How to Choose the Best Handheld RFID Scanner for Your Business

583Discover the key factors to consider when selecting a handheld RFID scanner for your business, from durability to software compatibility. Make an informed choice.

MoreAll RFID Product

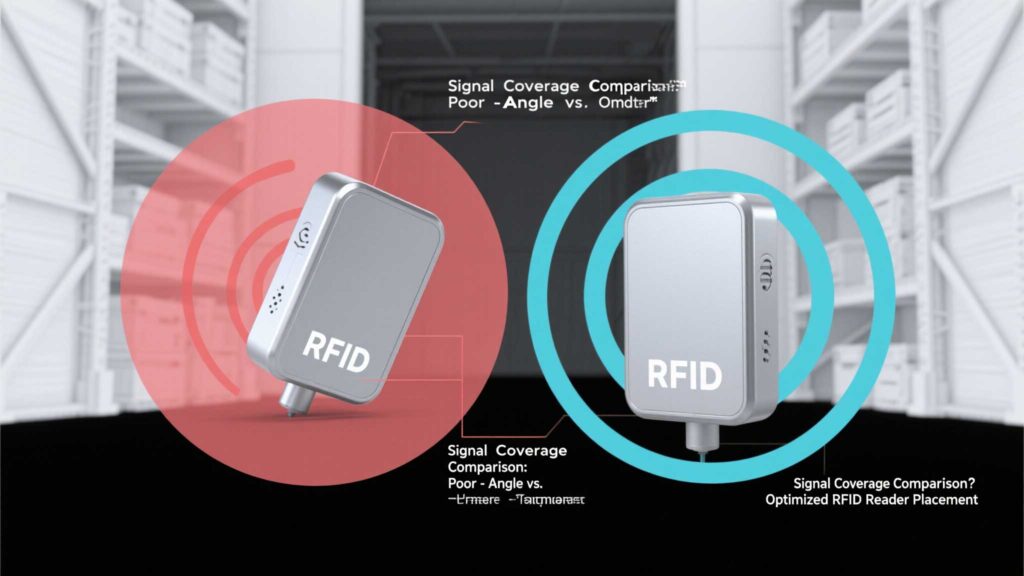

You installed RFID Module readers, but half your inventory scans fail. Tags on top shelves ghost-read, while items near the floor go unnoticed. The issue isn’t your gear—it’s placement. Like positioning speakers in a concert hall, RFID reader modules need strategic placement to avoid dead zones and chaos. Here’s how to tweak their position, angle, and settings to turn spotty scans into flawless coverage.

a. Height Matters More Than You Think

b. Angle for Signal Spread, Not Straight Shots

c. Distance ≠ Power

Case Study: A Cykeo client boosted read rates by 73% simply remounting readers from walls to ceilings.

a. Metal Surfaces

b. Liquid Obstacles

c. Electrical Noise

a. Choke Points First

b. Dead Zone Patrol

c. Dynamic Adjustments

a. Adjust Read Cycles

b. Filter False Positives

c. Sync Multiple Readers

a. RFID Signal Mapper Apps

b. Tag Clusters

c. Crowdsourced Data

If DIY hacks fail:

Takeaway: Optimizing RFID reader placement isn’t about buying better gear—it’s about working smarter. Test heights, dodge interference, and let software fill the gaps. Even a 20% improvement cuts manual errors, speeds audits, and saves hours monthly. Start with one problem zone, perfect it, then scale. Because in RFID, inches and degrees decide success or chaos.

Discover the key factors to consider when selecting a handheld RFID scanner for your business, from durability to software compatibility. Make an informed choice.

Morelong-range industrial RFID readers for warehouse, production line, and logistics operations.integration with RFID antennas,Custom RFID hardware solution providers.

MoreWhich industries benefit most from RFID reader technology? Explore healthcare, retail, logistics, and more—plus how Cykeo drives efficiency and accuracy.

MoreDiscover how RFID cabinet pharmacy storage systems improve medication security, real-time inventory tracking, and regulatory compliance. Learn how smart RFID pharmacy cabinets streamline operations and reduce audit risks.

More