How to Use Handheld RFID Readers for Livestock Tracking on Farms?

432Learn how to track livestock efficiently using handheld RFID readers. Discover best practices for tagging, data collection, and integrating with farm management software.

MoreAll RFID Product

Walk into any busy warehouse, hospital, or airport today, and you’ll notice something subtle but revolutionary — things are finding themselves. Not through magic, but through small, almost invisible devices quietly pulsing data through the air. These are RFID tracking devices, the unsung heroes of modern logistics and asset management.

Every RFID system starts with one simple but powerful idea — give every asset a digital identity.

RFID tracking devices, whether embedded in a label or bolted onto a machine, store a unique code that can be wirelessly read by an RFID reader. No barcode scanners, no manual entry — just radio waves bouncing through space, identifying dozens or even hundreds of items in seconds.

It sounds high-tech, but the beauty is in its simplicity. You stick a tag on a toolbox, a laptop, or a shipment pallet, and suddenly that object becomes part of a live data ecosystem. The tag doesn’t need a battery if it’s passive; it simply wakes up when an RFID reader sends a signal nearby, responds with its ID, and goes back to sleep.

That’s why warehouses can scan entire shelves at once, and why hospitals can locate critical equipment without running from room to room.

Let’s strip away the jargon. Think of it as a conversation:

This interaction happens at high speed and can cover several meters, depending on the type of device and antenna setup.

In busy environments — like a production floor or logistics hub — this means workers don’t have to scan each item individually. The system quietly collects all the data in the background, feeding it to a database where location, status, and usage history are updated in real time.

If you’ve ever spent hours searching for misplaced tools or equipment, RFID technology feels like a miracle.

But the real benefits go deeper:

That’s not just convenience; it’s operational intelligence. RFID tracking devices turn “we think it’s somewhere in the building” into “it’s on shelf B3, scanned 14 minutes ago.”

Of course, not everything about RFID is plug-and-play.

RFID tracking devices don’t perform well in every environment. Metal surfaces can reflect radio waves, liquids can absorb them, and dense materials can block them entirely. Choosing the right tag type — one built for your conditions — matters more than the technology itself.

Then there’s placement. Tagging every asset is one thing; knowing where to tag it is another. A misplaced tag can mean no reads at all. In the real world, this means testing, retesting, and sometimes a little creative engineering (like embedding tags into plastic handles or mounting them on brackets).

And finally, the human factor. A new system is only as good as the people using it.

Training teams to trust automation — to let the devices do the counting — can take time. But once they experience the efficiency firsthand, there’s no going back.

What’s exciting about RFID tracking devices isn’t just knowing where things are — it’s knowing how they move.

Imagine coupling RFID with sensors that detect temperature, humidity, or motion. Now you’re not only tracking assets; you’re monitoring their health, usage, and even potential failure.

For manufacturers, this means real-time insights into production flow. For logistics operators, it means visibility from dock to destination. For everyday users, it’s the quiet assurance that their assets aren’t just labeled — they’re alive in the data stream.

The future isn’t about tagging more things; it’s about making the tagged world more intelligent.

RFID tracking devices are the invisible infrastructure of modern operations. They don’t shout for attention, but they make everything else run smoother — from asset security and inventory control to predictive maintenance and workflow automation.

In an age where data is the new currency, RFID isn’t just another tech acronym.

It’s the bridge between the physical and the digital — between “where it is” and “what it means.”

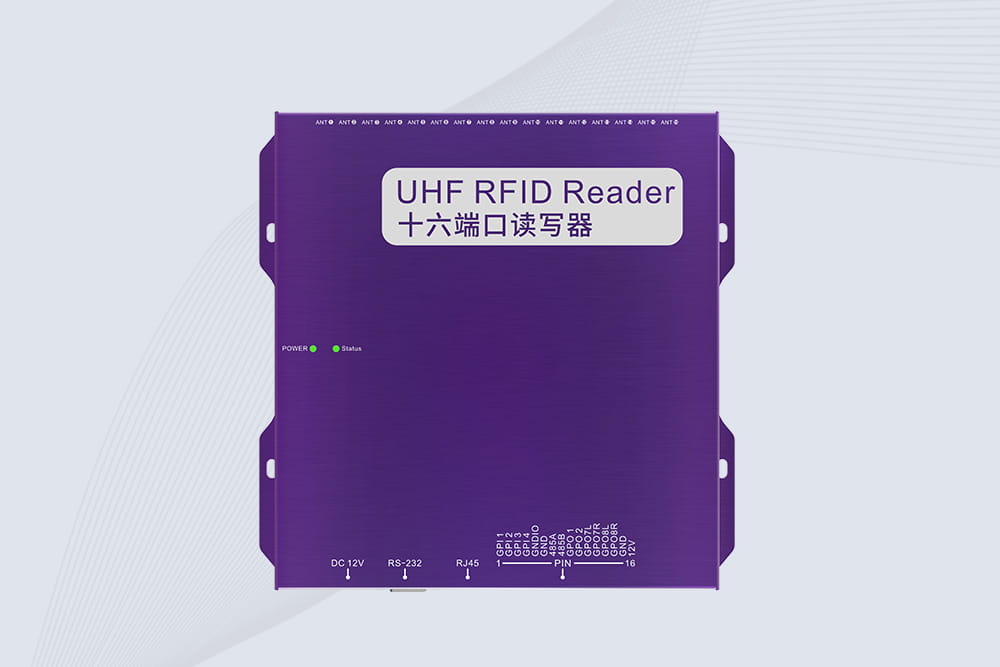

Cykeo CK-R16L UHF RFID fixed reader offers 16-channel scanning, 15m range, ISO 18000-6C compliance, and rugged design for smart lockers/warehouses. Integrates with WMS via TCP/IP.

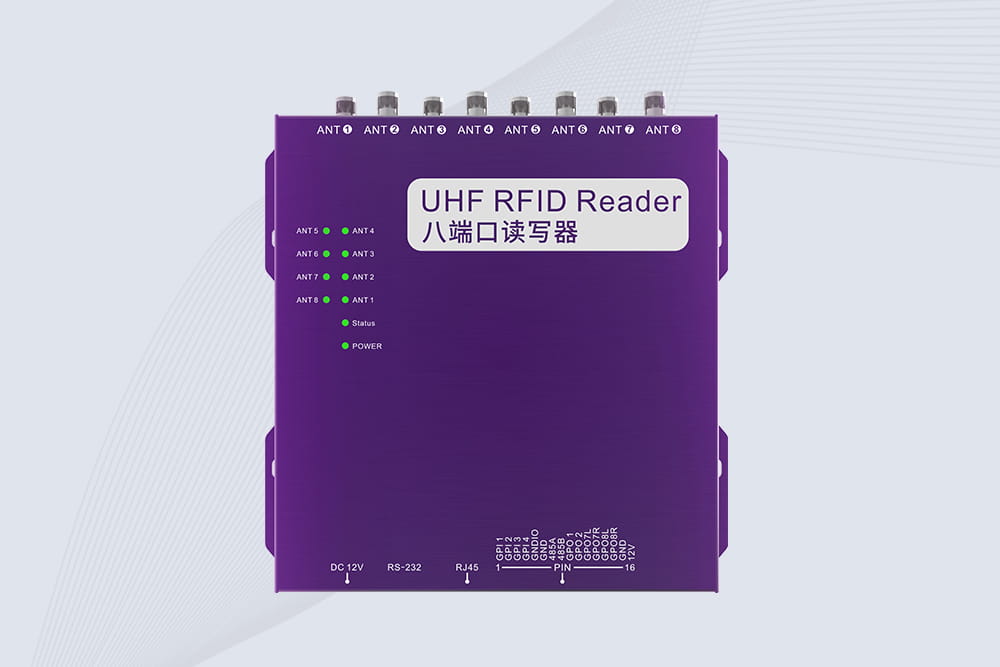

Cykeo’s CK-R8L UHF fixed RFID reader offers 8-antenna management, 20m range, and GB/T29768 compliance for automated logistics, manufacturing, and access control. Features Android 4.4, 33dBm power, and industrial I/O.

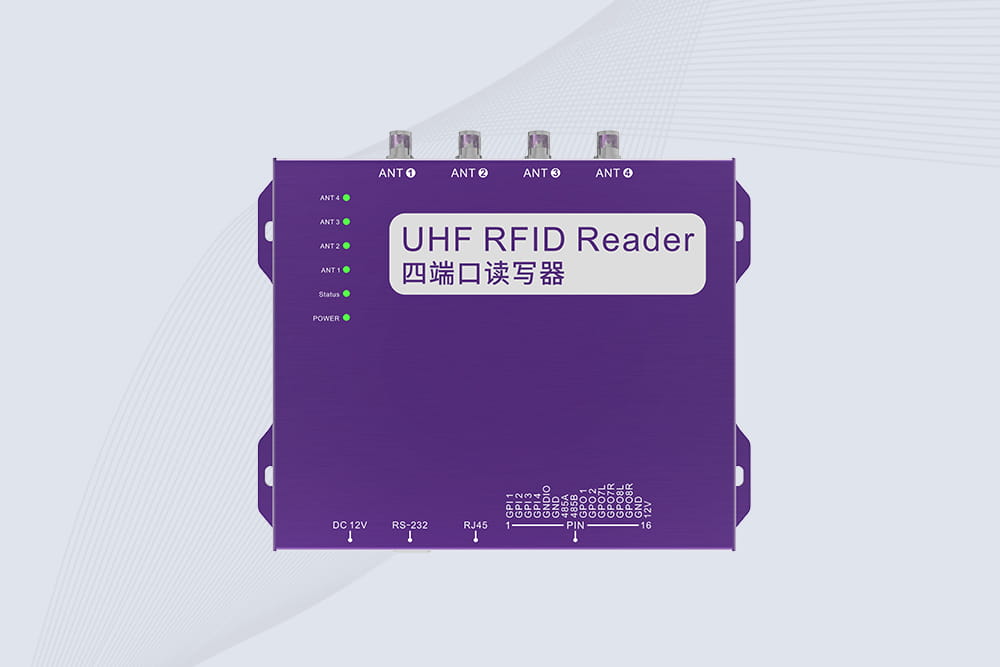

Cykeo’s CK-R4L 4-port Fixed UHF RFID Reader delivers 400 tags/sec scanning, ISO 18000-6C compliance, and IP65 protection. Ideal for warehouse automation, manufacturing WIP tracking, and logistics management.

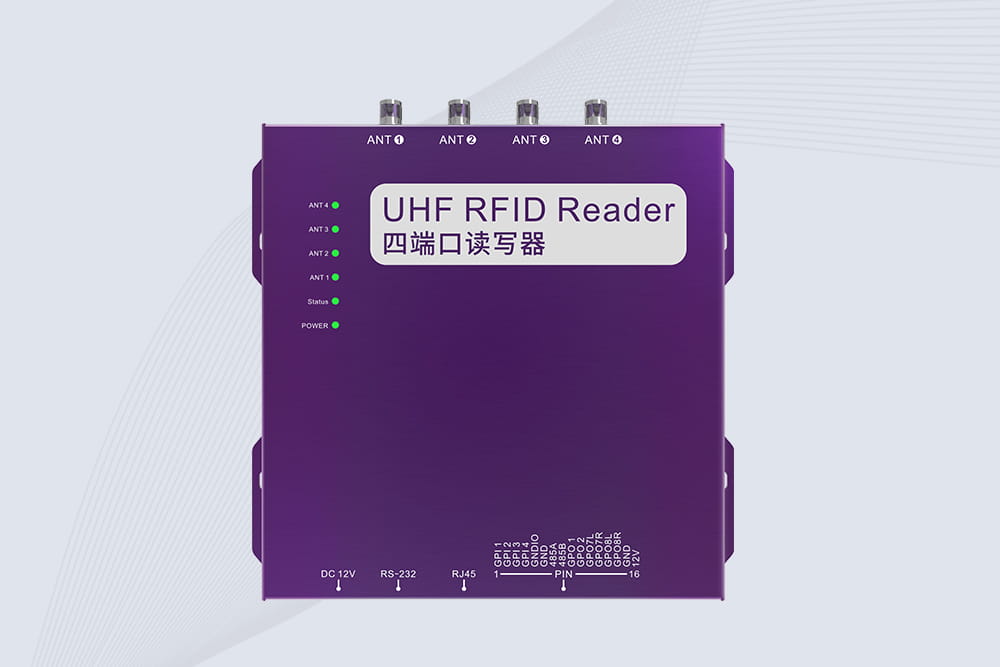

Cykeo CK-R4 industrial UHF RFID Fixed Reader features 4 TNC ports, 400+ tags/sec speed, IP67 housing, and global frequency compliance for vehicle inspection, smart warehouse, and asset management systems.

Learn how to track livestock efficiently using handheld RFID readers. Discover best practices for tagging, data collection, and integrating with farm management software.

MoreDiscover how RFID technology transforms retail operations—reduce stockouts, improve inventory accuracy, and deliver seamless customer experiences.

MoreRFID technology has extensive applications in the medical field, contributing in the following areas: Records ManagementRFID enables the rapid and accurate identification and tracking of medical records, including patient files, examin...

MoreCompare RFID and NFC technologies for asset tracking, payments, and more. Discover which wireless solution fits healthcare, retail, or manufacturing.

More