5 Hidden Costs of Cheap RFID Readers (& How to Avoid Them)

860Discover the 5 hidden costs of cheap RFID readers and learn how Cykeo’s high-performance RFID solutions save you money, improve efficiency, and ensure long-term ROI.

MoreAll RFID Product

Let’s be honest — UHF RFID technology isn’t new anymore, but it’s still one of those tools that quietly keep operations running smoother, especially in logistics, warehousing, and large-scale asset tracking. And for anyone working in RFID integration or solution design, knowing your way around a UHF RFID Sled Reader can make you look a lot smarter in front of clients.

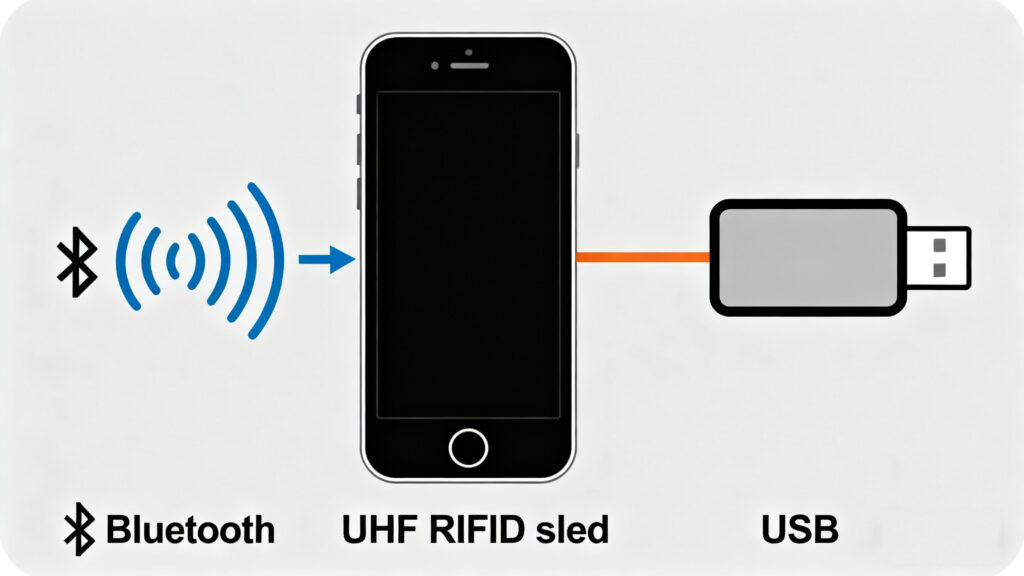

Think of it as a smart add-on for your phone or tablet. You slide your mobile device into the reader — it clicks in snugly — and suddenly your phone becomes a serious RFID scanner. The sled itself houses the antenna, handle, and power source, while your phone handles the brains — data processing, connectivity, and interface.

Most sled readers connect via Bluetooth or USB, depending on what the user prefers. Once paired, it can start reading hundreds (sometimes thousands) of tags per second. For teams in warehouses, retail stores, or hospitals, it’s a practical, mobile way to collect RFID data without lugging around a bulky handheld terminal.

The first thing any experienced integrator checks is compatibility. Can the sled actually work with the client’s existing RFID middleware or ERP system? And does it support common protocols like EPC Class 1 Gen 2 or ISO 18000-6C?

If the answer isn’t a clear yes, you’ll waste hours debugging something that should’ve worked out of the box.

Here’s where context matters. If the client’s staff moves around a lot — say, in a warehouse or on the retail floor — Bluetooth is convenient. But if they’re using it at a fixed workstation where stability matters, USB is safer and faster.

And of course, make sure it supports the operating systems they’re actually using. Android dominates, but some still run iOS or even Windows tablets in industrial setups.

Performance isn’t just about how far it reads — it’s how it performs under stress. Some sled readers can pick up tags from 30 meters away, others handle over a thousand tags per second. But numbers on a spec sheet don’t tell you if it’ll survive a drop on a concrete floor.

If your client’s using it in dusty warehouses or outdoor yards, you’ll want something with IP-rated protection (waterproof, dustproof, drop-resistant). Otherwise, you’ll be fielding repair calls every other month.

Here’s a detail that’s easy to overlook: battery runtime. Long shifts need a reader that won’t die halfway through a scan round. Good sleds can last an entire workday and charge quickly — some even support wireless charging, which is surprisingly useful when operators rotate equipment.

For solution providers, this part often makes or breaks a project. You’ll want hardware that offers a proper SDK or API, so your development team can integrate it smoothly into your client’s system. Pre-built demo apps are nice, but an open platform lets you build what you actually need — custom data filters, workflow triggers, or direct database sync.

Let’s break it down step-by-step — the way most integrators handle it in the real world:

A UHF RFID Sled Reader might look like just another peripheral, but for many businesses, it’s what connects field data with real-time visibility. For solution providers, understanding how to pick the right model — and explain why it fits — can turn an average project into a well-oiled system.

If you’re helping clients upgrade their RFID operations, take the time to test different sleds in real-world conditions. Numbers on spec sheets don’t tell the whole story — field experience does.

And if you ever need an extra pair of eyes on your integration plan or want help benchmarking devices, reach out. Sometimes a quick technical conversation saves weeks of trial and error.

Cykeo CYKEO-B9 UHF Bluetooth handheld RFID scanner features 12m UHF range, 200+ tags/sec scanning, IP67 rugged design for retail/warehouse/pharma. Supports Android SDK & real-time Bluetooth 5.0 transmission.

Cykeo CYKEO-B4 UHF Handheld RFID Reader scanner delivers 1300 tags/sec reading, 30m UHF range, and 12-hour battery life. IP65 rugged design with barcode/NFC/ID scanning for retail/manufacturing/logistics.

Cykeo CYKEO-B2 industrial UHF RFID handheld offers 10m range, 500 tags/sec scanning, Android 11 OS, and IP65 rugged design for retail/warehouse/manufacturing.

Cykeo CYKEO-B3 industrial RFID Reader Handheld, terminal offers 2m read range, multi-protocol scanning (NFC/barcode/ID), Android 10 OS, and IP65 ruggedness for logistics/retail/manufacturing.

Discover the 5 hidden costs of cheap RFID readers and learn how Cykeo’s high-performance RFID solutions save you money, improve efficiency, and ensure long-term ROI.

MoreLearn como programar RFID access control step by step: from reading card UIDs with Arduino to enrolling credentials in commercial controllers. Practical tips, common mistakes, and best practices for a secure system.

MoreLearn how RFID tags are reshaping industrial applications — from warehouse tracking to quality control. Practical insights, challenges, and lessons from real-world use cases.

MoreHow to block RFID signals in real scenarios. Learn practical shielding methods, what actually works, and how CYKEO tests RFID signal control.

More