What is an RFID Reader Module?

149Unsure what is an RFID reader module? This guide explains its role as the core hardware that powers access control, inventory tracking, and automated identification systems.

MoreAll RFID Product

Traditional inventory management methods are facing numerous challenges such as low efficiency and high error rates. The emergence of RFID technology has brought innovative changes to inventory management. So, how exactly is RFID applied to inventory management? And what unique advantages does it offer?

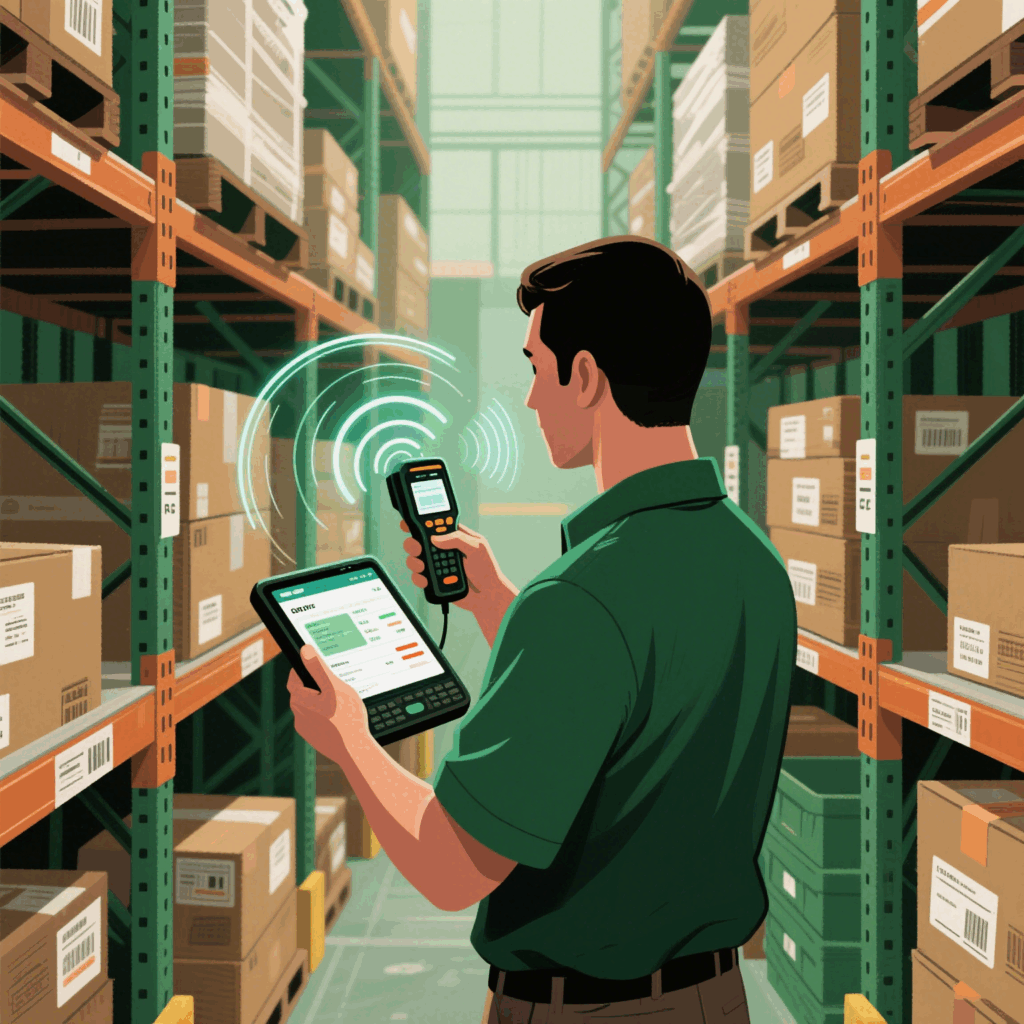

RFID technology enables non-contact automatic identification based on radio frequency signals. The system consists of RFID tags, readers, and antennas. Each RFID tag stores a unique identifier and related information of an item. When a tagged item approaches the reader, the reader emits a radio frequency signal through the antenna. The tag receives the signal and is activated, then reflects the stored information back to the reader in the form of electromagnetic waves. The reader decodes and processes the signal, thereby identifying the item and reading its information.

In warehouse environment, RFID technology is applied throughout various stages, including inbound, storage, inventory counting, and outbound processes. During inbound operations, staff no longer need to manually scan barcodes. Instead, goods with RFID tags can pass in batches through fixed readers installed at the warehouse entrance. The readers quickly capture all tag information, automatically complete inbound registration, and simultaneously record the goods’ data into the warehouse management system, updating inventory records.

In the storage phase, the system assigns appropriate storage locations based on the goods’ information and binds the location data to the RFID tags. When it is time to locate the items, staff can use handheld readers to quickly pinpoint the exact location of the goods, significantly improving picking efficiency.

Inventory counting is a key scenario where RFID technology delivers major advantages. Traditional stocktaking requires manual scanning of each item, which is time-consuming, labor-intensive, and prone to errors. With RFID, staff simply walk through the warehouse with a portable reader, which scans all tagged goods in a short period. The reader automatically compares the scanned data with the system records and generates an inventory report, precisely identifying any stock discrepancies.

During outbound operations, similar to inbound, readers installed at the shipping area automatically read the tags on the goods, completing shipment verification and updating inventory data to ensure accuracy of outgoing items.

Significantly Improved Efficiency: RFID technology enables fast, batch identification and reduces the need for manual operations. Whether it’s during receiving, shipping, or stocktaking, it greatly shortens processing time and enhances warehouse operational efficiency. For example, in large e-commerce warehouses, the use of RFID technology has increased goods handling speed by several times.

Enhanced Inventory Accuracy: Traditional inventory management methods are prone to data errors caused by human factors. RFID technology automatically reads and records information, avoiding issues such as missed or incorrect scans. As a result, inventory data can reflect actual stock levels in real time with accuracy rates exceeding 99%.

Real-Time Monitoring and Management: RFID systems can track the location and status of goods in real time. Managers can stay informed of inventory movements and make timely decisions regarding restocking or reallocation, effectively preventing stockouts or excess inventory.

Reduced Labor Costs: By minimizing manual scanning and data entry tasks, RFID reduces reliance on human labor and helps lower personnel costs.

Cykeo RFID smart warehouse management devices focus on item-level identification and demonstrate strong application potential across multiple industries.

In the apparel industry, each garment is tagged with an RFID label, enabling precise full-process management from production and warehousing to retail sales. During the receiving stage, entire boxes of clothing can be quickly counted without unpacking. For inventory checks, store staff can simply walk through the store with a handheld reader to complete the stocktake in minutes, greatly saving time and labor.

In the leather goods and luggage industry, Cykeo rfid inventory management devices ensure accurate recording of each item’s inbound and outbound data, preventing loss or misdelivery. For the alcoholic beverage industry, RFID labels offer effective anti-counterfeiting measures while enabling efficient inventory monitoring and traceability during storage.

In the power industry, Cykeo devices are used for precise management of power equipment and materials, ensuring the stability and safety of electricity supply.

RFID technology offers clear advantages, but businesses should also pay attention to several factors in practical applications. First, RFID equipment and systems should be selected based on business needs and budget. Second, employee training should be strengthened to ensure staff can operate RFID devices proficiently. In addition, data security and privacy protection must be emphasized to prevent the leakage of RFID tag information.

With continuous technological advancement and decreasing costs, RFID technology is set to see wider adoption in inventory management. It will bring greater efficiency and competitiveness to enterprises, leading warehouse management into a new era of intelligence and high performance.

Unsure what is an RFID reader module? This guide explains its role as the core hardware that powers access control, inventory tracking, and automated identification systems.

MoreLearn what an RFID programmer does, how it writes and configures RFID tags, and where it’s used in real applications like retail, logistics, and animal tracking.

MoreDiscover whether RFID or barcode systems deliver higher ROI for inventory management. Compare costs, accuracy, scalability, and real-world efficiency with Cykeo’s insights.

MoreDiscover durable textile RFID tags designed for industrial laundry, uniform, and linen tracking. Improve inventory accuracy, reduce loss, and manage textiles efficiently with long-lasting RFID laundry tags.

More