How to Read RFID Tags

134Need to know how to read RFID tags? Follow this practical guide covering tag types, reader selection, and setup steps for a working RFID system.

MoreAll RFID Product

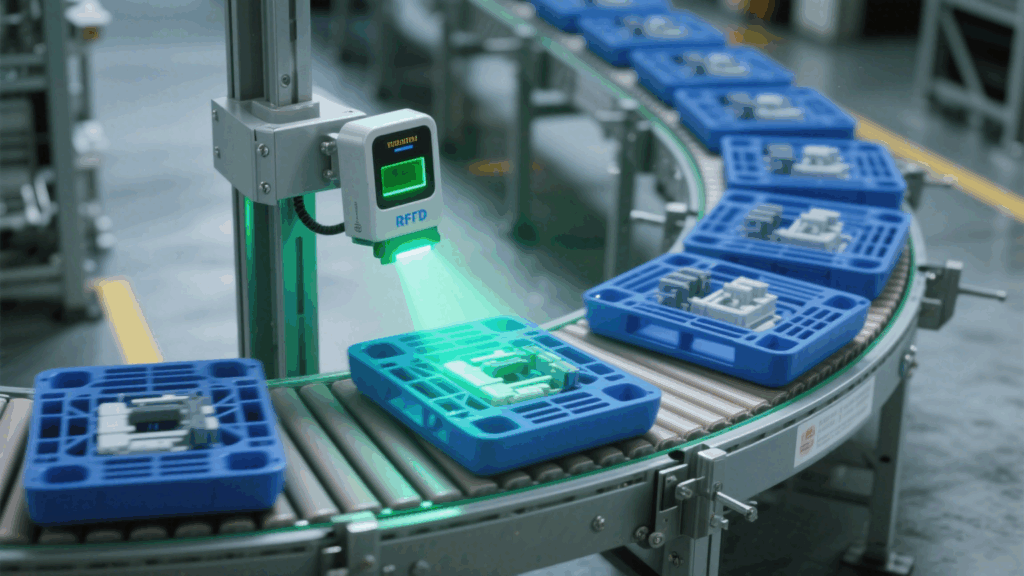

Industrial RFID Reader is radio frequency identification device designed specifically for harsh industrial conditions. It operates reliably in high temperatures, humid or dusty areas, and environments with strong electromagnetic interference. Unlike commercial-grade RFID readers, industrial RFID readers support stable and efficient data reading and writing over long periods. These devices are widely used in automated production lines, smart warehouses, and asset management systems.

High-performance Industrial RFID Reader offers the following capabilities:

Industrial RFID Readers are widely used in the following scenarios:

To choose the right Industrial RFID Reader, consider these factors:

With the rise of Industry 4.0 and IoT, Industrial RFID Readers continue to evolve in the following directions:

Industrial RFID Readers play vital role in industrial IoT by transforming traditional factory operations. Deploying high-performance RFID readers helps manufacturers achieve real-time visibility and intelligent management across production, warehousing, and logistics. This boosts both operational efficiency and accuracy, making RFID foundational technology for the future of smart manufacturing.

Cykeo’s RFID Smart Tool Cabinet enables 10-second tool audits, user access control & real-time alerts for construction/oil/gas. Features 21.5″ touchscreen, IP54 steel body & -30°C~60°C operation. Supports SAP/Oracle integration.

Cykeo’s Intelligent Weighing Tool Cabinet combines weight sensors & RFID for 100% tool accountability. Features solar/4G options, IP54 steel-glass body & nuclear/rail compliance. Supports SAP/Oracle integration.

Cykeo’s solar-powered RFID Inventory Tool Cabinet enables 5-second audits for remote sites. Features 160W solar, Android 7.1, 4G & extreme temp operation for oil/energy/mining sectors.

Cykeo’s industrial RFID Tool Cart features 14″ touchscreen, 400+ tool scanning, and carbon steel construction for aviation MRO, power plants and construction sites. 5-second inventory scans.

Need to know how to read RFID tags? Follow this practical guide covering tag types, reader selection, and setup steps for a working RFID system.

MoreDiscover why the RFID 13.56 MHz reader is the best choice for modern access control and industrial tracking. Real-world insights, practical tips, and lessons learned from hands-on installations.

MoreRFID device used in hot mix workability gyratory testing helps track samples and compaction data. Learn how it’s applied in real asphalt labs.

MoreNeed RFID readers that survive factory floors? We compare heat-resistant, high-speed UHF readers for automotive lines—no marketing fluff.

More