Can RFID reader modules be integrated with existing ERP systems?

916Learn how to connect RFID reader modules with ERP systems like SAP or Oracle. Explore middleware solutions, API compatibility, and real-time data synchronization.

MoreAll RFID Product

You can set up all the RFID readers and tags you want, but in my experience, the system doesn’t really come alive until you get the EPC right. It’s the brain. The rest is just nerves and muscle.

Electronic Product Code – the name sounds fancy, but it’s basically an ID number for a physical thing. A unique one.

Think of it like this: every item in your warehouse already has a serial number, right? EPC does that, but for everything – from a single screw to a whole shipping container. And it’s global, unlike some messy internal coding system that only your own team can understand. It’s managed by GS1, the same folks who handle barcodes. The 96-bit version is the most common, and honestly, it’s enough for most jobs.

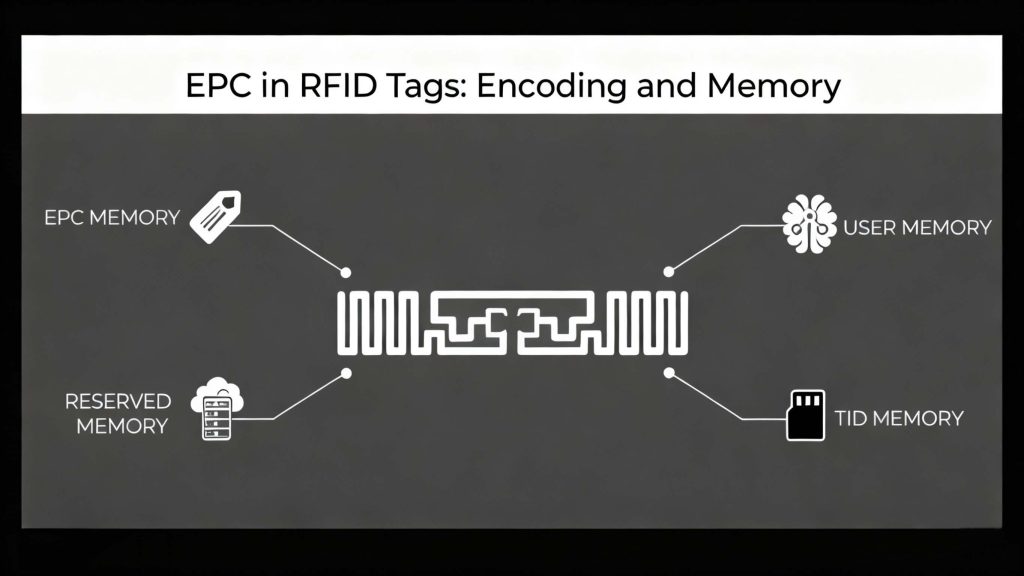

Here’s where people get confused. RFID is the hardware, the tech. EPC is the data on the chip – it’s the soul of the operation.

From what I’ve seen, EPC does two critical things:

I learned this the hard way early on. You can spend a fortune on hardware, but if your EPC design is a mess or doesn’t sync with the backend, the whole project falls apart.

The 96-bit EPC is pretty straightforward. It breaks down into four parts:

You see the logic? It goes from “who made it” to “what it is” to “which exact one it is.” On projects, the worst thing is when a client tries to use some chaotic internal numbering system. It’s a nightmare to maintain and query later.

Forget the textbook version. Here’s how it plays out in the real world, kind of like running a license plate:

Honestly, the weakest link here isn’t the RFID hardware – it’s Step 4, the database. If the data there is old or wrong, the whole system is useless, no matter how fast your readers are. We’ve learned that through plenty of mistakes.

EPC turns RFID from simple identification into actual management. Knowing “something is there” is trivial. Knowing exactly what it is and its entire life story – that’s where the real value is.

We had one client whose biggest win after implementing EPC wasn’t faster inventory (that’s table stakes). It was being able to track every single item through the supply chain. If a customer returned something, they could scan it and know instantly if it was really theirs, when it was made, and where it had been – effectively killing channel diversion and counterfeiting.

At the end of the day, the RFID hardware is just the body. The EPC is the brain that lets objects talk. If you want to do IoT and smart supply chains right, you’d better put some serious thought into how you design and manage your EPCs.

CYKEO Passive RFID Tags are made for wet and high-humidity environments where standard labels do not last. This rfid passive tag is often used around liquids, chemicals and temperature changes, providing stable reading distance and long data life for industrial tracking.

CYKEO CK-BQ1504 Metal RFID Tags is a compact anti-metal UHF RFID solution built for direct mounting on metal surfaces. With stable 8-meter read range, Ucode-8 chip, and long data retention, this rfid metal tag fits tools, containers, automotive parts, and industrial asset tracking.

CYKEO CK-BQ7020 On-Metal RFID Tags are designed for reliable tracking on steel and metal surfaces. Built with an FR4 epoxy body and industrial-grade chips, these On-Metal RFID Tags deliver stable performance, long data life, and chemical resistance, making them a dependable RFID anti-metal tag for harsh environments.

The CYKEO CK-BQ6025 Anti-Metal RFID Tag is built for metal surfaces where standard tags fail. Designed for long-range performance, harsh environments, and stable data retention, this Anti-Metal RFID Tag is ideal for industrial assets, containers, and equipment tracking using on metal RFID tags.

Learn how to connect RFID reader modules with ERP systems like SAP or Oracle. Explore middleware solutions, API compatibility, and real-time data synchronization.

Morehow IoT and RFID are transforming parking management. Find available parking spots in real-time, reserve spaces via mobile app, and reduce traffic congestion with smart parking systems.

MoreDiscover how RFID autoclave solutions improve sterilization tracking, equipment management, and inventory control in hospitals.

MoreLooking for RFID for phones? Learn what smartphones can really do, where they fail, and how CYKEO readers turn phones into RFID tools.

More