How to Make a 125kHz RFID Antenna: Prepare for a Lot of Coil Winding

You’ve got a 125kHz tag from an old access card and a reader chip kit. The missing piece is the antenna. So you search how to make a 125kHz RFID antenna. What you’ll find is that it’s a unique, tactile project—less about circuit boards and more about winding a perfect coil. It’s equal parts satisfying and maddening, and it’ll teach you exactly why most people just buy a pre-built reader module in the end.

The Core Truth: It’s Just a Big, Tuned Loop of Wire

Forget everything about UHF patch antennas. At 125kHz, we’re in the world of inductive coupling. The “antenna” is literally a large coil of wire—an inductor. Its job is to create a pulsing magnetic field. When you bring a tag’s coil inside this field, power transfers wirelessly (like a very basic, inefficient wireless charger), and data is swapped by how the tag loads the field.

Your mission is to wind a coil with a specific inductance (measured in Henries), then pair it with a capacitor to create a circuit that resonates (vibrates electrically) at exactly 125,000 times per second. This resonance is what makes the system sensitive and gives you a few centimeters of read range.

The Winding Process: More Art Than Science

Here’s the real process for winding a DIY LF antenna coil, stripped of theory:

- Grab Magnet Wire: You’ll need enameled copper wire, about AWG 24-26. Thinner wire is harder to work with but lets you fit more turns.

- Build a Frame: You can’t wind a coil in mid-air. Cut a rectangle from stiff cardboard or plastic, or use a small empty tape reel. Your coil’s outer dimensions set the stage.

- Start Winding (and Counting): This is the meditative, frustrating part. Wind turn after turn, as neatly and tightly as possible. You’ll likely need 80 to 150 turns for a decent-sized reader. Lose count? Start over. The exact number of turns directly controls the inductance.

- Measure, Don’t Guess: Once wound, use an LCR meter (a multimeter that measures inductance) to check your coil. You’re aiming for a value typically between 1 and 3 millihenries (mH). If you’re off, add or remove turns. This is the single most important step.

The Tuning Headache: Where Most DIY Projects Stall

You have a coil with, say, 1.8 mH of inductance. Great. Now you need to make it resonate at 125kHz. This requires adding a capacitor in parallel to create an LC tank circuit.

The formula is: Resonant Frequency = 1 / (2π √(L * C))

You need to solve for C (capacitance). For L=0.0018 H and Freq=125,000 Hz, C calculates to roughly 900 picofarads (pF).

So you solder a ~900pF capacitor across your coil leads. Does it work? Maybe. But here’s the catch: Stray capacitance from your breadboard and wires changes everything. You’ll almost certainly need a variable capacitor (or an array of switchable caps) to fine-tune it. You’ll tweak, test with a tag, tweak again, and chase that sweet spot of maximum read distance. Without an oscilloscope, you’re tuning blind.

Why Your Homemade Coil Will Frustrate You

Even if you get it working, you’ll face the classic problems with homemade RFID coils:

- Inconsistency: Bump the coil and the read range changes. The fragile hand-wound structure is easily deformed.

- Poor Range: A sloppy coil has a low Q factor (quality factor), meaning energy dissipates as heat in the wire rather than creating a strong magnetic field. Your range might be 1 cm instead of 5 cm.

- No Shielding: Your coil will be sensitive to every piece of metal around it and will radiate energy in all directions, making it unpredictable.

This is the gap between a functional prototype and a reliable product.

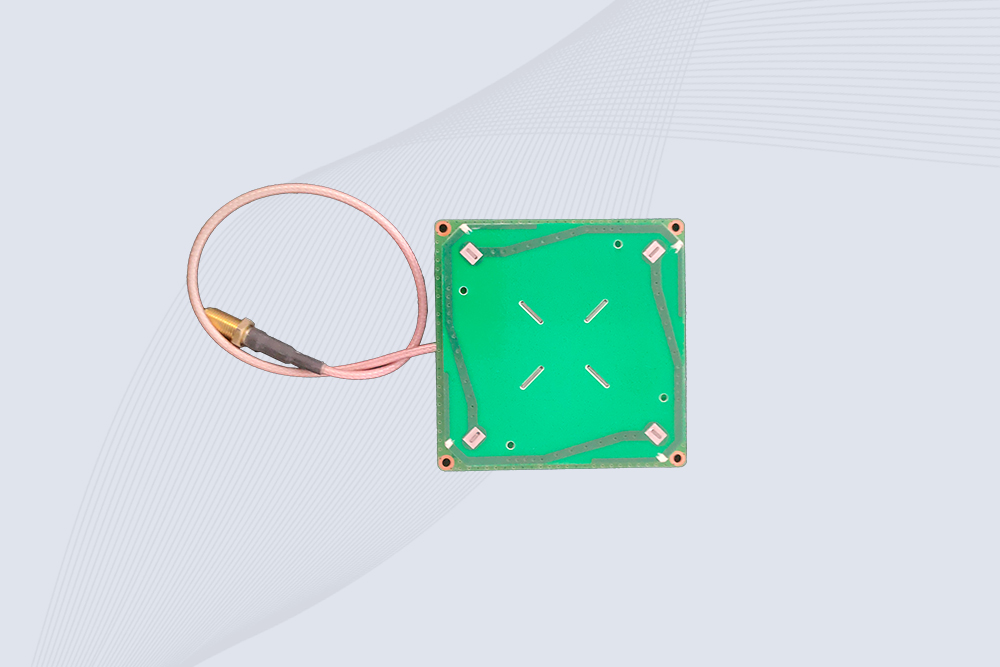

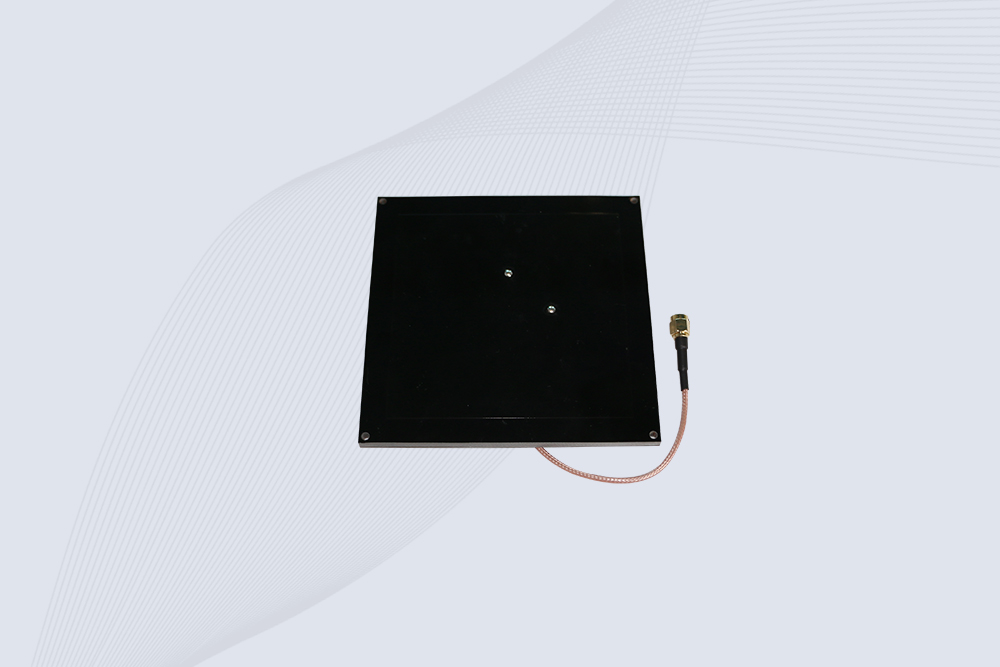

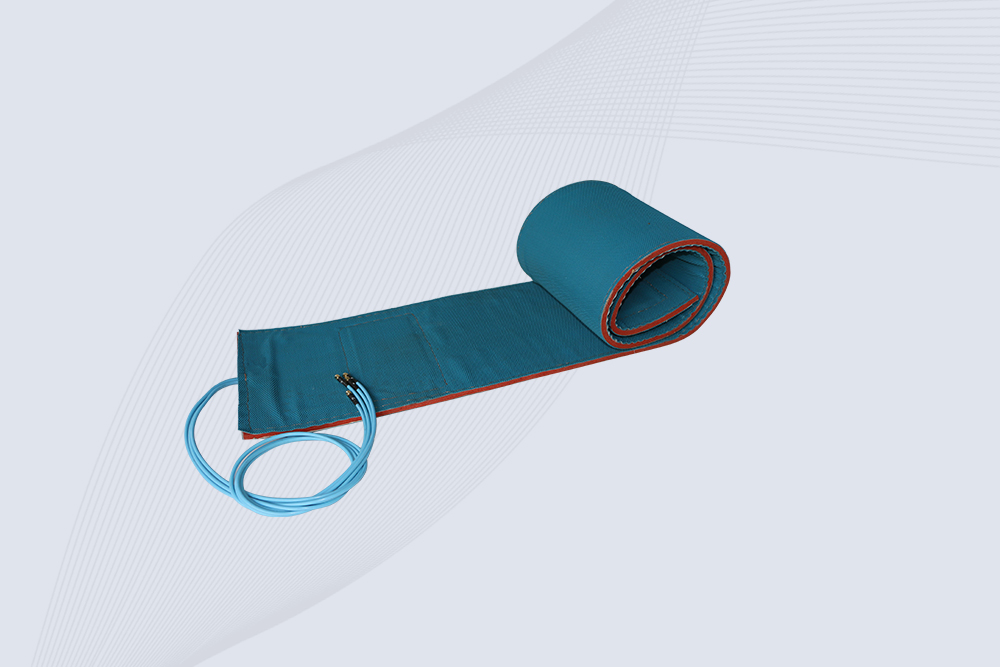

The Professional Alternative: Why Engineered Solutions Win

A commercial 125kHz RFID reader antenna isn’t just a wound coil. It’s a coil machine-wound on a ferrite core for efficiency and directional focus, potted in epoxy so it never moves, and shielded to ignore electrical noise. Its characteristics are identical in every single unit.

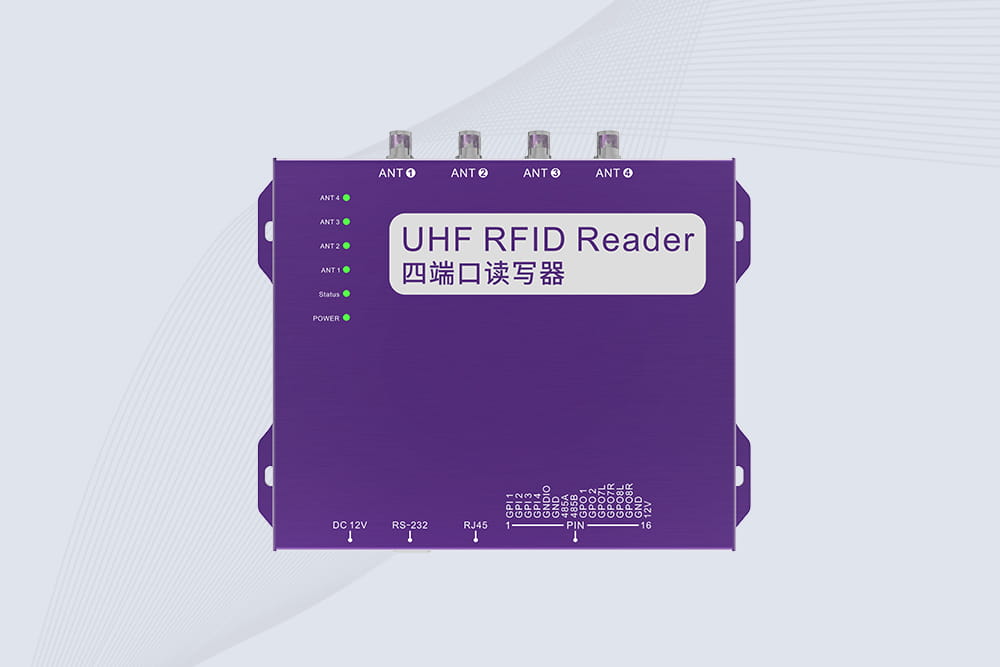

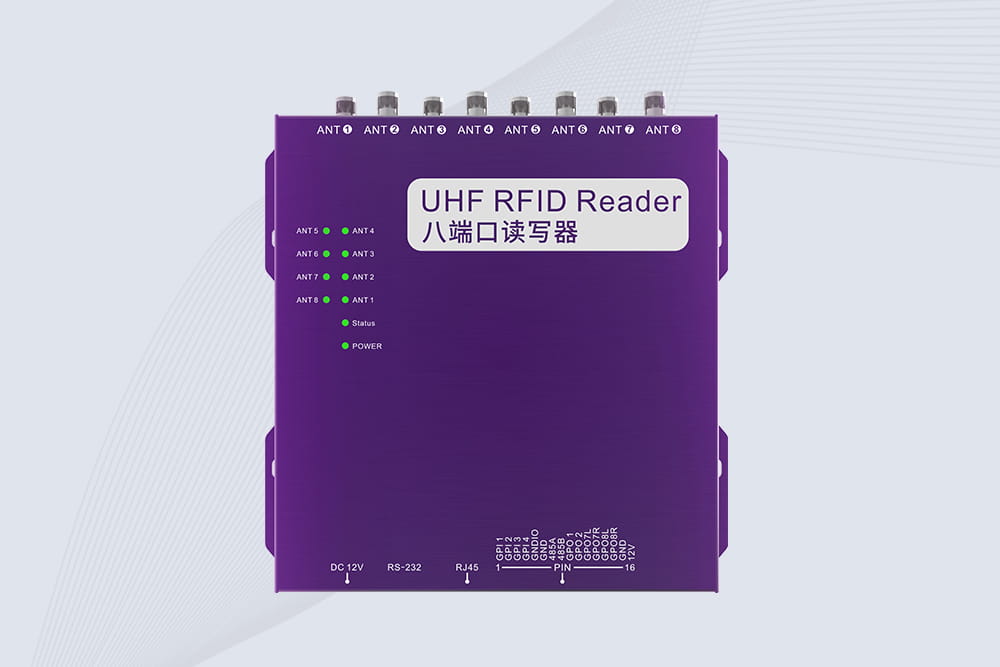

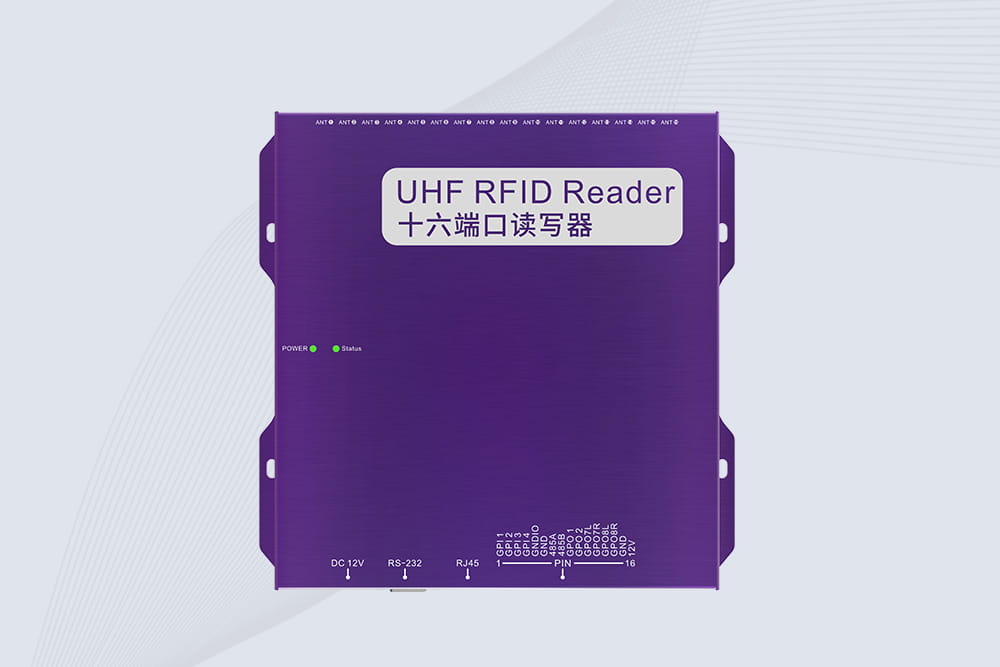

At CYKEO, we understand this engineering intimately. While our expertise is in advanced UHF systems, the principle is universal: reliability comes from precision manufacturing and robust design, not from hand-crafted components.

Learning how to make a 125kHz RFID antenna is a fantastic lesson in fundamental RF principles. You’ll gain a deep respect for the physics. But for a door access system, a time clock, or any application where “it works most of the time” isn’t good enough, the solution is to buy a pre-tuned, professionally built reader module. It saves time, guarantees performance, and lets you focus on your application, not on debugging a homemade coil.

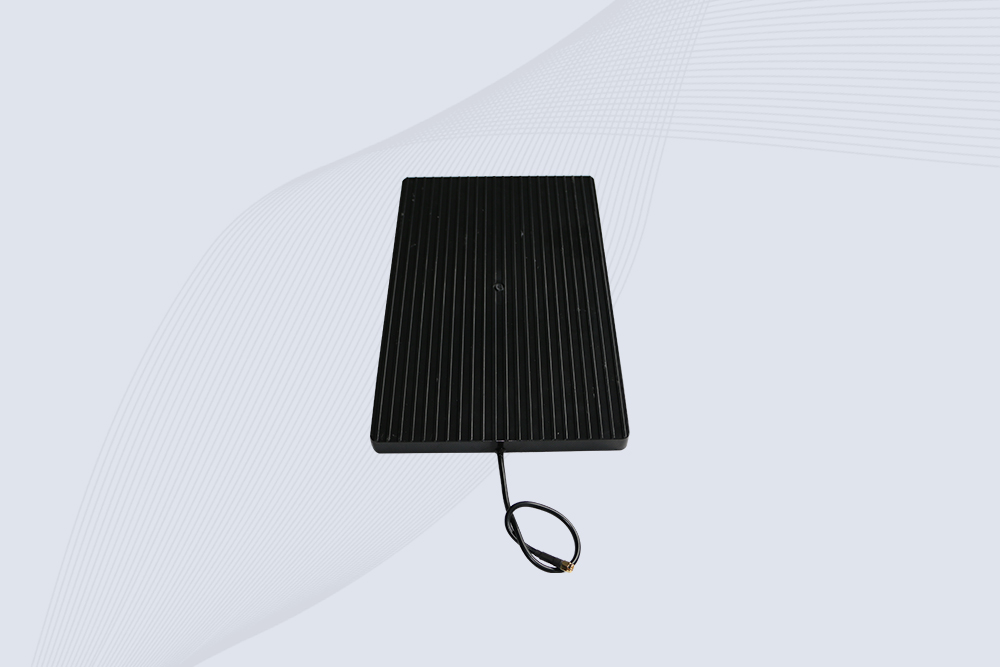

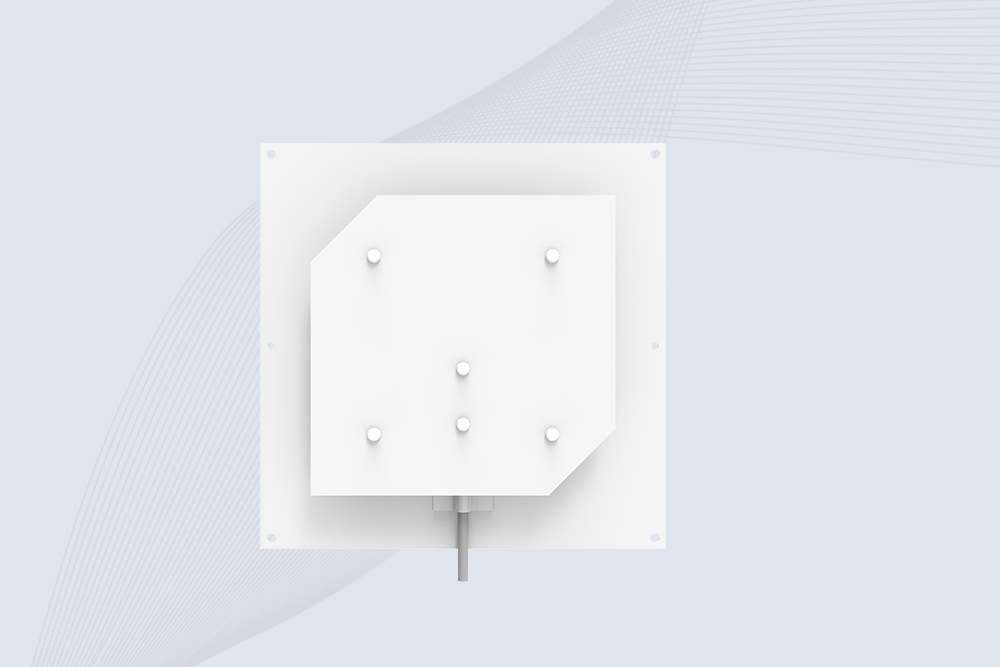

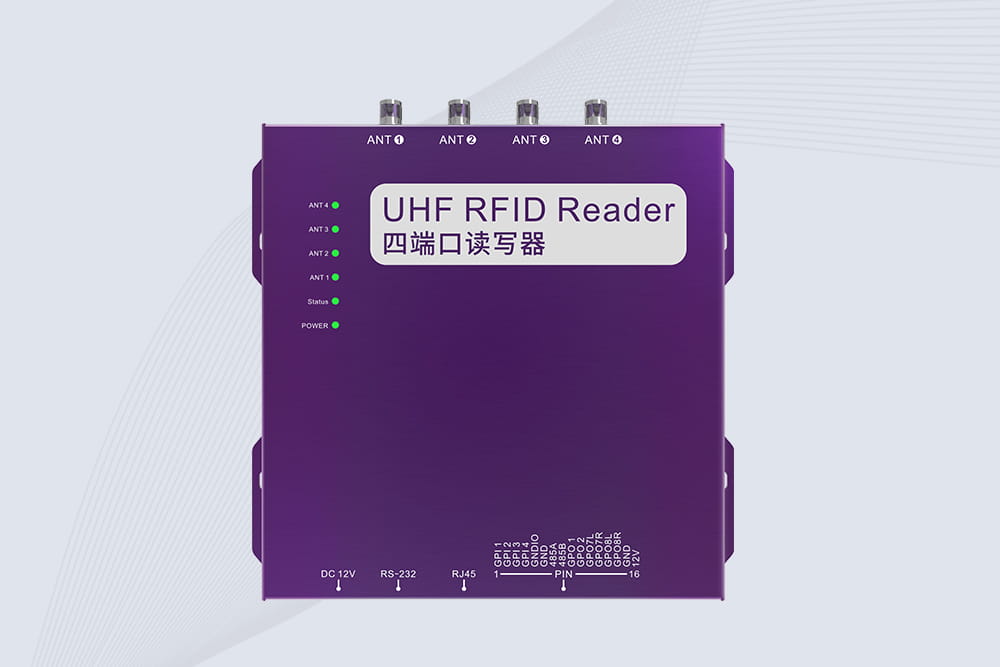

RFID Antennas Recommendation

Cykeo RFID IoT Solution Products R&D Manufacturer

Cykeo RFID IoT Solution Products R&D Manufacturer