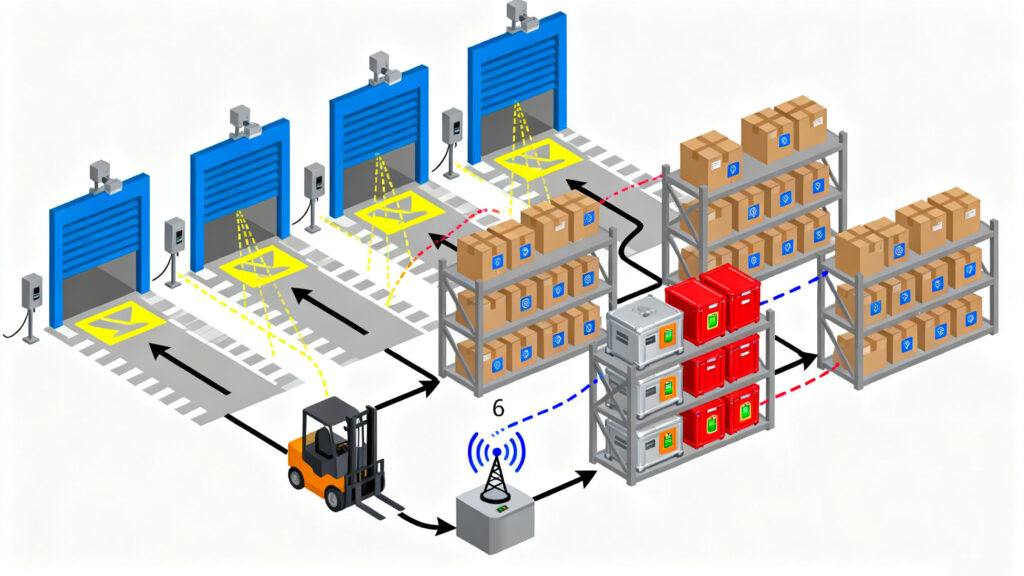

Imagine each item in your warehouse having a little “voice” that can talk to your system. That’s what RFID does. Instead of scanning barcodes one by one, RFID tags automatically communicate with readers. The moment a pallet moves, or a box passes a dock, your system instantly knows where it is.

For software providers, this means plugging those “voices” into your WMS or ERP so managers can make fast decisions without chasing down every single item.

RFID really shines when it comes to cutting down manual work:

For software providers, all this data flows into dashboards so managers can spot issues quickly and fine-tune warehouse workflows.

Software systems need to handle both, interpret signals, remove duplicates, and update the WMS in real time.

RFID isn’t magic. There are a few things to consider:

RFID cuts down human mistakes in a few key ways:

Software providers can turn these signals into automated rules, alerts, and dashboards that make it easy to act fast.

Yes, you don’t have to scrap your WMS or ERP. RFID readers feed signals to your system, which then:

APIs and dashboards let managers see what’s happening in real time, instead of waiting for manual updates.

Barcodes are fine for small operations, but RFID is a game-changer when things scale:

For software providers, this is the sweet spot—you can build dashboards, predictive alerts, and optimization tools on top of raw RFID signals.

Raw RFID signals are like chatter—you need software to turn it into useful information:

Without this layer, RFID tags just “talk”—no one’s really listening intelligently.

RFID is more than a tracking tool—it’s a way to make smarter, faster decisions in a warehouse. Managers can see bottlenecks, predict shortages, and improve storage layouts. For software providers, it’s an opportunity to offer dashboards, workflow automation, and predictive analytics that turn RFID signals into actionable insights.

With the right software, warehouses aren’t just reacting—they’re proactively managing operations. Passive and active RFID tags combined with smart software give real-time visibility, reduce errors, and optimize labor. In short, RFID plus software is a powerful, connected warehouse strategy.

Cykeo CK-C2 UHF RFID inventory cart features 10 UHF readers, 500 tags/sec scanning, Windows/Android OS, and hybrid power for warehouses/libraries. Supports ISO 18000-6C protocols and customization.

Cykeo’s industrial RFID Inventory Tracking station features dual scanning modes, 200+ items/sec bulk reading, and SAP integration for precise warehouse management. MIL-STD-810G certified with Windows/Android OS.

Cykeo CK-D7L RFID system for inventory offers 40+ tags/sec scanning, 150L secure storage, and Impinj R2000 chipset for warehouses, toolrooms, and retail. Global frequency compliance (840-960MHz).

Cykeo CK-C1 mobile RFID scanner cart features PLC-controlled antenna lifting, 10-tag/sec reading, and 21.5″ touchscreen for libraries, hospitals, and warehouses. Supports Windows/Android and multi-protocol RFID.

RFID reader in mobile devices explained with real use cases, limits, and solutions. Learn how professionals use mobile RFID readers with CYKEO.

MoreDiscover how a hospital parking system using RFID improves emergency vehicle access, speeds up gate operations, and organizes staff and visitor parking through touchless automation and smart data tracking.

MoreDiscover how Cykeo's new Beijing branch delivers cutting-edge RFID technology and tailored IoT solutions across six North China provinces, driving industrial digitalization with 48-hour delivery assurance.

MoreDiscover how fixed RFID readers enhance manufacturing efficiency. Learn key benefits like real-time tracking, reduced downtime, and improved asset management.

More