RFID Tag Installation: Key Steps for Efficient RFID Identification

748provide detailed analysis from the perspectives of installation preparation, methods, and precautions.

MoreAll RFID Product

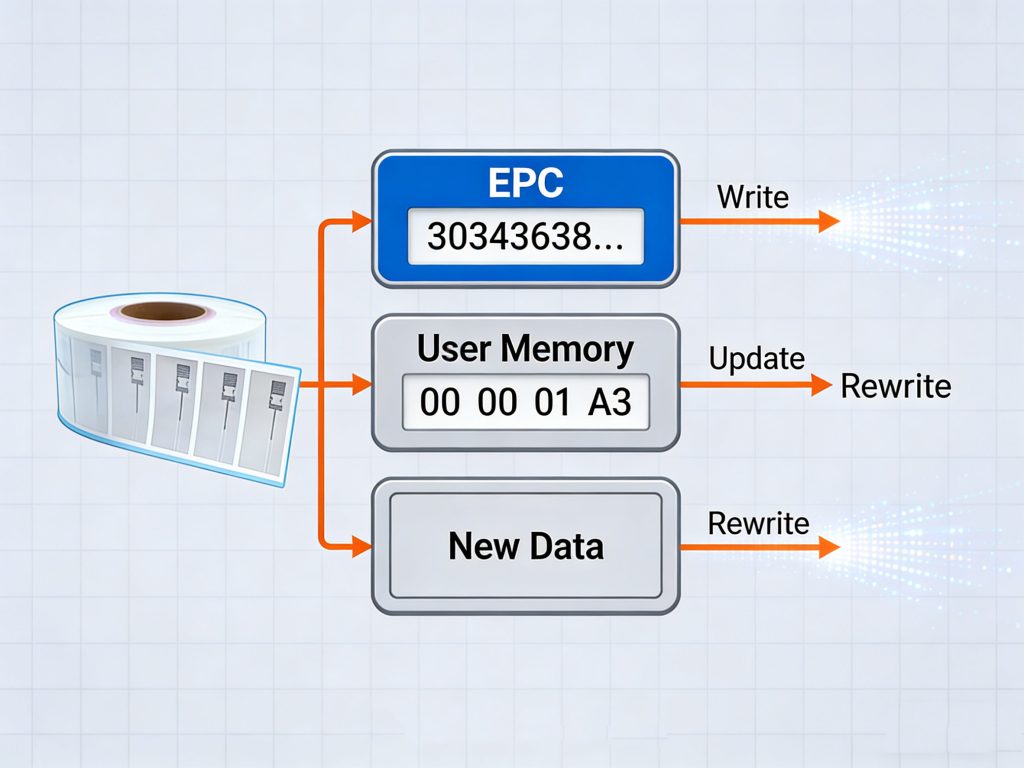

When you’re actually building RFID systems—not just demoing them—you quickly realize that whether a tag is rewritable or not has a much bigger impact than most people expect. For RFID software solution providers and RFID developers, rewritable RFID tags aren’t a “nice-to-have.” They directly affect how flexible your system can be over time.

I’ve seen projects where everything worked fine at launch. Tags were readable, data flowed, the client was happy. Then a few months later, requirements changed—status updates, process flags, lifecycle tracking. That’s when the problem showed up: the tags couldn’t be rewritten. At that point, no amount of backend logic could fix the limitation at the tag level.

Rewritable RFID tags give your software room to breathe

From a software perspective, the real value of rewritable RFID tags isn’t the hardware itself—it’s data lifecycle control.

In real-world systems, tag data is rarely static. We regularly need to update:

When tags support multiple write cycles, your software design becomes cleaner and far more resilient. That’s why many solution providers start tag selection by reviewing a full RFID tag product range and filtering for chips that support rewritable memory, appropriate user memory size, and stable reader compatibility—before locking down the data model.

This is one of the most common misunderstandings I see, especially early in projects.

Many people assume “RFID equals editable data.” In reality, some RFID tags are designed as one-time programmable (OTP). Once written and locked, the data cannot be changed. That may be fine for simple ID applications, but it becomes a hard limitation in dynamic systems.

If you want a clear technical breakdown of this, the article Can all RFID tags be rewritten or reprogrammed? explains the differences very well. It’s the kind of resource I often share internally or with clients to align expectations before development starts.

Based on real project experience, here are a few scenarios where rewritable RFID tags are practically mandatory.

1. Asset management platforms

Assets change state over time. If tag data can’t evolve with the asset, your system ends up relying entirely on the database, and the RFID tag becomes little more than a static ID.

2. Manufacturing process tracking

In production environments, tags often pass through multiple stations, each writing process data. This workflow breaks down immediately if the tag can’t be rewritten reliably.

3. Reusable logistics containers and pallets

For returnable assets, being able to clear and rewrite tag data is critical. Otherwise, tag reuse becomes risky and operationally expensive.

If you’re designing RFID software or system architecture, my honest recommendation is this:

decide on rewritable tag capability at the very beginning of the project.

Especially when:

In these cases, selecting suitable tags from a proven RFID tag portfolio first—and then designing your data structure around those capabilities—will save you from painful redesigns later.

For RFID developers, rewritable RFID tags aren’t just a hardware decision. They define how much freedom your software will have in the future.

If the tag is locked, your system is locked.

Choosing correctly at the start gives your solution room to grow—without rewriting everything later.

When you’re actually building RFID systems—not just demoing them—you quickly realize that whether a tag is rewritable or not has a much bigger impact than most people expect. For RFID software solution providers and RFID developers, rewritable RFID tags aren’t a “nice-to-have.” They directly affect how flexible your system can be over time.

I’ve seen projects where everything worked fine at launch. Tags were readable, data flowed, the client was happy. Then a few months later, requirements changed—status updates, process flags, lifecycle tracking. That’s when the problem showed up: the tags couldn’t be rewritten. At that point, no amount of backend logic could fix the limitation at the tag level.

From a software perspective, the real value of rewritable RFID tags isn’t the hardware itself—it’s data lifecycle control.

In real-world systems, tag data is rarely static. We regularly need to update:

When tags support multiple write cycles, your software design becomes cleaner and far more resilient. That’s why many solution providers start tag selection by reviewing a full RFID tag product range and filtering for chips that support rewritable memory, appropriate user memory size, and stable reader compatibility—before locking down the data model.

This is one of the most common misunderstandings I see, especially early in projects.

Many people assume “RFID equals editable data.” In reality, some RFID tags are designed as one-time programmable (OTP). Once written and locked, the data cannot be changed. That may be fine for simple ID applications, but it becomes a hard limitation in dynamic systems.

If you want a clear technical breakdown of this, the article Can all RFID tags be rewritten or reprogrammed? explains the differences very well. It’s the kind of resource I often share internally or with clients to align expectations before development starts.

Based on real project experience, here are a few scenarios where rewritable RFID tags are practically mandatory.

1. Asset management platforms

Assets change state over time. If tag data can’t evolve with the asset, your system ends up relying entirely on the database, and the RFID tag becomes little more than a static ID.

2. Manufacturing process tracking

In production environments, tags often pass through multiple stations, each writing process data. This workflow breaks down immediately if the tag can’t be rewritten reliably.

3. Reusable logistics containers and pallets

For returnable assets, being able to clear and rewrite tag data is critical. Otherwise, tag reuse becomes risky and operationally expensive.

If you’re designing RFID software or system architecture, my honest recommendation is this:

decide on rewritable tag capability at the very beginning of the project.

Especially when:

In these cases, selecting suitable tags from a proven RFID tag portfolio first—and then designing your data structure around those capabilities—will save you from painful redesigns later.

For RFID developers, rewritable RFID tags aren’t just a hardware decision. They define how much freedom your software will have in the future.

If the tag is locked, your system is locked.

Choosing correctly at the start gives your solution room to grow—without rewriting everything later.

provide detailed analysis from the perspectives of installation preparation, methods, and precautions.

MoreThe global warehousing and logistics industry is rapidly developing, and traditional warehouse management methods are gradually struggling to meet enterprises’ demands for efficient and accurate operations.

MoreConfused between UHF and HF RFID antennas? Learn the pros, cons, and ideal applications for each frequency band to optimize your system’s performance.

MoreWhere to buy RFID tags without wasting budget? Learn where professionals source reliable RFID tags and what to avoid before ordering.

More