Antennas rfid uhf in the IoT era

652Antennas rfid uhf play irreplaceable role in many fields with their outstanding performance.

MoreAll RFID Product

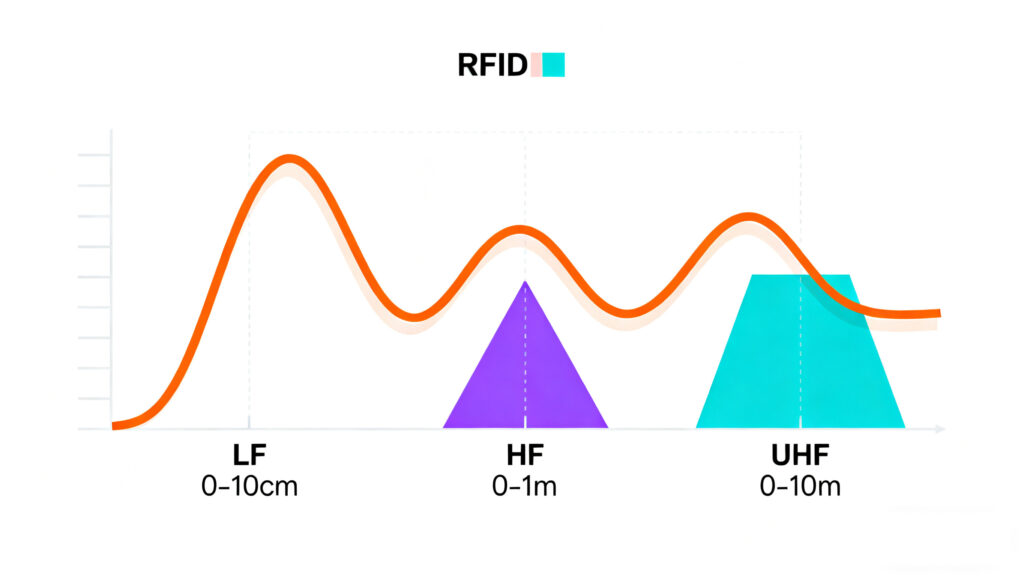

When people first step into RFID projects — whether it’s access control, warehouse tracking, or industrial automation — one of the most confusing parts is figuring out what kind of RFID frequency detector they actually need. It’s easy to assume that “RFID is RFID,” but in reality, the technology spans across several frequency bands, each with different communication methods, reading distances, and equipment requirements.

RFID systems don’t all speak the same “language.”

Some work at low frequency (around 125 kHz), some at high frequency (13.56 MHz), and others at ultra-high frequency (860–960 MHz). If you’re trying to detect or read a tag, you need a detector that matches not only the frequency but also the protocol behind it — such as ISO 14443, ISO 15693, or EPC Gen2.

That’s why a random reader won’t pick up every tag. You might know the frequency, but if your detector doesn’t understand the modulation or data standard, it won’t respond. Frequency is only the first piece of the puzzle.

Depending on what you’re trying to find out, there are a few practical tools people use in the field:

Each of these serves a different goal — quick detection, continuous monitoring, or deep signal analysis. There’s no “one detector fits all” here.

When you’re choosing between handheld and fixed detectors, think about your environment and workflow.

If your team is constantly moving, doing spot checks or asset tracking across different areas, handheld units make sense. They’re easy to carry and don’t require installation.

But if your process involves conveyor belts, automated gates, or a production line where tags move past a specific point, fixed detectors are better. They can run non-stop, handle hundreds of reads per second, and feed data directly into your system.

The trade-off? Handhelds are cheaper and flexible, but their range and stability are limited. Fixed detectors are powerful but more expensive and less adaptable once installed.

People often ask: “If I just know the frequency, can I detect any RFID tag?”

In short — not really.

You might detect a presence or signal on that frequency, but without protocol compatibility and the right antenna setup, you won’t get meaningful data. It’s like tuning into a radio station — even if you land on the right channel, you still need the right radio to decode the broadcast.

Another practical point: physical environment matters. Metal surfaces, liquid containers, and even humidity can affect how well RFID signals propagate. So before you blame your detector, check the surroundings too.

If you’re experimenting, start simple. Try identifying what frequency range your tags operate on first — LF, HF, or UHF. Once that’s clear, choose a detector that matches it.

For professionals working on industrial or logistics systems, invest in fixed detectors that can integrate into your control network.

At the end of the day, RFID frequency detection isn’t just about hardware — it’s about understanding how the signal behaves in your specific use case. The more you work hands-on with different tags and environments, the more natural it becomes to pick the right tool for the job.

Cykeo CYKEO-B9 UHF Bluetooth handheld RFID scanner features 12m UHF range, 200+ tags/sec scanning, IP67 rugged design for retail/warehouse/pharma. Supports Android SDK & real-time Bluetooth 5.0 transmission.

Cykeo CYKEO-B4 UHF Handheld RFID Reader scanner delivers 1300 tags/sec reading, 30m UHF range, and 12-hour battery life. IP65 rugged design with barcode/NFC/ID scanning for retail/manufacturing/logistics.

Cykeo CYKEO-B2 industrial UHF RFID handheld offers 10m range, 500 tags/sec scanning, Android 11 OS, and IP65 rugged design for retail/warehouse/manufacturing.

Cykeo CYKEO-B3 industrial RFID Reader Handheld, terminal offers 2m read range, multi-protocol scanning (NFC/barcode/ID), Android 10 OS, and IP65 ruggedness for logistics/retail/manufacturing.

Antennas rfid uhf play irreplaceable role in many fields with their outstanding performance.

MoreDiscover the key factors to consider when selecting a handheld RFID scanner for your business, from durability to software compatibility. Make an informed choice.

MoreCan NFC replace RFID? Learn where NFC works as RFID, key limitations, and real-world applications where each technology shines.

MoreLearn how iPhones and Android devices can emulate RFID tags using NFC or third-party tools. Discover Cykeo’s mobile-compatible RFID readers for seamless integration.

More