RFID Asset Tracking Cost Explained: What You Must Know Before Investing

910Explore RFID asset tracking costs with Cykeo's expert guide—breakdown of tag, reader, and software pricing for efficient asset management.

MoreAll RFID Product

Keeping track of assets in an industrial setting is rarely simple. Tools, equipment, and materials are constantly exposed to tough conditions—right next to furnaces, on dusty construction sites, in humid warehouses, or around corrosive chemicals. Ordinary RFID tags just don’t hold up. A few hours near heat or a splash of water, and they can fail completely.

This is where Rugged RFID tags make a real difference. Built with strong casings and durable materials, they quietly do their job, keeping track of assets no matter what’s happening around them.

I remember visiting a mid-sized factory in New York. Their tool tracking system had been failing for two months with regular tags. Once they switched to high-temperature, impact-resistant tags, the failures almost stopped entirely. Watching that turnaround in action really made me appreciate how much tag durability matters in real-life operations.

High-Temperature Resistance

In factories that work with steel or glass, surfaces can easily reach over 80°C. Normal tags fail in hours. Rugged tags, on the other hand, can handle temperatures from -40°C to +85°C—or sometimes even higher—so tracking never stops.

Impact Resistance

Industrial sites are full of bumps, knocks, and drops. Tools fall, carts collide, packages shift around. A rugged tag can take the hit and still work. On construction sites, in warehouses, or along production lines, that kind of toughness is priceless.

Waterproof and Dustproof

Humidity, rain, mud, and dust are everyday problems. IP68-rated tags can survive submerged under a meter of water and keep dust out, keeping your data safe. I once saw a tag pulled from a pond at a water treatment facility in California—it still scanned perfectly. Small but incredibly tough.

Chemical Resistance

Corrosive chemicals, acids, and vapors are common in many industrial environments. Rugged tags are sealed to withstand this kind of exposure, remaining functional even after months. That reliability is vital for maintenance and safety checks.

Manufacturing

Tracking tools and components in real time keeps production moving smoothly. I’ve seen lines where standard tags failed, causing confusion and slowing down deliveries. Rugged tags fixed that problem quickly.

Logistics and Warehousing

Inventory mistakes are all too common. Rugged tags handle bumps, moisture, and dust, letting you track items accurately and avoid counting errors.

Construction

Tools, scaffolding, and small machines get dropped, banged around, and covered in dust constantly. Durable tags make sure everything is easy to find, cutting down on losses and delays.

Energy Sector

In oil fields and wind farms, accurate tracking is critical. Rugged tags make sure inspections reflect the real condition of equipment, helping prevent accidents and operational slowdowns.

Choosing the right Rugged RFID tag isn’t about picking the most expensive one. It’s about matching the tag to your actual environment:

Practical Advice: Put tags where they won’t be blocked, make sure readers are compatible with the tags, and check them regularly. One missed inspection in a harsh environment can halt an entire production line.

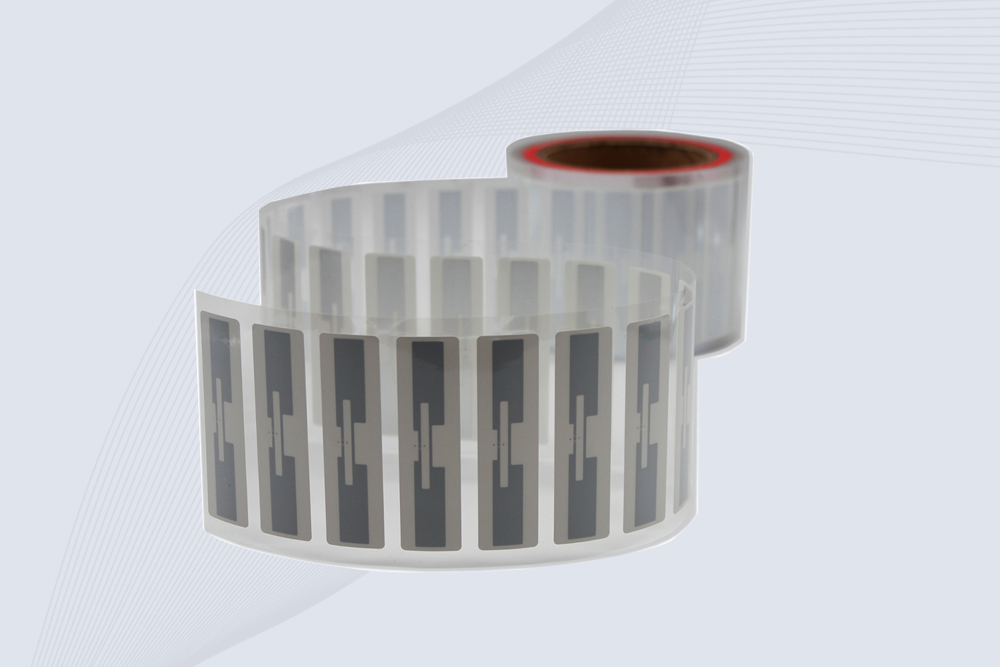

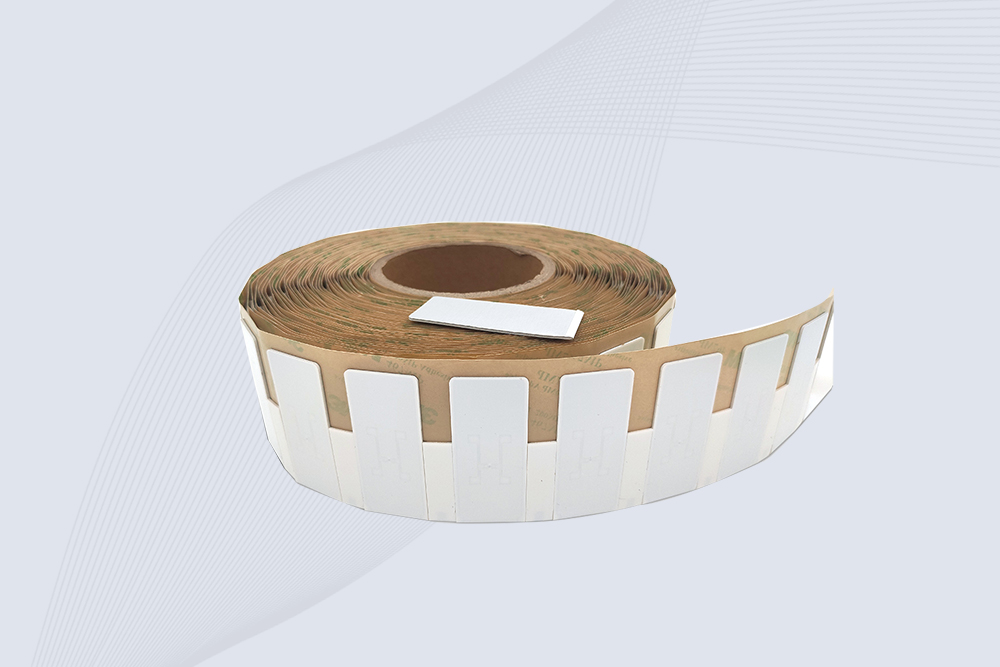

CYKEO Passive RFID Tags are made for wet and high-humidity environments where standard labels do not last. This rfid passive tag is often used around liquids, chemicals and temperature changes, providing stable reading distance and long data life for industrial tracking.

CYKEO CK-BQ1504 Metal RFID Tags is a compact anti-metal UHF RFID solution built for direct mounting on metal surfaces. With stable 8-meter read range, Ucode-8 chip, and long data retention, this rfid metal tag fits tools, containers, automotive parts, and industrial asset tracking.

CYKEO CK-BQ7020 On-Metal RFID Tags are designed for reliable tracking on steel and metal surfaces. Built with an FR4 epoxy body and industrial-grade chips, these On-Metal RFID Tags deliver stable performance, long data life, and chemical resistance, making them a dependable RFID anti-metal tag for harsh environments.

The CYKEO CK-BQ6025 Anti-Metal RFID Tag is built for metal surfaces where standard tags fail. Designed for long-range performance, harsh environments, and stable data retention, this Anti-Metal RFID Tag is ideal for industrial assets, containers, and equipment tracking using on metal RFID tags.

Explore RFID asset tracking costs with Cykeo's expert guide—breakdown of tag, reader, and software pricing for efficient asset management.

MoreDoes aluminum foil stop RFID signals? Learn what really happens, when it works, when it fails, and how RFID behaves around metal in real use.

MoreExplore how NFC phones can be used as RFID tags for efficient asset management and tracking. Learn the differences between NFC and RFID technologies, and discover the benefits of combining both in real-world applications. Check out our guide and e...

MoreIn today's fast-paced society, innovative shopping models such as unmanned stores and self-checkout systems are increasingly popular with consumers. At the heart of these innovations lies a key technology: Radio Frequency Identification (RF...

More