Can Android Read RFID?

66Wondering if you can skip buying a scanner? We explain if Android can read RFID, what actually works, and why it won't replace professional RFID systems.

MoreAll RFID Product

For RFID solution providers, long range RFID is no longer just a “nice-to-have” feature. In real projects—warehouses, factories, yards, gated facilities, or industrial asset tracking—it often becomes the backbone of automation efficiency. The challenge isn’t whether long range RFID works, but how to make it work reliably in the field.

This article pulls together hands-on experience, performance fundamentals, and industrial selection logic, while referencing proven resources and products that solution providers can directly use in system design.

In practice, long range RFID usually refers to UHF RFID systems operating in the 860–960 MHz band, where reading distances can reach 10–20 meters or more, depending on configuration and environment.

But distance alone doesn’t define success. As discussed in Long Range RFID Reader: Hands-On Experience and Tips, many early-stage projects fail not because of the reader itself, but because of underestimated factors like antenna orientation, tag polarization, and surrounding materials.

For solution providers, “long range” should be interpreted as:

Many engineers start by testing long range RFID using modules or development boards. This phase is useful—but limited.

According to the hands-on insights shared in Long Range RFID Reader: Hands-On Experience and Tips, typical issues during early testing include:

These problems usually trace back to antenna gain, matching, and placement, rather than the RF chip itself.

Once projects move toward production, solution providers generally shift to industrial-grade long range RFID readers, where enclosure design, RF shielding, and interface stability matter just as much as raw RF power.

Before finalizing system architecture, it’s critical to understand what truly affects read performance. RFID Reader Performance breaks this down clearly.

Key influencing factors include:

Higher RF power helps, but compliance with regional regulations (FCC, CE, etc.) defines the real ceiling.

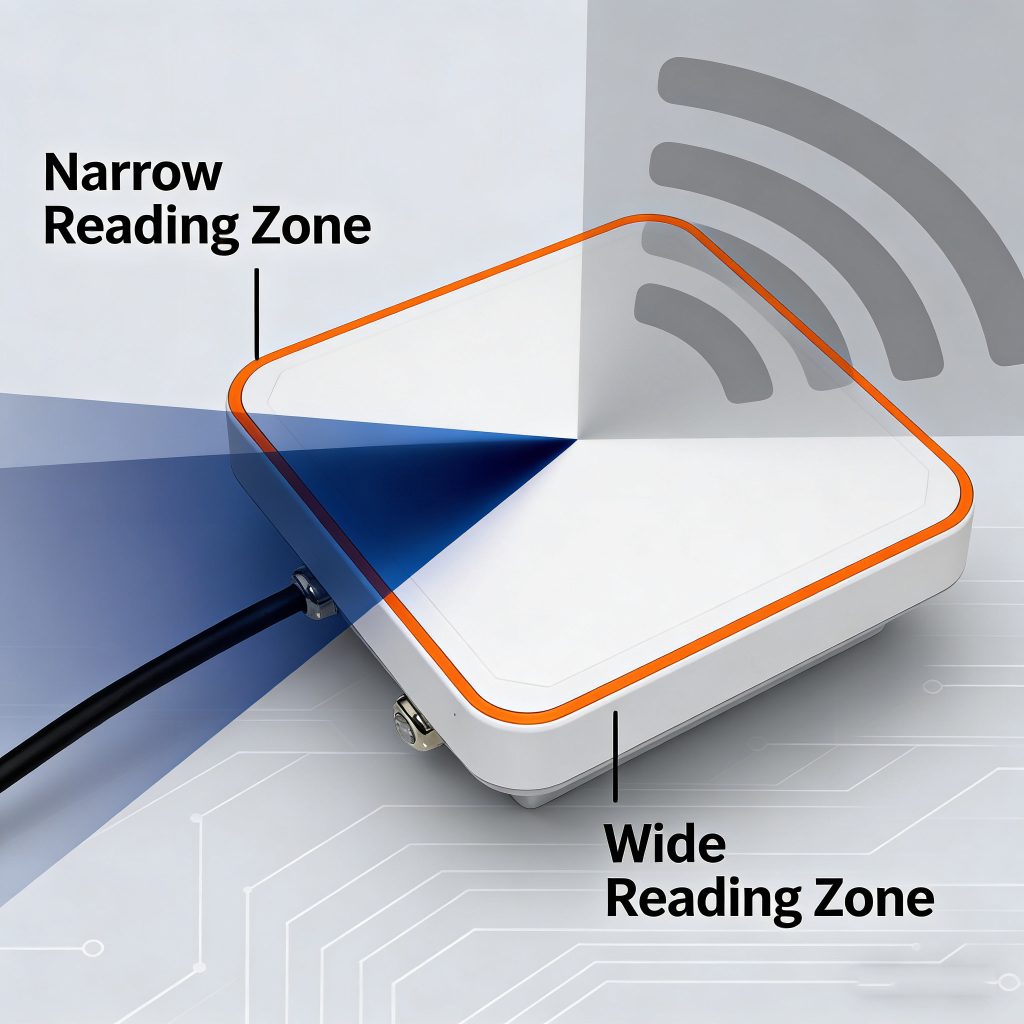

A 12 dBi directional antenna can dramatically extend distance—but at the cost of coverage width. This tradeoff must match the application layout.

Even high-quality UHF tags behave very differently depending on mounting surface, orientation, and polarization alignment.

Metal structures, liquid materials, reflections, and other RF devices often matter more than datasheet specs.

For solution providers, these variables should be evaluated together—not in isolation.

When systems scale up, reader selection becomes strategic. What Are the Best Long Range RFID Readers for Industrial Asset Tracking outlines why industrial deployments demand more than basic read distance.

Read range and multi-tag throughput

Industrial UHF readers must handle dense tag populations without collision issues.

Mechanical durability and protection level

IP-rated enclosures and vibration resistance are essential for factories, docks, and outdoor sites.

System integration capability

Ethernet, PoE, REST APIs, SDK support, and compatibility with WMS, MES, or ERP systems directly affect project delivery speed.

Long-term stability and maintainability

Downtime costs money. Reliable firmware and remote management support are not optional.

For solution providers preparing proposals or system documentation, it’s useful to reference concrete hardware options.

The Long Range RFID Reader product series offers multiple antenna gain configurations (4 dBi, 6 dBi, 9 dBi, 12 dBi), making it easier to match readers to different layouts such as:

Linking product specifications directly within solution documentation also helps align technical design with procurement expectations.

Based on real deployment experience and the referenced materials:

These steps reduce redesign cycles and improve client satisfaction.

For RFID solution providers, long range RFID is less about pushing distance limits and more about engineering predictable, stable systems. By understanding performance fundamentals, choosing industrial-grade readers, and aligning hardware with system architecture, long range RFID becomes a reliable tool rather than a deployment risk.

For RFID solution providers, long range RFID is no longer just a “nice-to-have” feature. In real projects—warehouses, factories, yards, gated facilities, or industrial asset tracking—it often becomes the backbone of automation efficiency. The challenge isn’t whether long range RFID works, but how to make it work reliably in the field.

This article pulls together hands-on experience, performance fundamentals, and industrial selection logic, while referencing proven resources and products that solution providers can directly use in system design.

In practice, long range RFID usually refers to UHF RFID systems operating in the 860–960 MHz band, where reading distances can reach 10–20 meters or more, depending on configuration and environment.

But distance alone doesn’t define success. As discussed in Long Range RFID Reader: Hands-On Experience and Tips, many early-stage projects fail not because of the reader itself, but because of underestimated factors like antenna orientation, tag polarization, and surrounding materials.

For solution providers, “long range” should be interpreted as:

Many engineers start by testing long range RFID using modules or development boards. This phase is useful—but limited.

According to the hands-on insights shared in Long Range RFID Reader: Hands-On Experience and Tips, typical issues during early testing include:

These problems usually trace back to antenna gain, matching, and placement, rather than the RF chip itself.

Once projects move toward production, solution providers generally shift to industrial-grade long range RFID readers, where enclosure design, RF shielding, and interface stability matter just as much as raw RF power.

Before finalizing system architecture, it’s critical to understand what truly affects read performance. RFID Reader Performance breaks this down clearly.

Key influencing factors include:

Higher RF power helps, but compliance with regional regulations (FCC, CE, etc.) defines the real ceiling.

A 12 dBi directional antenna can dramatically extend distance—but at the cost of coverage width. This tradeoff must match the application layout.

Even high-quality UHF tags behave very differently depending on mounting surface, orientation, and polarization alignment.

Metal structures, liquid materials, reflections, and other RF devices often matter more than datasheet specs.

For solution providers, these variables should be evaluated together—not in isolation.

When systems scale up, reader selection becomes strategic. What Are the Best Long Range RFID Readers for Industrial Asset Tracking outlines why industrial deployments demand more than basic read distance.

Read range and multi-tag throughput

Industrial UHF readers must handle dense tag populations without collision issues.

Mechanical durability and protection level

IP-rated enclosures and vibration resistance are essential for factories, docks, and outdoor sites.

System integration capability

Ethernet, PoE, REST APIs, SDK support, and compatibility with WMS, MES, or ERP systems directly affect project delivery speed.

✔ Long-term stability and maintainability

Downtime costs money. Reliable firmware and remote management support are not optional.

For solution providers preparing proposals or system documentation, it’s useful to reference concrete hardware options.

The Long Range RFID Reader product series offers multiple antenna gain configurations (4 dBi, 6 dBi, 9 dBi, 12 dBi), making it easier to match readers to different layouts such as:

Linking product specifications directly within solution documentation also helps align technical design with procurement expectations.

Based on real deployment experience and the referenced materials:

These steps reduce redesign cycles and improve client satisfaction.

For RFID solution providers, long range RFID is less about pushing distance limits and more about engineering predictable, stable systems. By understanding performance fundamentals, choosing industrial-grade readers, and aligning hardware with system architecture, long range RFID becomes a reliable tool rather than a deployment risk.

Wondering if you can skip buying a scanner? We explain if Android can read RFID, what actually works, and why it won't replace professional RFID systems.

MoreHow to read an RFID tag in real scenarios. Learn what equipment you need, common mistakes, and how CYKEO readers make RFID work reliably.

MoreWant to learn how to make an RFID reader? We break down the real engineering choices: build a simple HF cloner, integrate a UHF module, or embark on a multi-year RF design journey.

MoreThe customer raised the problems and requirements for RFID Gate Reader products. We listen to the customer's answers about the environment in which the product is used. Give each other all opinions to each other about the project si...

More