What key features should logistics and supply chain businesses look for in handheld RFID scanners?

For demanding logistics and supply chain environments, handheld RFID scanners must balance durability, performance, and integration capabilities. Here are the 7 critical features to prioritize:

1. Rugged Design for Harsh Environments

- Opt for IP67-rated scanners to withstand dust, drops, and water exposure in warehouses or outdoor yards.

- Reinforced casings protect against impacts during forklift operations or loading dock use.

2. Long Battery Life & Hot-Swappable Packs

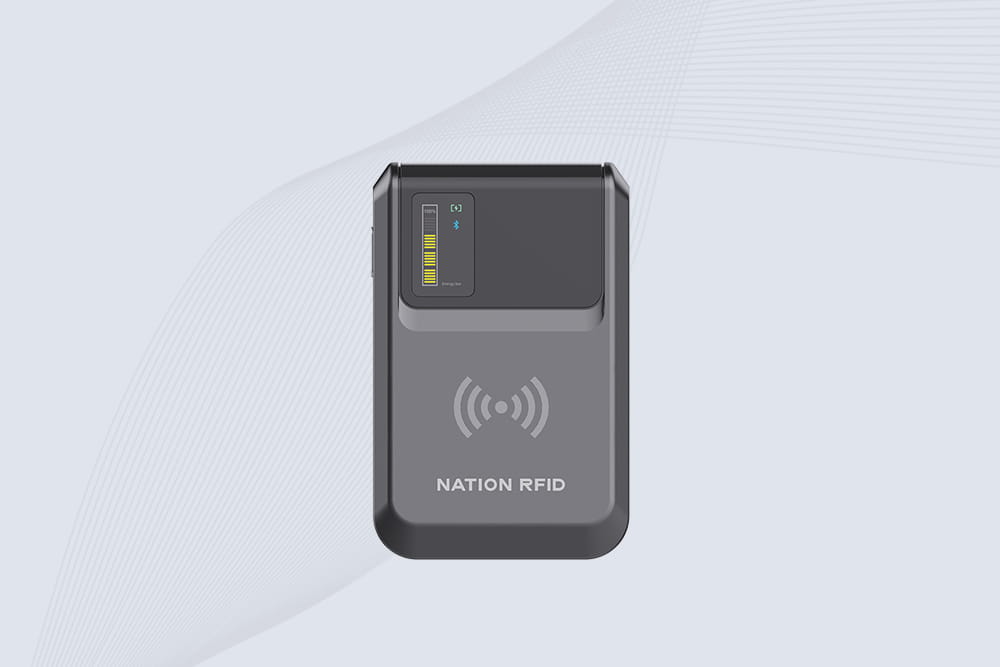

- Look for 10+ hours of continuous operation and swappable batteries to avoid downtime during shifts. For example, the CK-B2 RFID Handheld Reader’s dual-battery system ensures 24/7 readiness.

3. Extended Read Range & High Accuracy

- UHF RFID scanners with 6–10 meter read ranges capture tags on pallets or stacked crates without direct line-of-sight.

- Anti-collision algorithms process 500+ tags per second for high-density inventory checks.

4. Multi-Mode Scanning (RFID + Barcode)

- Hybrid scanners that read both RFID tags and barcodes streamline workflows. Warehouse teams can scan legacy barcoded items while transitioning to RFID.

5. Real-Time Data Syncing via Wi-Fi/Bluetooth

- Instant updates to WMS or ERP systems (e.g., SAP EWM) via Wi-Fi 6 or Bluetooth 5.0 eliminate manual data entry errors.

6. Ergonomic Design for All-Day Use

- Lightweight models (<500g) with pistol-grip or ergonomic handles reduce worker fatigue during 8-hour shifts.

7. Customizable Software & API Support

- Ensure compatibility with logistics platforms like Oracle SCM or Manhattan Associates through SDKs or REST APIs.

Pro Tip: Pair handheld scanners with fixed RFID readers at dock doors for hybrid tracking—mobile checks in aisles and automated scans at choke points.

Cykeo RFID IoT Solution Products R&D Manufacturer

Cykeo RFID IoT Solution Products R&D Manufacturer