How Cykeo RFID is Totally Changing Warehouse Management

125Tired of messy inventory and lost shipments? Try RFID! Real-time visibility, automated stocktaking, precise tracking—warehouse management just got a whole lot easier.

MoreAll RFID Product

If you’ve ever walked through a warehouse where items move faster than people can count, or managed an industrial site where assets vanish unless someone’s watching 24/7 — then you already understand the pain that ultra high frequency RFID quietly solves every day.

In the RFID industry, there’s a simple rule: the higher the frequency, the farther you can see — and the more precise you need to be. UHF, or ultra high frequency RFID, operates roughly between 860 MHz and 960 MHz, and it’s what makes large-scale, automated identification possible. But the technology itself isn’t “magic.” It’s the result of years of antenna design, signal tuning, and practical problem-solving done by integrators and engineers who’ve had to make it work in the real world.

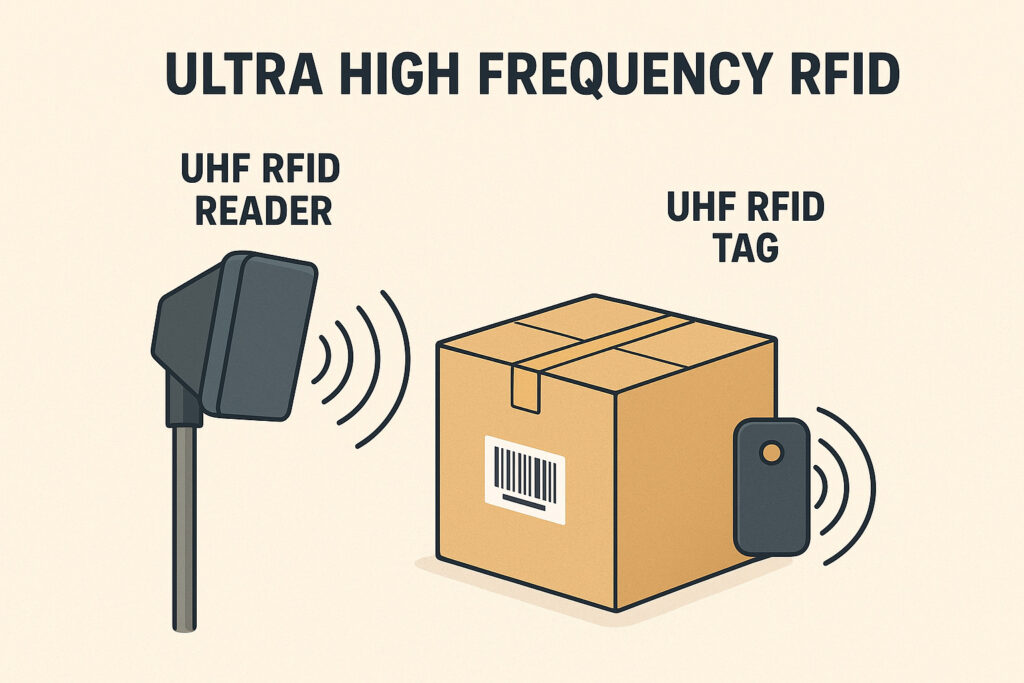

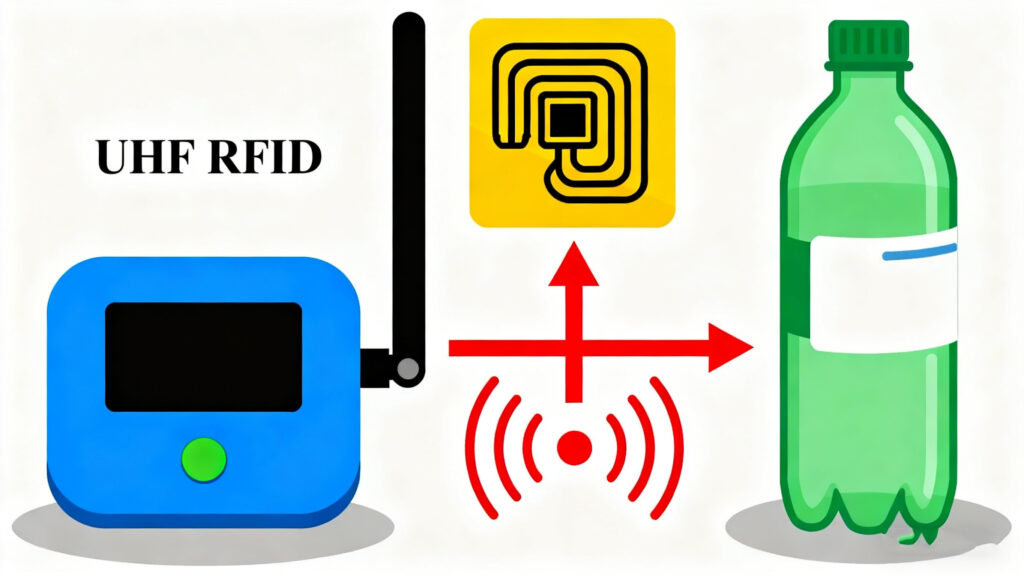

Every UHF RFID system is built around the same three pieces: a tag, a reader, and the software that connects them.

The tag carries a small chip and an antenna. When the reader sends out radio waves, the tag “wakes up,” harvests that energy, and reflects back its information. It doesn’t need a battery, it doesn’t need direct contact — just the right frequency and a bit of clean airspace between them.

Unlike low-frequency systems that rely on magnetic induction, UHF RFID works in the far-field region. That means it behaves more like a radio transmitter than a proximity sensor. The upside? You can read dozens or even hundreds of tags in a single sweep. The downside? Metal, water, and complex surroundings can turn that smooth wave into chaos.

That’s where good engineering comes in.

For solution providers, UHF RFID isn’t just about technical performance — it’s about scalability, integration, and economics.

So when you design or integrate an RFID solution today — whether for logistics, healthcare, retail, or manufacturing — UHF often ends up being the practical default. It’s the sweet spot between range, cost, and reliability.

Of course, any engineer who has deployed a UHF system knows the headaches that come with it.

The biggest challenge? Interference.

UHF signals hate metal surfaces. They also don’t play nicely with water, because water absorbs radio waves. That’s why a tag that works perfectly on a cardboard box can fail miserably when placed on a metal rack or a bottle of liquid detergent.

Solution providers typically work around this through a mix of antenna tuning, proper tag orientation, and shielding techniques. Sometimes, a small spacer layer between the tag and the metal surface is enough to restore performance. In more advanced cases, a specially designed on-metal tag or near-field UHF antenna may be required.

Then there’s regulatory tuning. Different regions of the world allocate slightly different UHF bands — for instance, 865–868 MHz in parts of Europe versus 902–928 MHz in North America. For integrators working on international deployments, that means frequency agility matters. Multi-band readers and tunable antennas are now common for this reason.

Look around a modern logistics hub and you’ll find UHF quietly doing its job everywhere — on pallets, forklifts, workstations, uniforms, even returnable containers.

In manufacturing, it’s used to track components through assembly lines. In healthcare, to monitor surgical instruments and prevent mix-ups. In retail, to count thousands of garments in a few seconds.

What makes UHF stand out isn’t the technology itself — it’s the consistency it brings to data collection.

When you can see every item moving in and out of your facility, in near real time, you can automate almost everything else on top of that: analytics, restocking, billing, security, compliance.

For RFID solution providers, that visibility is the product.

If you’re designing or deploying UHF systems, keep these real-world truths in mind:

UHF isn’t a plug-and-play miracle; it’s a finely tuned ecosystem. But when set up right, it delivers the kind of visibility and control that few other technologies can match.

Ultra high frequency RFID has become the backbone of modern tracking and identification systems — not because it’s the newest, but because it’s the most adaptable. For solution providers, it offers the perfect balance between range, cost, and flexibility.

It’s the frequency band that lets a warehouse see its inventory, a hospital find its equipment, and a logistics firm keep promises to its customers — all in real time.

So if you’re in the business of building RFID solutions, mastering UHF isn’t optional anymore. It’s the foundation that everything else stands on.

Cykeo CK-B9 UHF Bluetooth handheld RFID scanner features 12m UHF range, 200+ tags/sec scanning, IP67 rugged design for retail/warehouse/pharma. Supports Android SDK & real-time Bluetooth 5.0 transmission.

Cykeo CK-B4 UHF Handheld RFID Reader scanner delivers 1300 tags/sec reading, 30m UHF range, and 12-hour battery life. IP65 rugged design with barcode/NFC/ID scanning for retail/manufacturing/logistics.

Cykeo CK-B2L industrial UHF RFID handheld offers 10m range, 500 tags/sec scanning, Android 11 OS, and IP65 rugged design for retail/warehouse/manufacturing.

Cykeo CK-B3 industrial RFID Reader Handheld, terminal offers 2m read range, multi-protocol scanning (NFC/barcode/ID), Android 10 OS, and IP65 ruggedness for logistics/retail/manufacturing.

Tired of messy inventory and lost shipments? Try RFID! Real-time visibility, automated stocktaking, precise tracking—warehouse management just got a whole lot easier.

MoreCYKEO RFID USB scanner designed for developers and system integrators. This USB RFID scanner connects via Type-C, supports tag reading, writing, and data conversion, and integrates easily with custom software systems using demo tools and SDKs.

MoreCK-TP3BC RFID inventory tunnel system enables automated, hands-free batch inventory tracking on conveyor lines. Designed for fashion, wine, and electronics warehouses, with RESTful and native APIs for ERP, WMS, and IoT integration.

MoreCK-GTC5 RFID tool tracking system helps tool storage suppliers upgrade cabinets into intelligent tool control solutions. Ideal for prisons and military facilities, with open RESTful & native APIs, SDK support, and flexible integration of RFID read...

More