RFID in Retail: How to Streamline Inventory and Enhance Customer Experience

462Discover how RFID technology transforms retail operations—reduce stockouts, improve inventory accuracy, and deliver seamless customer experiences.

MoreAll RFID Product

Inventory management has always been a balancing act. Too much stock ties up cash, too little stock kills sales. For years, barcode scanners were the go-to tool. But once you start working with an RFID scanner inventory setup, the difference in speed and accuracy is like moving from a bicycle to a motorbike.

That said, RFID isn’t magic. It comes with its own quirks, and knowing how to deploy it properly makes all the difference.

Instead of lining up a barcode and scanning one by one, RFID scanners use radio waves to capture tag data in bulk. You can literally walk past a shelf with a handheld reader and capture hundreds of items in seconds. No line of sight needed.

In practice, I’ve seen RFID scanners pick up boxes stacked three rows deep, something barcode systems simply can’t handle. But the catch is, the environment matters—metal shelves or liquid containers can block or bounce signals, creating blind spots.

I once ran a trial in a medium-sized parts warehouse. The first week, staff were skeptical. After two rounds of cycle counts, they were sold—what took two hours with barcodes was cut down to fifteen minutes.

If you’re new to RFID, don’t jump straight into a full-blown automated gate system. Start small:

Do a “walk test”—carry a tagged item through your scanning zone to check coverage. This little trick reveals blind spots before you spend big on fixed readers.

The push for real-time visibility in supply chains isn’t slowing down. Whether it’s retail shelves, hospital equipment, or manufacturing parts, RFID scanning offers a level of control that barcodes simply can’t match.

The upfront cost is higher, but in my experience, the savings in time, accuracy, and reduced stockouts more than pay for it. The key is not to treat it as a fancy gadget, but as a tool you tune to your workflow.

An rfid scanner inventory system can transform stock management from a tedious chore into a streamlined process. But like any tool, success depends on setup and discipline: consistent tagging, realistic expectations on read range, and proper software integration.

Think of RFID scanning not as replacing barcodes, but as upgrading to a system built for today’s fast, multi-channel operations. Once you’ve tried it in action, it’s hard to imagine going back to manual counts.

Cykeo CK-C1B RFID to track inventory system features 800+ items/hour scanning, telescopic antenna, and real-time shelf analytics for libraries/warehouses. Supports Windows/Android OS.

Cykeo CK-C1A RFID tag inventory system features vertical 2.2m manual lift, dual antennas, and Android/Windows OS for warehouse/library inventory. Supports SAP/Oracle integration.

Cykeo CK-T8B industrial rfid gate access system offers 1.85m scanning corridor, 99.6% read accuracy, and Windows/Android OS for production line verification. Supports SAP/Oracle integration.

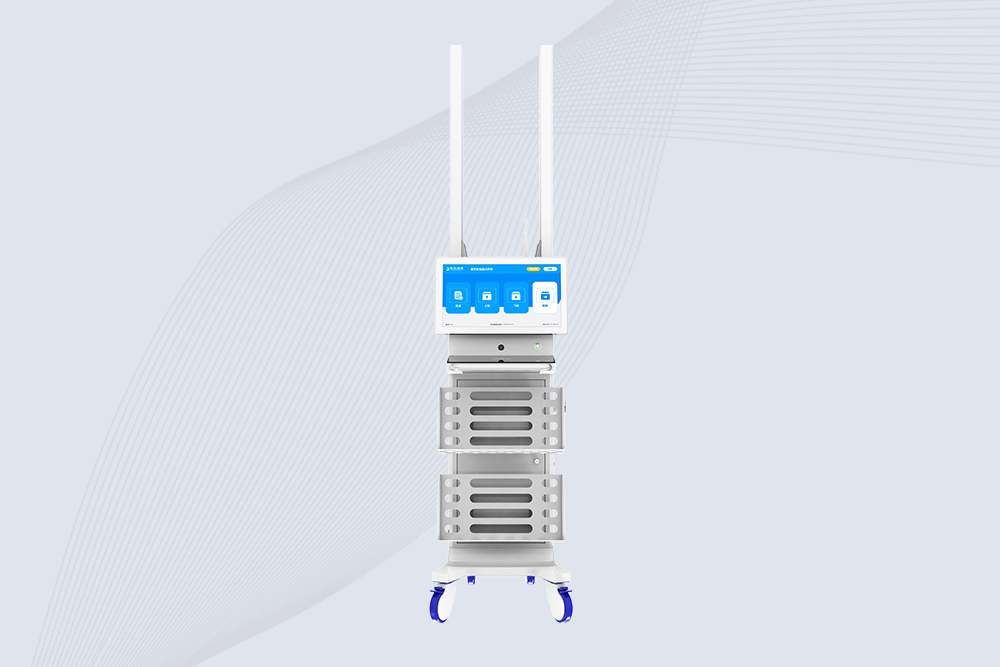

Cykeo CK-C4C RFID inventory tracking cart features 10-antenna array, 300+ items/min scanning, and SAP integration for real-time asset visibility in warehouses/hospitals.

Discover how RFID technology transforms retail operations—reduce stockouts, improve inventory accuracy, and deliver seamless customer experiences.

MoreDiscover Cykeo CK-B2G, a rugged UHF RFID handheld reader with 20m range, Android 13 OS, 12-hour battery life, and multi-protocol support. Perfect for logistics, warehousing, and retail.

MoreThis article systematically introduces the application value of rfid stickers for inventory in stock management, covering common tag types, functional features, and applicable scenarios to help enterprises select suitable options and improve asset...

MoreLearn how to pair your Bluetooth RFID reader with an Android tablet in 5 minutes. Fix connection drops, optimize scans, and use Cykeo’s tools for inventory or events.

More