How to Make a RFID Reader Module

The question how to make a RFID reader module pops up in maker forums and engineering labs alike. While you can buy a pre-built module for a few dollars, building one from the IC up is a fantastic way to deeply understand the RF (radio-frequency) fundamentals. Let’s be clear: it’s not a single-evening Arduino shield project. It involves careful circuit design, PCB layout, and antenna tuning. Here’s a realistic breakdown of what it takes.

Step 1: The Critical Choice – Picking Your Frequency

You don’t just start soldering. The first and most important decision is frequency: 125 kHz (LF), 13.56 MHz (HF/NFC), or 860-960 MHz (UHF). For a first-time diy rfid reader project, 13.56 MHz is the most accessible. The chips are common, and the antenna is a manageable size. We’ll focus on that. The popular MFRC522 chip from NXP is the go-to for this. Get its 100+ page datasheet—that’s your bible now.

Step 2: Gathering the Core Components & Designing the Circuit

Your RFID module needs more than just the RFID IC. You’ll need:

- The Brains: The MFRC522 or similar IC (e.g., PN532 for more features).

- The Crystal: A precise 13.56 MHz quartz crystal oscillator for the carrier wave.

- The Matching Network: This is the heart of your rfid antenna design and tuning. It’s a set of capacitors and resistors between the chip’s antenna pins and the actual antenna coil. Their values are calculated from the chip’s datasheet and are critical for efficiency.

- The Antenna Coil: This is a hand-wound or pre-made copper coil. Its inductance (usually 1-3 µH) must precisely resonate at 13.56 MHz with your matching network. Getting this wrong is the #1 reason for a dead RFID reader.

- The PCB: This is where most homemade modules fail. The antenna loop and its matching network traces must be designed as a controlled impedance circuit. They should be symmetrical, away from ground planes, and on a good-quality FR4 board. Don’t try this on a breadboard.

Step 3: The Build – Soldering and Assembly

Soldering and assembling the rfid reader board requires a steady hand and fine-pitch soldering skills. The MFRC522 is a QFN package—its pins are underneath. You’ll likely need a hot-air rework station. Use plenty of flux. Solder the crystal and matching network components as close to the chip as physically possible. Any extra wire length here introduces parasitic inductance and kills performance.

Step 4: The Make-or-Break Phase: Antenna Tuning

Once assembled, you must tune the antenna. You’ll need an oscilloscope and a Vector Network Analyzer (VNA) is ideal. You’re checking if the antenna circuit resonates sharply at 13.56 MHz. You adjust the matching capacitor values (often using variable caps during tuning) to get the deepest dip at the right frequency on your scope or VNA. This is not optional. An untuned antenna gives you a read range of millimeters, if it works at all.

Step 5: Programming and Testing

With a hopefully functional hardware, you now write firmware. The chip communicates via SPI or I2C with a microcontroller (like an Arduino). Your code must initialize the chip, manage the anti-collision protocol, and read the tag’s UID. This is where troubleshooting rfid reader communication issues begins. Use a logic analyzer on the SPI bus. Is the chip responding to commands? Is the RFID tags responding? Is the signal clean?

The Hard Truth and a Practical Alternative

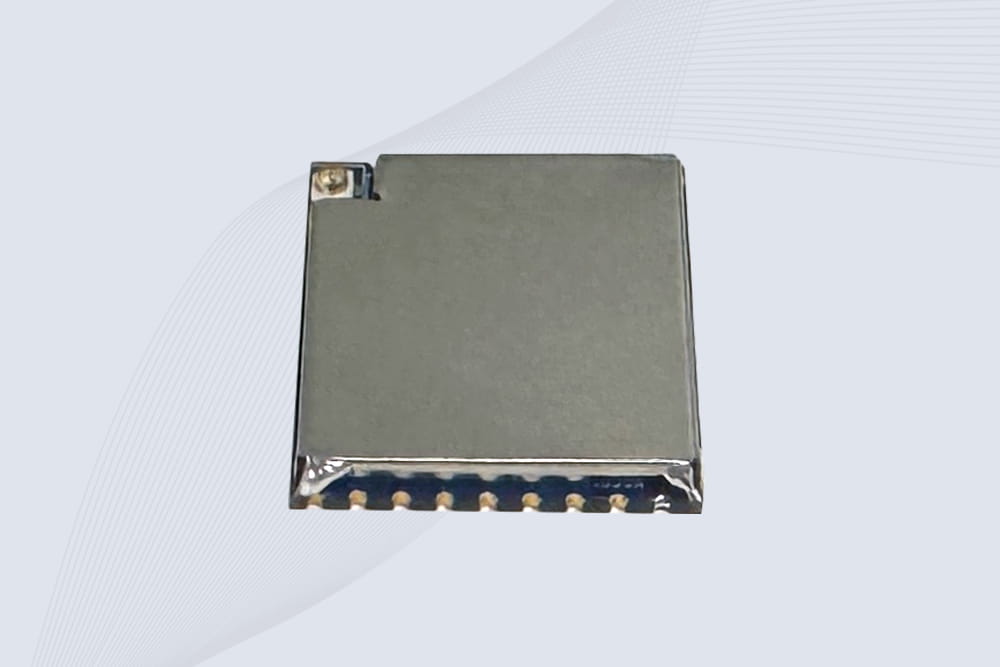

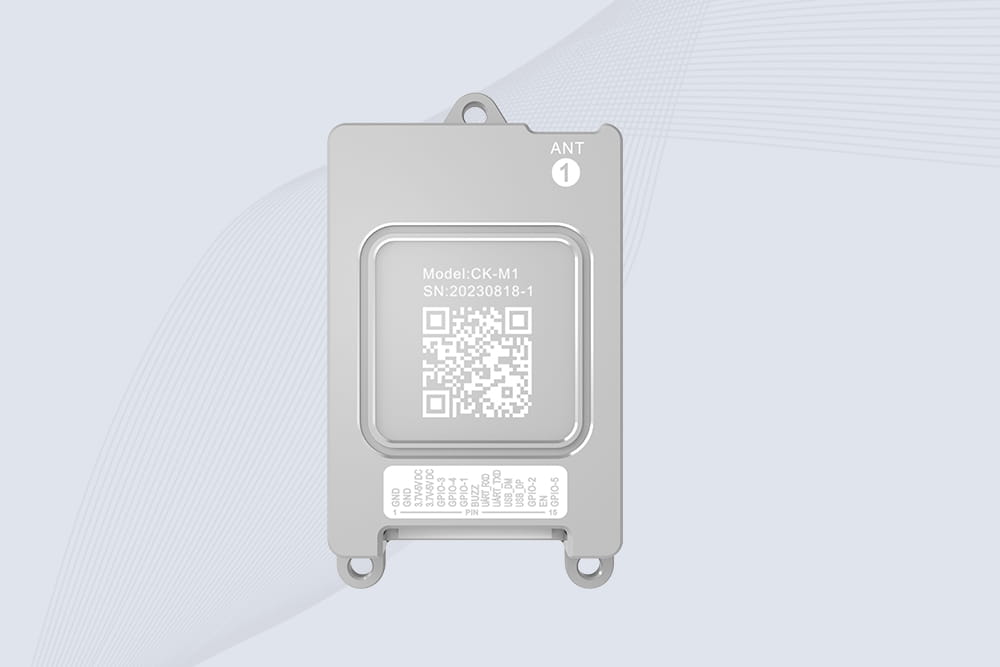

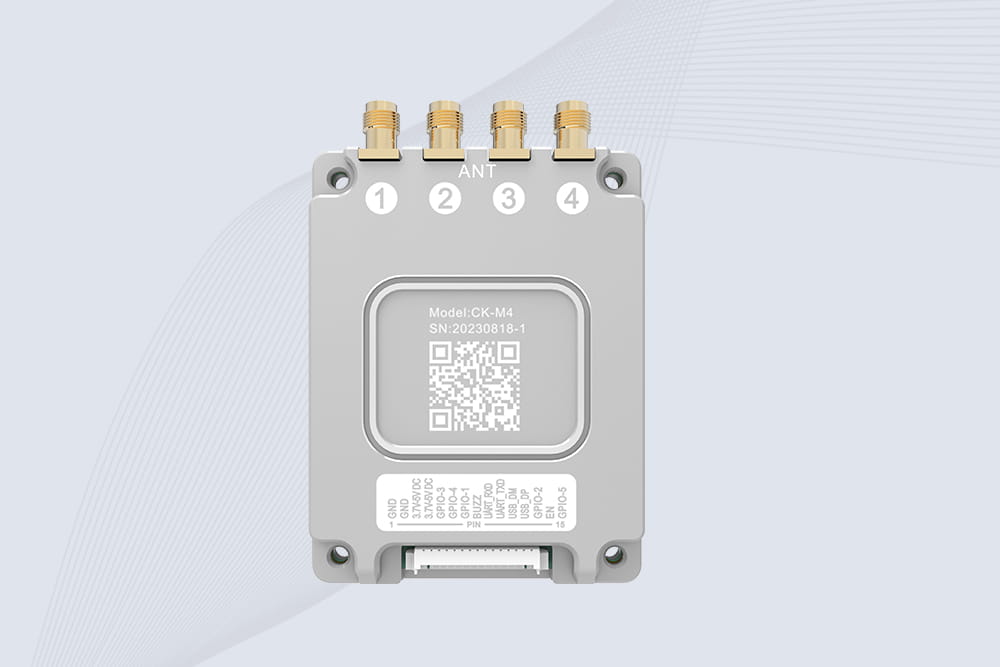

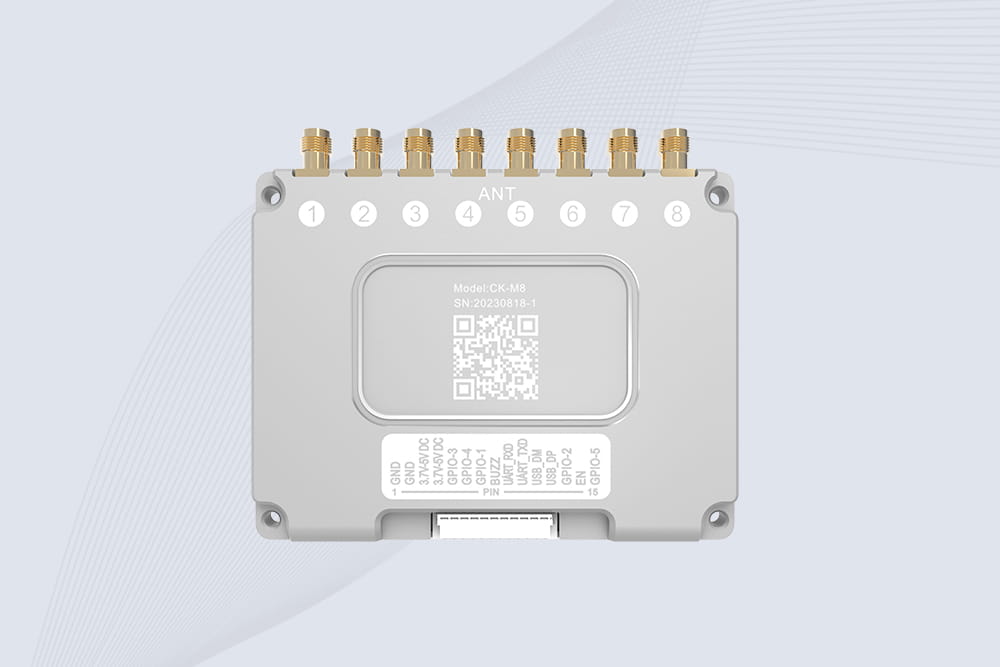

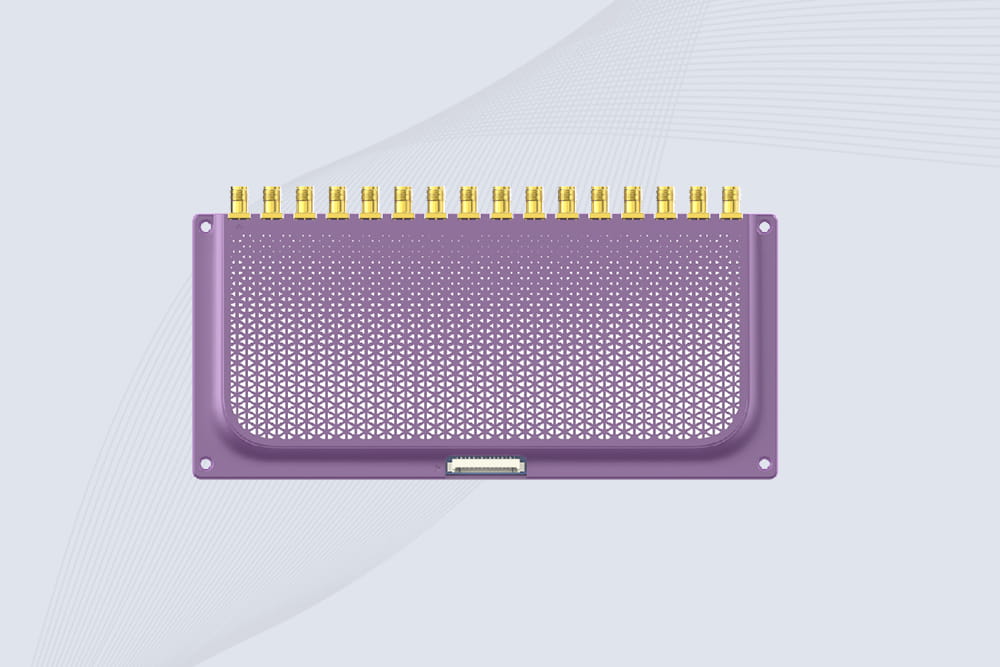

Learning how to make a rfid reader module is an excellent educational deep dive into RF principles. However, for any real-world application—access control, inventory—the performance, stability, and regulatory certification (FCC, CE) of a pre-built, professionally engineered module from a vendor like CYKEO are far superior and more cost-effective in the long run. Building one teaches you why those modules are worth every penny.

RFID Reader Module Recommendation

Cykeo RFID IoT Solution Products R&D Manufacturer

Cykeo RFID IoT Solution Products R&D Manufacturer