How to Maintain Fixed RFID Readers in High-Dust Environments?

473Learn how to maintain fixed RFID readers in high-dust environments. Discover Cykeo’s dustproofing strategies, cleaning routines, and firmware updates for reliable performance.

MoreAll RFID Product

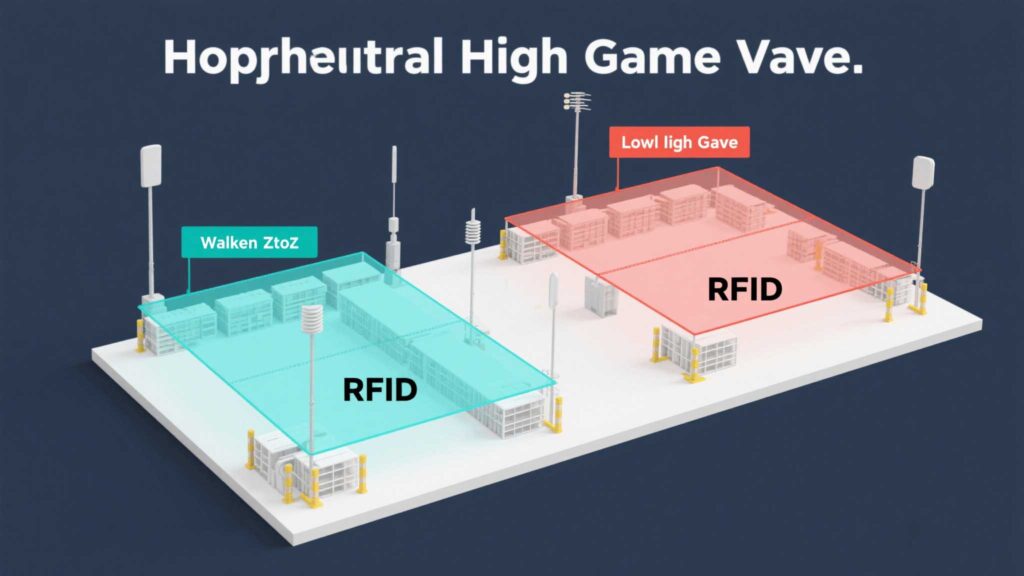

In warehouses, where every second counts, the wrong RFID antenna can turn a streamlined operation into a bottleneck of missed tags and frustrated staff. Antenna size and gain aren’t just technical specs—they’re the difference between seamless automation and manual chaos. Here’s how to match these critical factors to your warehouse’s unique demands.

RFID antennas act as the “eyes” of your tracking system. Their physical size and gain (signal strength) determine:

Key Trade-Off: Larger antennas with higher gain offer longer reach but narrower beams. Smaller antennas cover less area but work better in tight spaces.

Antenna choices depend on your facility’s structure:

Pro Tip: Use CAD software or RFID simulation tools to model signal spread based on rack heights and pathways.

Case Study: A Cykeo client reduced missed reads by 68% in a 20,000 sq. ft. warehouse by switching from 60cm to 30cm antennas in narrow aisles, improving picker efficiency.

Gain (measured in dBi) determines how far signals travel—but higher isn’t always better.

Formula Quickie:

Coverage Diameter≈Beamwidth (in radians)Antenna Height×2

(Example: A 6 dBi antenna at 4m height covers ~15m diameter.)

Warehouse environments are RFID’s toughest critics:

Quick Fix: If tags are missed in high-traffic zones, lower the antenna height and increase gain slightly.

Cykeo’s Advantage: Their modular antennas allow gain adjustments via software, eliminating physical swaps during trials.

Takeaway: Choosing RFID antennas isn’t about specs—it’s about context. By aligning size and gain with your warehouse’s rhythm, you’ll turn tracking from a chore into a competitive edge.

Learn how to maintain fixed RFID readers in high-dust environments. Discover Cykeo’s dustproofing strategies, cleaning routines, and firmware updates for reliable performance.

MoreCandid insights into using RFID for enterprise laptop tracking—real projects, mistakes, shortcuts, and lessons from LA and Brooklyn.

MoreWondering whether RFID or barcodes are more cost-effective? This article compares the cost of RFID tags vs barcodes and helps you decide based on your business needs and budget.

MoreDiscover the best fixed RFID readers for healthcare equipment tracking. Learn how Cykeo’s HIPAA-compliant systems improve efficiency, disinfection compliance, and patient safety.

More