RFID Antenna Arrays in Retail: Boost Inventory Accuracy and Slash Stock Errors

1150Discover how RFID antenna arrays transform retail inventory management—reduce stockouts, improve accuracy, and streamline audits.

MoreAll RFID Product

In today’s increasingly competitive global trade environment, enterprises are urgently seeking solutions for supply chain optimization, inventory accuracy, and production efficiency. Traditional barcode systems are gradually proving inefficient when handling massive quantities of goods and complex workflows. RFID tagging systems, leveraging advanced radio frequency identification technology, offer an accurate, efficient, and intelligent management solution, emerging as a key innovation for modern enterprises.

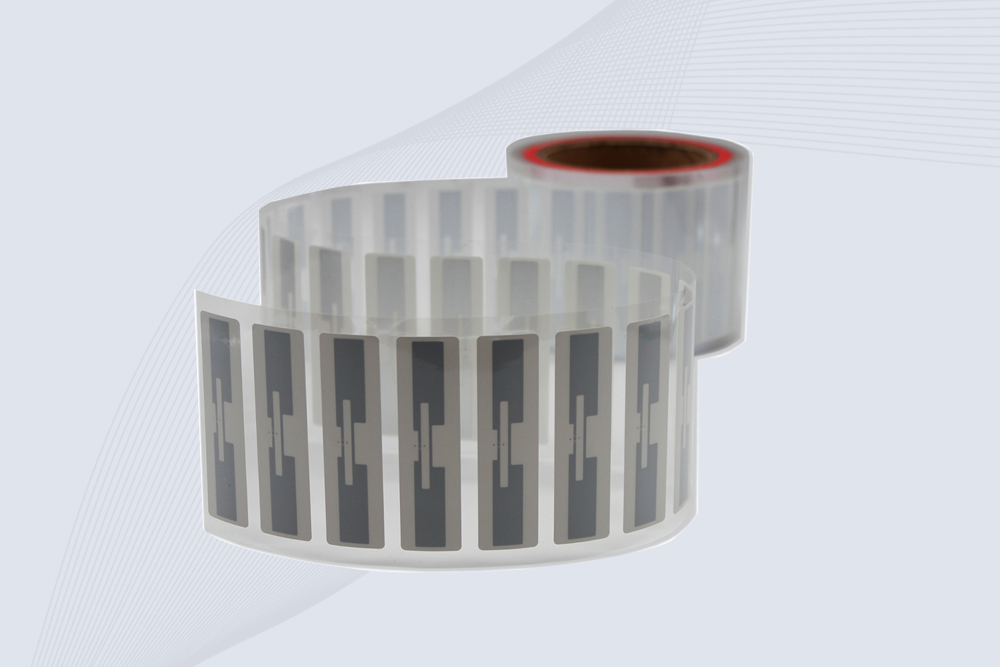

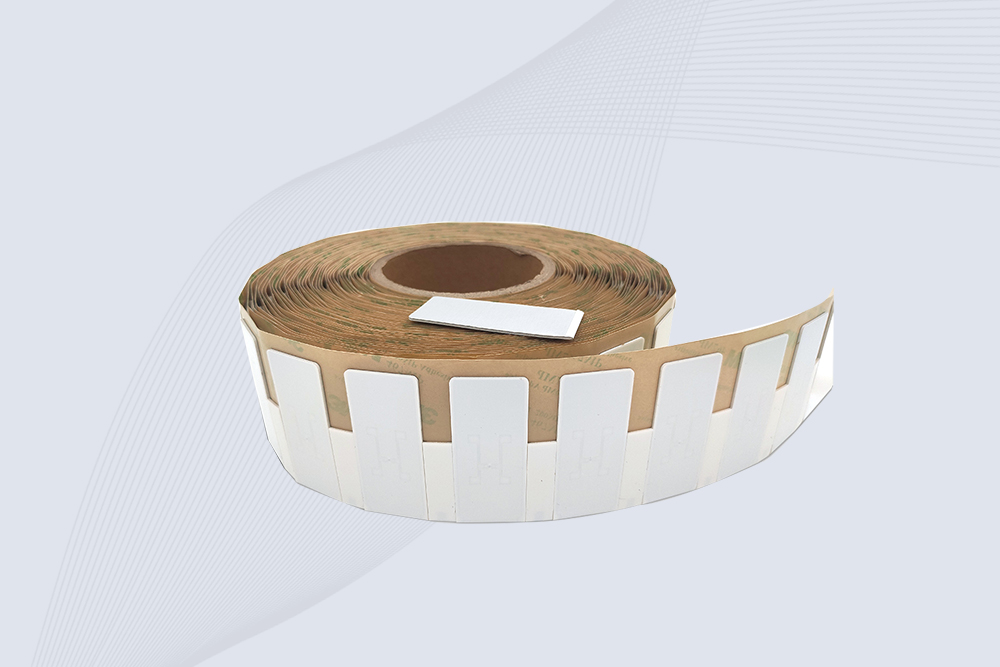

RFID tagging system consists of RFID tags, readers, antennas, and data management software. Each RFID tag contains a chip and antenna that stores unique identification, specifications, production details, and more. The reader communicates with tags via radio signals to read and write data, while the software processes, stores, and analyzes the collected information. Supporting long-distance, batch, and contactless recognition, RFID systems offer far greater accuracy and efficiency compared to traditional barcode systems—even in harsh environments.

When managing procurement, warehousing, transportation, and sales of large volumes of goods, barcode systems often reveal several issues. Manual scanning is time-consuming and prone to bottlenecks during peak periods. Barcodes can be damaged or dirtied, leading to errors that affect inventory accuracy. They also lack real-time tracking capabilities. RFID systems solve these challenges by automating item identification and management, improving supply chain responsiveness, lowering operational costs, and enhancing market competitiveness.

Efficient Automation: RFID can simultaneously read hundreds of tags, significantly reducing time for stocktaking and goods handling. For example, inventory checks that once took days can now be completed in hours.

Accurate Data Capture: RFID tags store large amounts of data and are highly resistant to damage. With read accuracy exceeding 99%, they ensure data integrity and prevent business loss due to misinformation.

Real-Time Tracking: Deploying readers at key points allows companies to monitor the location and status of goods across production, storage, and transportation.

Scalability: RFID systems can flexibly scale in terms of tag volume, reader coverage, and software functions to adapt to businesses of various sizes and needs.

Technical Capability & Product Quality: Opt for vendors with proven RFID development experience. Ensure products meet international standards, offering features such as waterproofing, heat resistance, and anti-interference.

System Compatibility: Make sure the RFID system integrates seamlessly with your existing ERP, WMS, and other systems for real-time data exchange.

Customization Services: Choose a provider that offers tailored solutions to suit your unique workflows and industry requirements.

After-Sales Support: Reliable vendors should offer full lifecycle services—from installation and training to maintenance and software updates—to ensure stable long-term operation.

A garment trading company integrated RFID tagging throughout its production process—applying tags to each item during manufacturing. This enabled full tracking from raw material storage to finished goods shipping. Inventory counting time dropped by 80%, while inventory accuracy rose from 85% to 98%. Stockouts and overstocking were significantly reduced. Customers could track logistics in real time through the company’s website, leading to a 20%+ increase in annual sales.

As global trade embraces digital transformation, RFID tagging systems are becoming essential tools for enterprises to improve operational management and enhance competitiveness. Choosing the right RFID solution can help businesses reduce costs, increase efficiency, and gain an edge in today’s fast-paced market.

CYKEO Passive RFID Tags are made for wet and high-humidity environments where standard labels do not last. This rfid passive tag is often used around liquids, chemicals and temperature changes, providing stable reading distance and long data life for industrial tracking.

CYKEO CK-BQ1504 Metal RFID Tags is a compact anti-metal UHF RFID solution built for direct mounting on metal surfaces. With stable 8-meter read range, Ucode-8 chip, and long data retention, this rfid metal tag fits tools, containers, automotive parts, and industrial asset tracking.

CYKEO CK-BQ7020 On-Metal RFID Tags are designed for reliable tracking on steel and metal surfaces. Built with an FR4 epoxy body and industrial-grade chips, these On-Metal RFID Tags deliver stable performance, long data life, and chemical resistance, making them a dependable RFID anti-metal tag for harsh environments.

The CYKEO CK-BQ6025 Anti-Metal RFID Tag is built for metal surfaces where standard tags fail. Designed for long-range performance, harsh environments, and stable data retention, this Anti-Metal RFID Tag is ideal for industrial assets, containers, and equipment tracking using on metal RFID tags.

Discover how RFID antenna arrays transform retail inventory management—reduce stockouts, improve accuracy, and streamline audits.

MoreExplore RFID Anti-Metal Tags—their principles, types, and applications—from factories to data centers, with real-world lessons and pitfalls.

MoreEnterprise-grade 4-port UHF RFID fixed reader with R2000 chipset, RESTful API, Java/C# SDK, and IP67 housing. Designed for flexible system integration into cabinets, doors, inventory, and payment solutions.

MoreLearn how to streamline healthcare asset tracking with handheld RFID scanners. Discover best practices for inventory management, compliance, and reducing equipment loss.

More