How to Reduce RFID Tag Read Errors in Fixed Reader Systems?

RFID tag read errors in rfid fixed reader systems often stem from signal interference, poor tag positioning, or environmental factors. By optimizing hardware setup, software configurations, and environmental controls, businesses can achieve >99% read accuracy. Below is a step-by-step guide using Cykeo’s industrial-grade RFID solutions to troubleshoot and resolve these issues.

1. Optimize Antenna Placement & Orientation

- Angle Adjustment:

- Position antennas at a 30°–60° angle relative to tagged items to maximize signal reflection and reduce null zones.

- For conveyor belts or shelves, use cross-polarized antennas to capture tags in multiple orientations.

- Height & Distance:

- Mount antennas 1–3 meters above tagged items, maintaining a 1–5 meter read range depending on tag type.

- Cykeo Tip: Use Cykeo’s RFID Site Planner Software to simulate signal coverage and dead zones.

2. Mitigate Environmental Interference

- Metal & Liquid Handling:

- Use anti-metal RFID tags (e.g., Cykeo’s MetalShield Series) to prevent signal detuning near steel shelves or machinery.

- Place tags 5–10 cm away from liquid containers to minimize absorption.

- EMI Reduction:

- Keep fixed readers 3+ meters from motors, Wi-Fi routers, or high-voltage equipment.

- Install ferrite cores on power cables to suppress electromagnetic noise.

3. Fine-Tune Reader Settings

- Power & Sensitivity:

- Adjust transmit power (27–33 dBm) and receiver sensitivity to balance range and noise.

- Enable Dense Reader Mode (DRM) in Cykeo’s software to reduce interference in multi-reader setups.

- Frequency Hopping:

- Activate FHSS (Frequency-Hopping Spread Spectrum) to avoid channel collisions with nearby devices.

4. Improve Tag Positioning & Quality

- Tag Placement Rules:

- Attach tags to flat, non-metallic surfaces. For curved items, use flexible inlays (e.g., Cykeo’s FlexTag).

- Ensure tags face the reader’s antenna; avoid folding or creasing.

- Tag Testing & Replacement:

- Audit tags quarterly with a handheld reader to identify failing units.

- Replace tags with read success rates <95%.

5. Environmental Controls

- Temperature & Humidity:

- Deploy Cykeo’s IP67-rated readers in humid or dusty environments.

- Use heated enclosures in sub-zero conditions to prevent condensation on antennas.

- Lighting & Obstructions:

- Avoid mounting readers under bright LED lights (can cause RF noise).

- Remove or reposition obstructions (e.g., stacked pallets) blocking the reader’s field.

6. Software & Data Filtering

- Middleware Integration:

- Use Cykeo’s SmartFilter Analytics to:

- Eliminate duplicate reads.

- Flag low-signal tags for manual verification.

- Real-Time Alerts:

- Set up notifications for sudden drops in read rates (indicative of hardware failure or interference).

Case Study: 99.5% Accuracy in Automotive Warehouse

- Challenge: A Cykeo RFID system in a German auto parts warehouse had 15% read errors due to metal shelves and EMI.

- Solution:

- Replaced standard tags with MetalShield tags.

- Adjusted antenna angles and activated DRM/FHSS.

- Result:

- 99.5% read accuracy and 50% faster inventory audits.

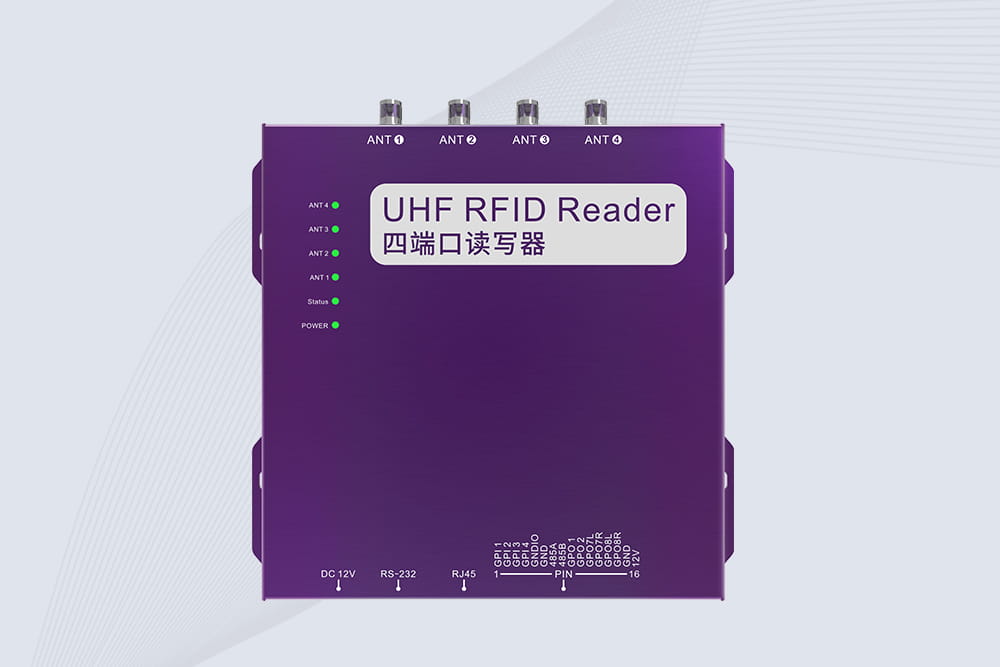

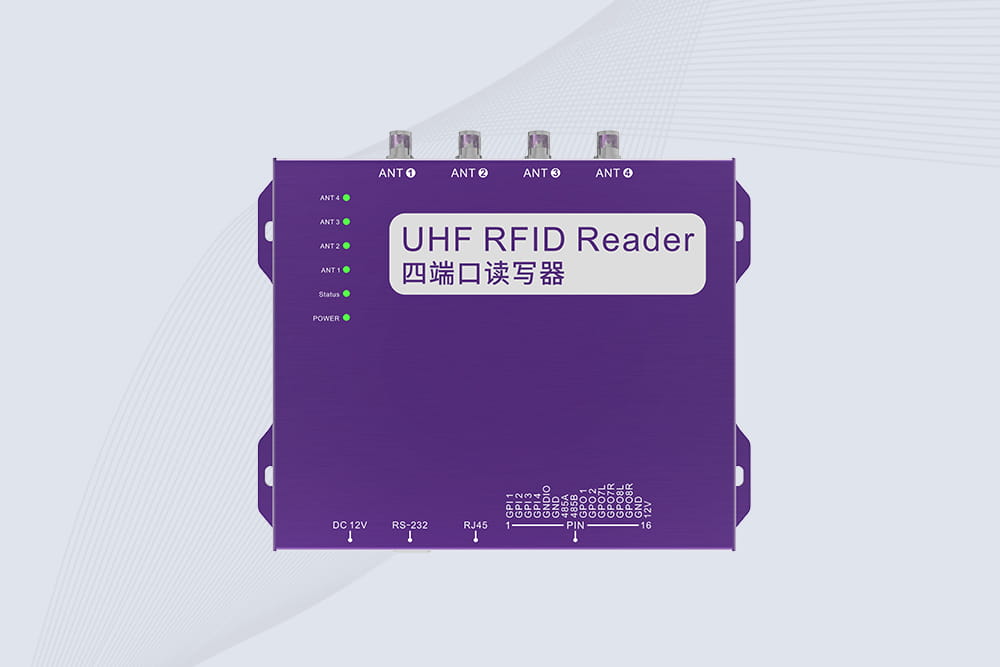

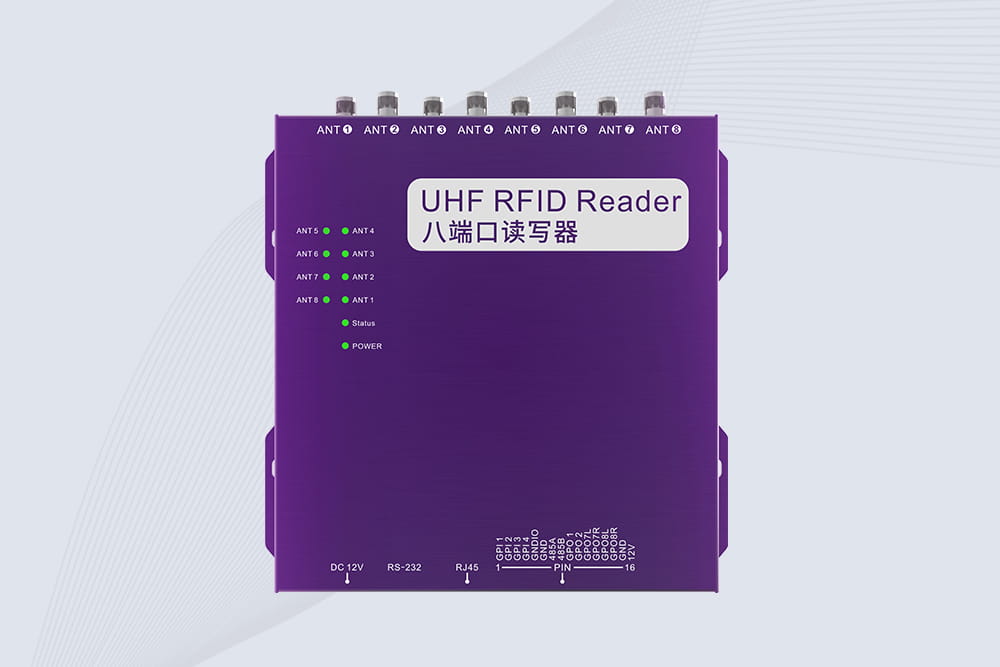

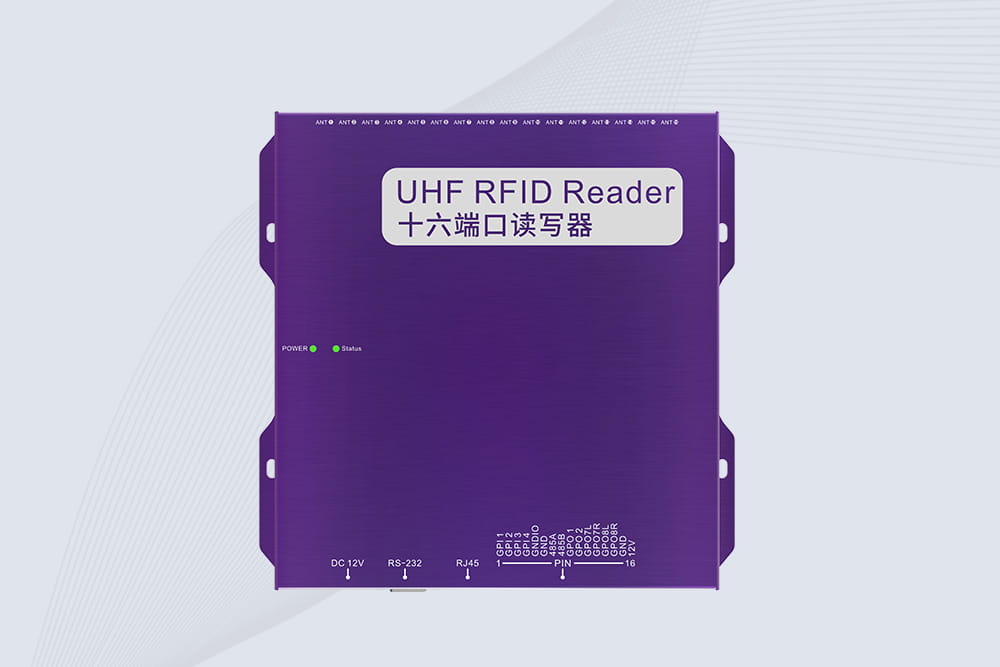

fixed RFID reader systems

Cykeo RFID IoT Solution Products R&D Manufacturer

Cykeo RFID IoT Solution Products R&D Manufacturer