How to Troubleshoot Connectivity Issues with RFID Handheld Scanners?

559Learn how to resolve RFID handheld scanner connectivity issues. Follow step-by-step fixes for Bluetooth, Wi-Fi, and hardware problems with Cykeo’s troubleshooting tips.

MoreAll RFID Product

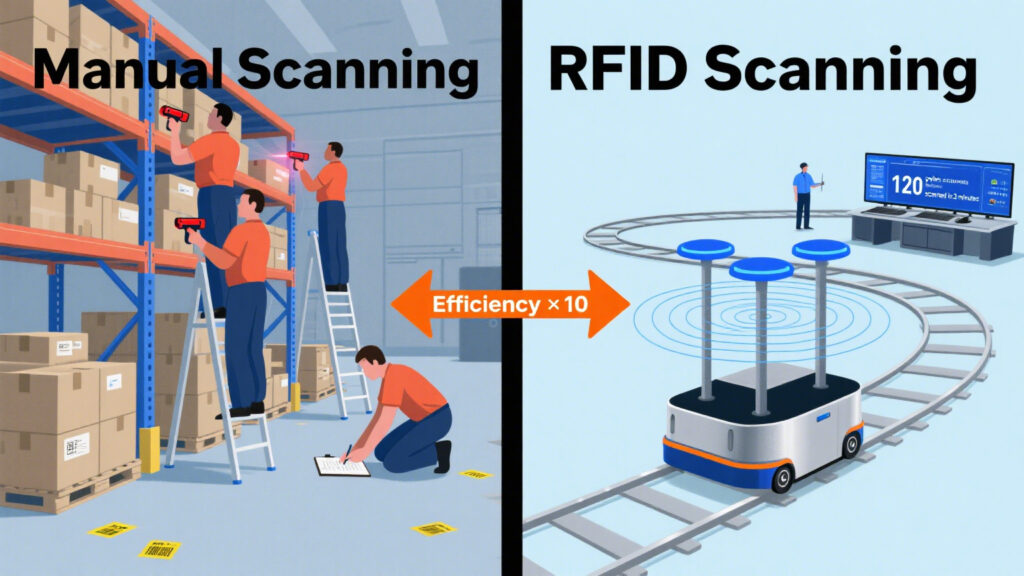

The first time I saw RFID at work, I honestly thought it was overkill. A truck pulled in, pallets rolled through a gate, and somehow everything got logged without anyone stopping to scan. It felt like cheating compared to the old barcode gun routine.

Warehouses are messy. Boxes stacked wrong, labels ripped, scanners dying right when you need them. Barcodes help but only if people actually scan every single thing. RFID takes away some of that human step. I’ve seen inventory that used to drag across two full shifts get wrapped up before lunch. That’s the kind of change people remember.

Of course, it’s not magic. Metal racks, liquids, shiny surfaces—RFID hates those. We once had a batch of washing machines that just refused to read unless you stood in one weird corner waving the scanner like a wand. Honestly, a kid with a barcode reader would have finished faster. That day I stopped believing the “flawless automation” sales pitch.

Then there’s the cost. Readers, antennas, cables—it adds up. Smaller warehouses look at the numbers and laugh. And even when you do set it up, what you get isn’t “real-time GPS.” It’s just: “last seen near Dock 4 at 10:37.” Useful, yes, but not the futuristic tracking dashboard vendors like to show in slides.

Fashion retail is the one place I’d say RFID earns its keep. Counting clothes piece by piece is torture. With RFID you sweep a handheld around and you’re done in minutes. Cold storage is another: tags plus sensors keep both stock and temperature in check, which saves fights later.

RFID in warehouse management isn’t the silver bullet it’s often sold as. Sometimes it shines, sometimes it’s more trouble than it’s worth. I’d say it’s a tool, not a solution. If you expect it to solve all your problems, you’ll be disappointed. If you just want to save time on the tasks everyone hates, it’s worth a shot.

Like a supervisor told me once: “Don’t buy a forklift to move a chair. And don’t use a hand truck when you’re hauling a pallet.”

Cykeo CK-C1B RFID to track inventory system features 800+ items/hour scanning, telescopic antenna, and real-time shelf analytics for libraries/warehouses. Supports Windows/Android OS.

Cykeo CK-C1A RFID tag inventory system features vertical 2.2m manual lift, dual antennas, and Android/Windows OS for warehouse/library inventory. Supports SAP/Oracle integration.

Cykeo CK-T8B industrial rfid gate access system offers 1.85m scanning corridor, 99.6% read accuracy, and Windows/Android OS for production line verification. Supports SAP/Oracle integration.

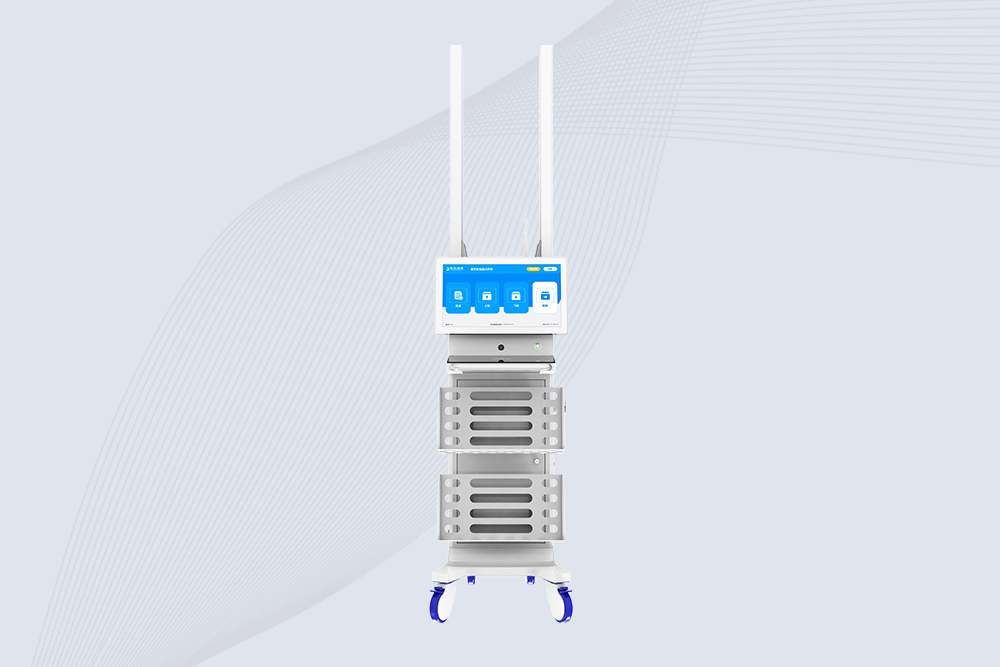

Cykeo CK-C4C RFID inventory tracking cart features 10-antenna array, 300+ items/min scanning, and SAP integration for real-time asset visibility in warehouses/hospitals.

Learn how to resolve RFID handheld scanner connectivity issues. Follow step-by-step fixes for Bluetooth, Wi-Fi, and hardware problems with Cykeo’s troubleshooting tips.

MoreDiscover how to select the best handheld RFID reader for warehouse inventory. Learn key features like durability, read range, and software integration for optimal efficiency.

MoreAs technology continues to advance, Radio Frequency Identification (RFID) technology has found applications across various fields. In identity verification, RFID offers unique advantages, providing innovative solutions for safeguarding pr...

MoreIn real-world RFID projects, off-the-shelf products often fail to meet site-specific requirements. Whether it’s chips, tags, or readers, custom RFID solutions can address these challenges. This article shares practical insights and examples for in...

More