Effective Range Of Rfid UHF Tags

975UHF RFID tags, with their unique performance advantages, have become the preferred choice for businesses aiming to improve operational efficiency.

MoreAll RFID Product

In a warehouse, busyness is almost constant. Forklifts weave between high stacks of shelves, and workers scan inventory one shelf at a time. Missed scans, double scans, and occasional mistakes happen daily. Then I saw the RFID ceiling reader—a silent pair of eyes changing the rhythm of the warehouse.

What exactly is a ceiling reader?

In simple terms, it’s an RFID reader mounted on the ceiling or high up, using multiple antennas to read tags from above. Compared with handheld scanners, it has clear advantages: it covers a large area, doesn’t take up floor space, and can almost automatically track inventory.

I visited a medium-sized logistics warehouse in Qingpu, Shanghai, where several ceiling readers were installed above entry and exit aisles. The moment a truck opened its doors, the system displayed the incoming or outgoing goods within seconds. Workers didn’t need to pause their picking tasks, and the warehouse rhythm became noticeably smoother.

Of course, this isn’t magic. Items placed low sometimes get missed, especially in warehouses with very high ceilings or irregular shelf layouts. This is why experience matters—no matter how advanced the technology, it still needs humans to work with it.

Different Approaches and Practical Insights

Installation and Usage Tips

I’ve realized that the best technology leaves space to breathe. Ceiling readers make a warehouse less of a battlefield and more controllable and visible.

Why It’s Worth Trying

RFID ceiling readers don’t just boost efficiency—they make management easier and more intuitive. You can see inventory movements as they happen, catching problems immediately instead of waiting for month-end reports. For small to medium businesses, the initial cost is higher, but savings in labor and reduced errors make it worthwhile.

Looking ahead, ceiling readers may integrate with AI and data analysis, not just “seeing” items, but predicting shortages, optimizing restocking, and even analyzing customer traffic. They won’t replace humans—they’ll let staff focus on higher-value work while preserving human judgment.

Conclusion

If you’re thinking of automating your warehouse, ceiling readers deserve attention. They may not fix everything, but they smooth out workflows and reduce repetitive strain. Real-world experience proves that technology and humans must collaborate for a warehouse to be smart yet human-friendly.

Cykeo CYKEO-C1 industrial Forklift RFID Reader features 20m read range, 600 tags/sec scanning, Impinj R2000 chipset, and IP67 rugged design. Ideal for warehouse logistics and manufacturing. Supports ISO 18000-6C/6B protocols.

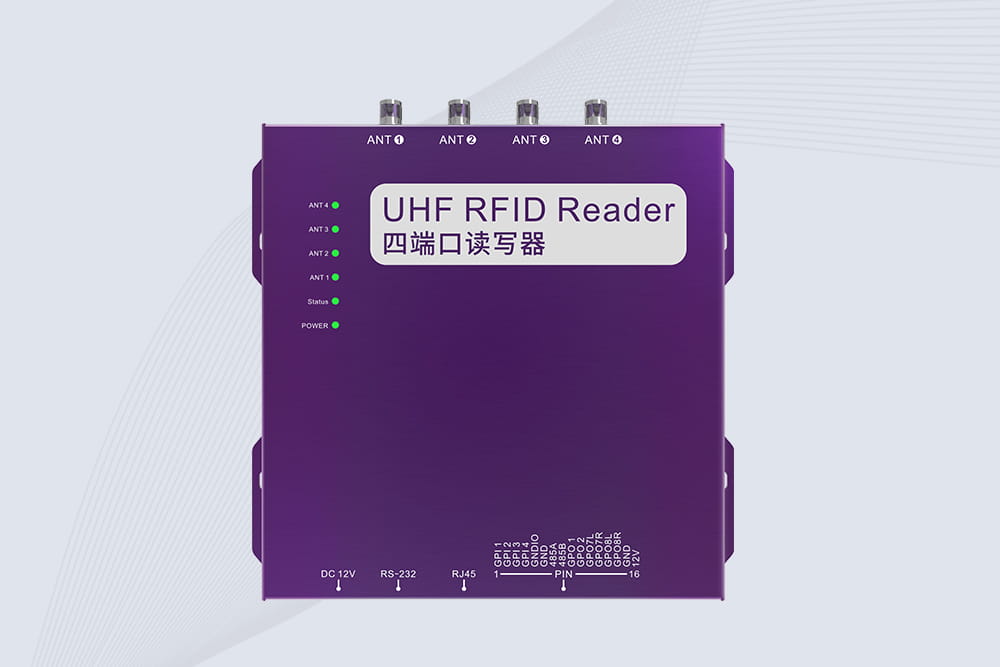

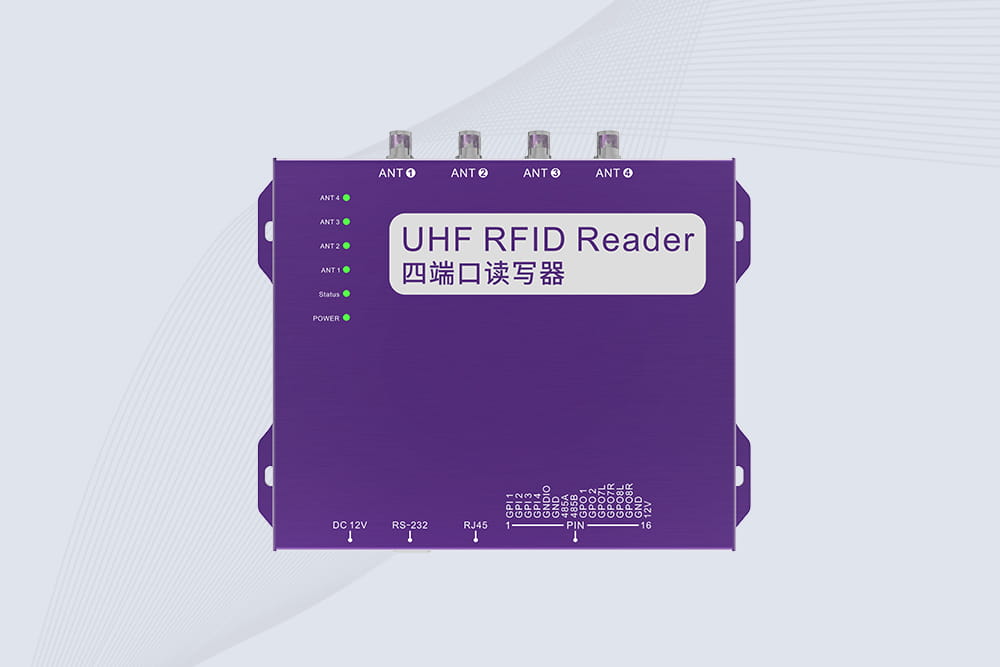

Cykeo CYKEO-R4 industrial UHF RFID Fixed Reader features 4 TNC ports, 400+ tags/sec speed, IP67 housing, and global frequency compliance for vehicle inspection, smart warehouse, and asset management systems.

Cykeo’s CYKEO-R4L 4-port Fixed UHF RFID Reader delivers 400 tags/sec scanning, ISO 18000-6C compliance, and IP65 protection. Ideal for warehouse automation, manufacturing WIP tracking, and logistics management.

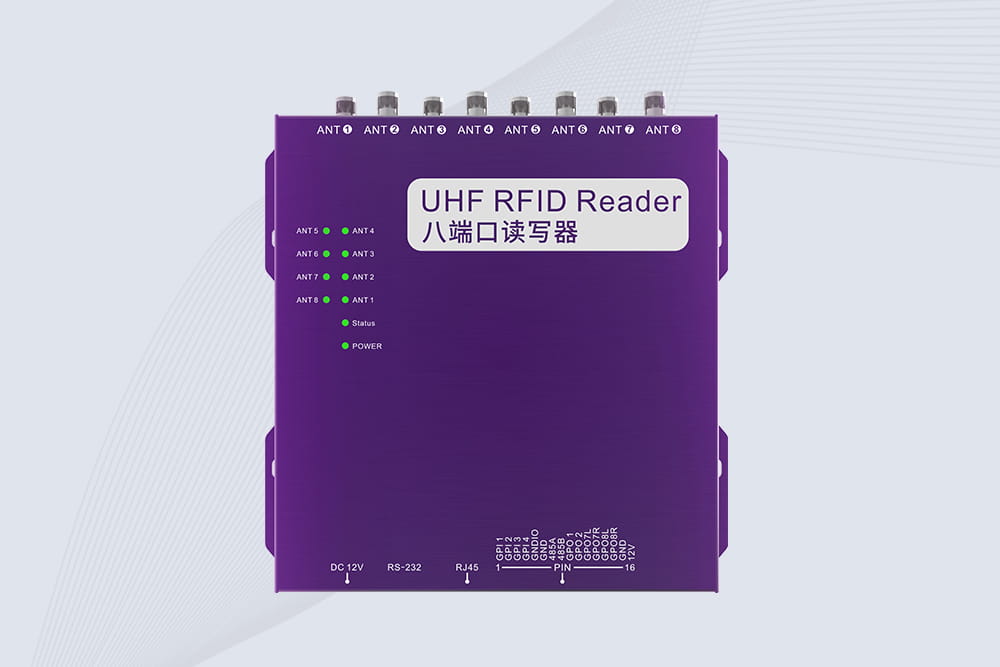

CYKEO CYKEO-R8L Fixed RFID Reader with 8-port UHF design, Impinj-based RF core and up to 20m read range. An industrial Fixed RFID Reader for vehicle inspection, warehouse portals, smart manufacturing lines and secure access checkpoints.

UHF RFID tags, with their unique performance advantages, have become the preferred choice for businesses aiming to improve operational efficiency.

MoreThis article provides detailed guide on how to use an Android phone to emulate RFID tags, covering prerequisites, HCE principles, development steps, and practical B2B applications such as access control testing and IoT device prototyping.

MoreA practical guide to RFID USB readers, focusing on real application scenarios, tag writing workflows, and how developers use USB RFID readers for testing, encoding, and system integration.

MoreExtend your handheld RFID scanner’s battery life for field operations. Learn Cykeo’s tips on power settings, battery care, and energy-efficient workflows.

More