Can Flipper Zero Read RFID? Let’s Get Real.

113Trying to use a Flipper Zero for RFID tasks? This no-nonsense guide explains its real-world capabilities, its hard limits, and when you truly need an industrial system.

MoreAll RFID Product

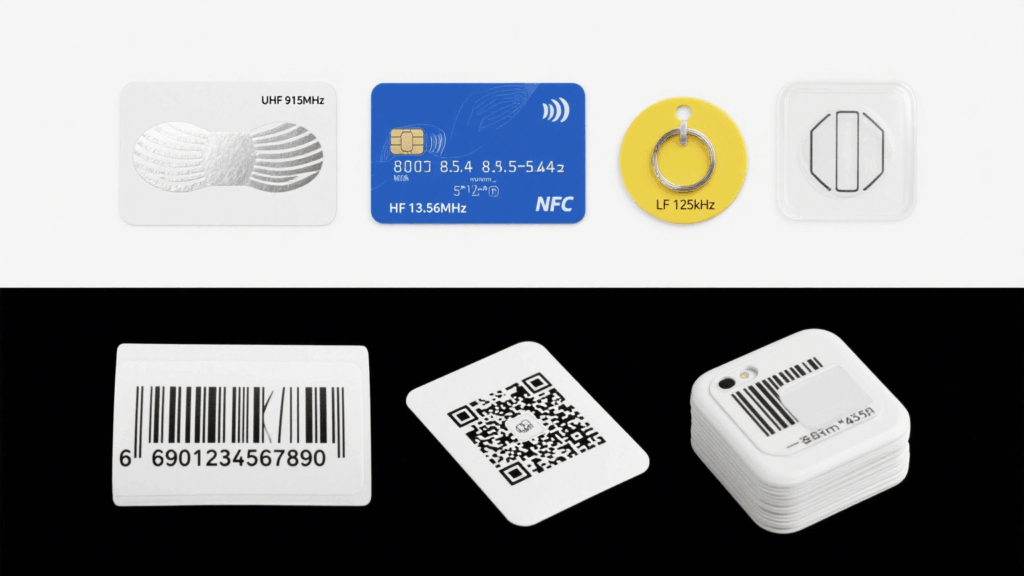

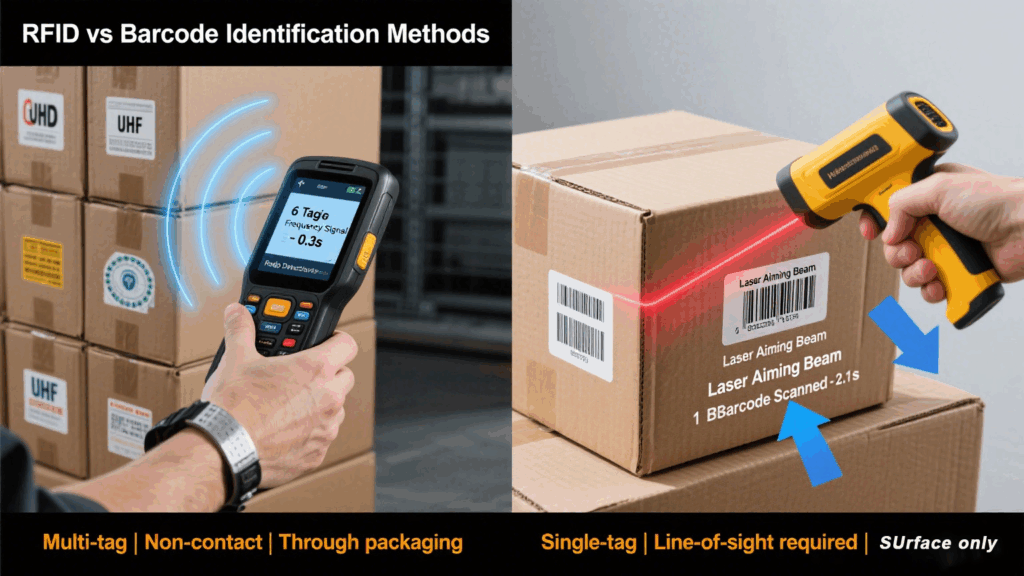

RFID (Radio Frequency Identification) and barcode technologies are two of the most commonly used automatic identification methods in modern supply chain and retail management. While both are used to identify and read data from physical items, they differ significantly in how they operate, their suitable application scenarios, and implementation costs.

In practical applications, each technology has its own advantages. The best choice depends on the specific business needs and budget.

The difference in how RFID and barcode systems read information directly impacts their operational efficiency:

| Feature | RFID | Barcode |

|---|---|---|

| Reading Method | Wireless, no line-of-sight required | Optical scan, line-of-sight needed |

| Reading Speed | Reads dozens of tags simultaneously | One tag at a time |

| Reading Distance | 10 cm to 10 meters (depending on tag) | 3–30 cm |

| Data Capacity | Several kilobytes, readable & writable | Very limited, product code only |

| Dirt Resistance | Can be embedded, waterproof/dustproof | Easily damaged or blocked by dirt |

If your business requires fast, high-volume tag reading, RFID is far more efficient. However, for individual product scanning and low-frequency tasks, barcode systems remain cost-effective and practical.

RFID systems involve higher initial costs in hardware, software, and system integration. Although RFID tag prices have decreased in recent years, they are still significantly more expensive than barcode labels. However, RFID offers long-term benefits by reducing labor, improving inventory efficiency, and minimizing errors.

| Cost Aspect | RFID | Barcode |

|---|---|---|

| Tag Cost | ¥0.5–¥2 (depending on frequency/packaging) | ¥0.01–¥0.05 |

| Scanner/Reader | Higher (requires RFID-enabled devices) | Low (standard barcode scanner) |

| System Integration | Custom APIs and middleware required | Quick setup with universal systems |

For mid-to-large-scale warehouses, manufacturing, or export businesses, RFID offers better long-term ROI despite higher upfront investments.

While RFID technology continues to evolve, it is unlikely to completely replace barcodes in the short term:

For companies currently making procurement decisions, here are some practical recommendations:

By evaluating your workflow requirements, hardware compatibility, and budget planning, you can choose the right technology to support your digitalization and intelligent operations journey.

CYKEO Passive RFID Tags are made for wet and high-humidity environments where standard labels do not last. This rfid passive tag is often used around liquids, chemicals and temperature changes, providing stable reading distance and long data life for industrial tracking.

CYKEO CK-BQ1504 Metal RFID Tags is a compact anti-metal UHF RFID solution built for direct mounting on metal surfaces. With stable 8-meter read range, Ucode-8 chip, and long data retention, this rfid metal tag fits tools, containers, automotive parts, and industrial asset tracking.

CYKEO CK-BQ7020 On-Metal RFID Tags are designed for reliable tracking on steel and metal surfaces. Built with an FR4 epoxy body and industrial-grade chips, these On-Metal RFID Tags deliver stable performance, long data life, and chemical resistance, making them a dependable RFID anti-metal tag for harsh environments.

The CYKEO CK-BQ6025 Anti-Metal RFID Tag is built for metal surfaces where standard tags fail. Designed for long-range performance, harsh environments, and stable data retention, this Anti-Metal RFID Tag is ideal for industrial assets, containers, and equipment tracking using on metal RFID tags.

Trying to use a Flipper Zero for RFID tasks? This no-nonsense guide explains its real-world capabilities, its hard limits, and when you truly need an industrial system.

MoreLearn how RFID scanners communicate with tags, their core components, and the science behind wireless data capture in logistics, retail, and healthcare.

MoreDiscover the key differences between handheld RFID and barcode scanners—speed, accuracy, durability, and which suits your workflow.

MoreRFID asset tracking in the education sector enables digital management of books, computers, multimedia equipment, and other assets through efficient identification and real-time location tracking. It improves management efficiency, prevents asset ...

More