How to Make an RFID Reader Antenna: Why We Stopped Building Them In-House

Early on, we faced a hardware integration challenge. A client needed a custom-shaped UHF RFID reader, and the off-the-shelf antennas wouldn’t fit the industrial design. So, like many engineers, we asked: can we figure out how to make an RFID reader antenna ourselves? What followed was a months-long deep dive that ultimately taught us one core lesson: unless you’re an antenna design specialist, this is a battle you’re better off not fighting. Here’s why.

The Core Misconception: It’s Not an Amplified Tag Antenna

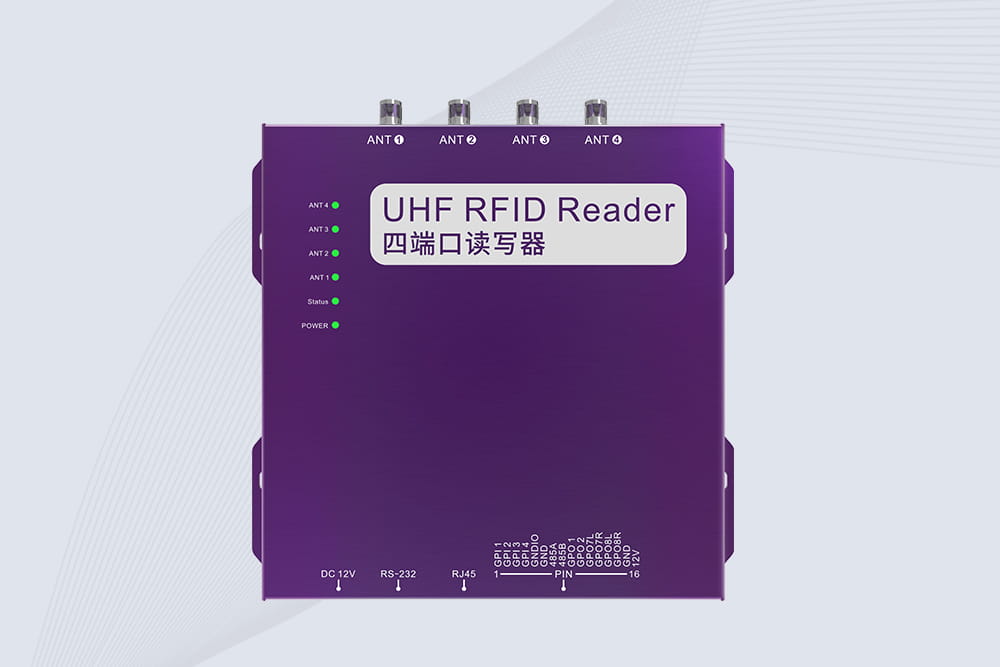

The first instinct is to think of a rfid reader antenna as a bigger, more powerful version of a tag antenna. That’s wrong. A tag antenna is designed to be a simple, cheap, matched load for a single chip. A reader antenna is a precision instrument. It must have a consistent, known radiation pattern (like circular polarization), operate efficiently across a wide bandwidth (e.g., the entire 860-960 MHz band), and present a perfect 50-ohm impedance to the reader’s delicate RF output stage. Get this wrong, and you can permanently damage the reader.

The Design Gauntlet: Simulation, Substrates, and Tuning

Here’s what the real process of trying to make a DIY UHF reader antenna involves:

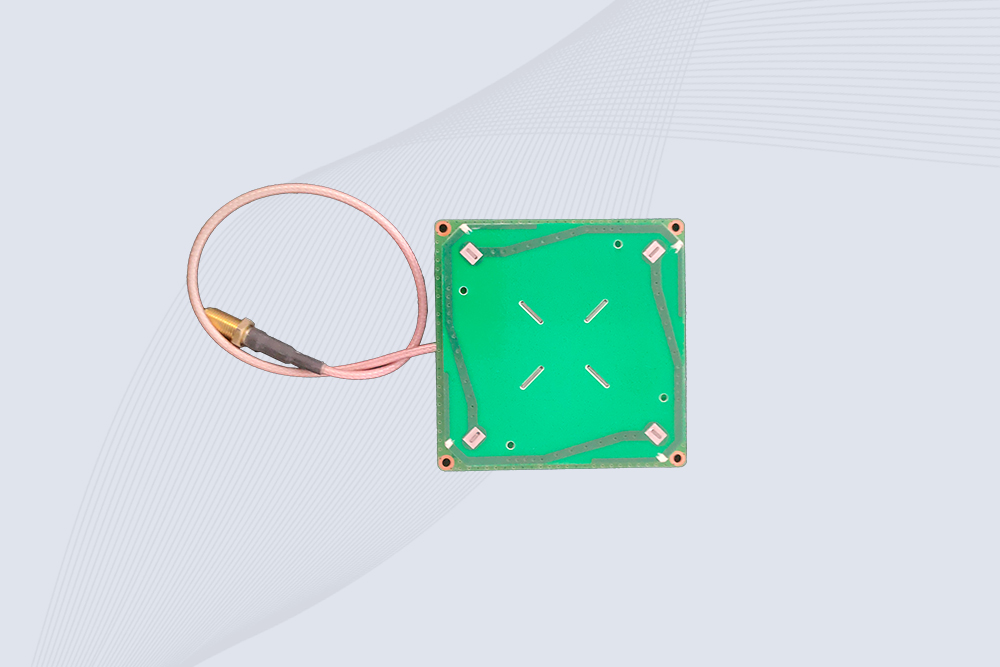

- EM Simulation is Non-Negotiable: You start in software like CST or ANSYS HFSS. You model a patch antenna, define your substrate (like Rogers 4350B for low loss), and simulate for days. You’re chasing key metrics: a wide S11 bandwidth, a clean axial ratio (for circular polarization), and a stable gain pattern. A single-digit percentage change in your substrate’s dielectric constant throws everything off.

- The Fabrication Precision Problem: You send your design to a PCB fab house. The antenna arrives. You measure it with a Vector Network Analyzer (VNA). The resonant frequency is 20 MHz off. Why? The fab house’s etching process has a tolerance. The copper thickness is slightly different. The laminate’s Dk (dielectric constant) has a manufacturing variance. You’re now in the iterative loop: tweak the design, pay for a new prototype, wait, and test again.

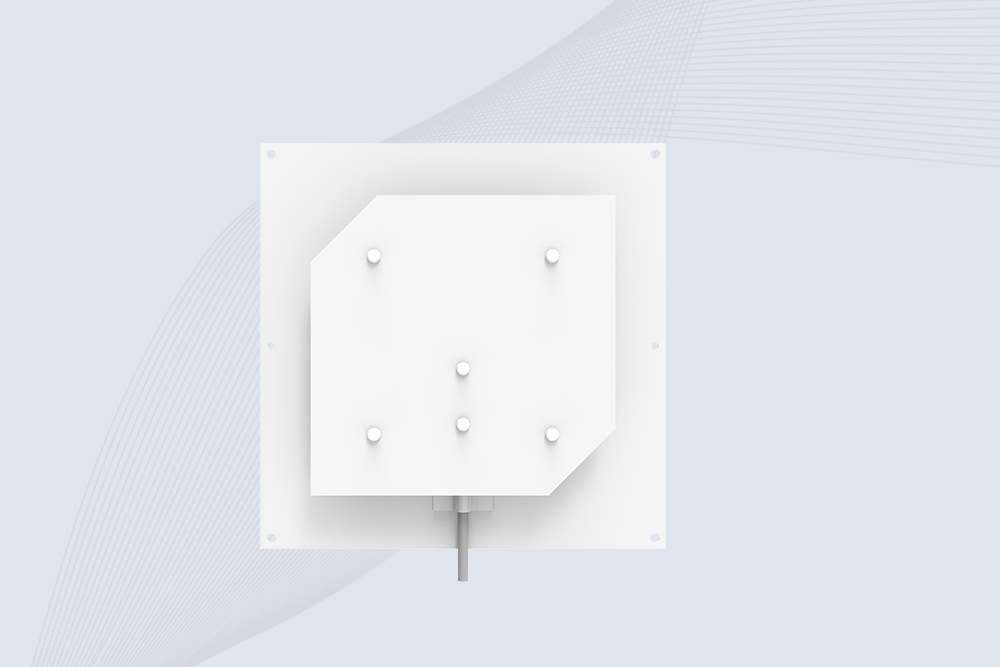

- The Housing is Part of the Antenna: You can’t just put this fragile PCB in a plastic box. The housing’s material and distance from the radiating element drastically affect performance. Designing the radome (the protective front cover) is its own RF challenge. It must be RF-transparent at the right thickness.

The “It Works” vs. “It Works Reliably” Chasm

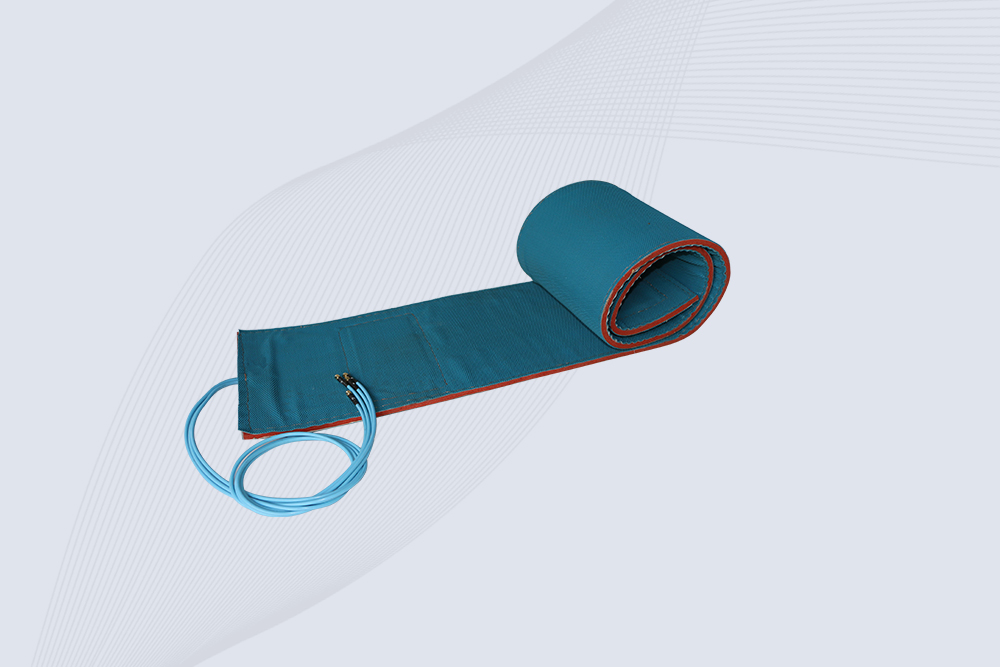

After several spins and thousands of dollars in simulation licenses, prototype fees, and VNA time, you might get a working unit. It reads tags in your lab. But then you build ten more. Their performance varies. One has a 5-degree narrower beamwidth. Another’s axial ratio is poor, making it sensitive to tag orientation. This is the reality of DIY vs. commercial reader antennas – consistency is everything in a professional deployment.

Furthermore, a commercial antenna is tested for durability (IP rating), temperature cycling, and UV resistance. Your homemade antenna will fail in the field, guaranteed.

Why We Source, Not Build

We learned that our core expertise is in integrating RFID systems and solving business problems, not in becoming a world-class antenna fab house. The economic equation is simple: the engineering hours, specialized software costs, and testing equipment needed to produce one reliable antenna design far exceed the cost of buying a perfectly engineered, mass-produced, and tested unit from a dedicated manufacturer.

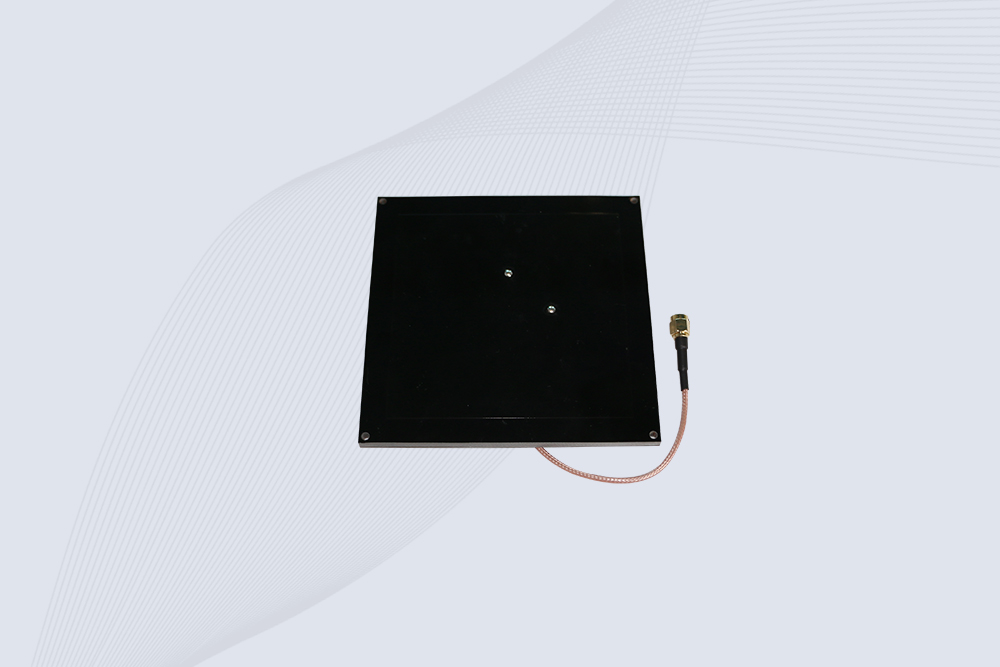

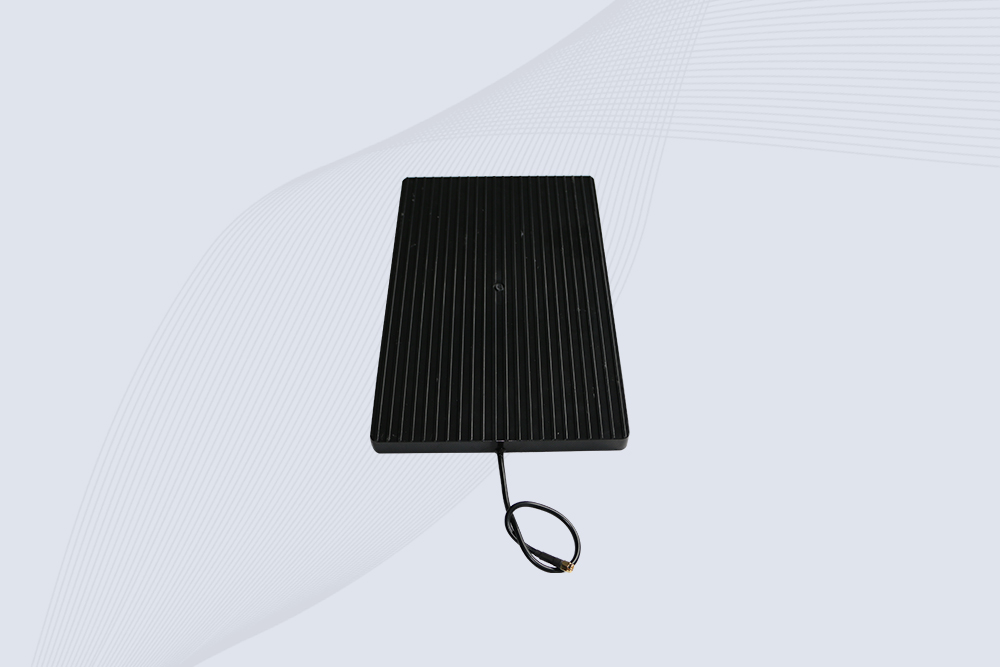

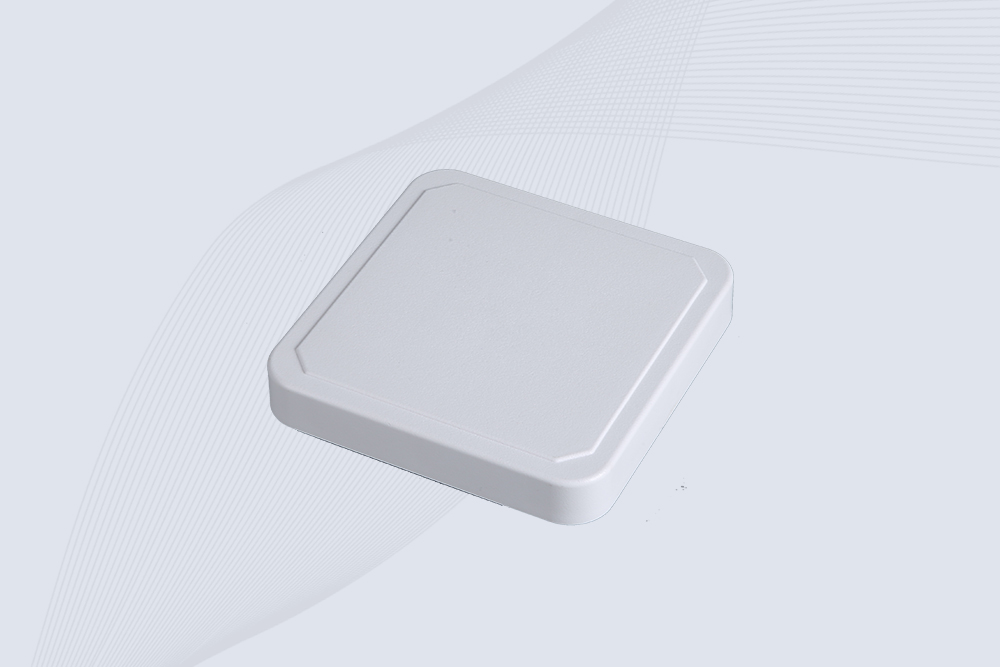

At CYKEO, we now partner with leading antenna producers. We select from their portfolios based on rigorous criteria: gain patterns for specific use cases (wide portal vs. focused tunnel), ruggedization for environments (warehouse, freezer, washdown), and connector types. We then test these selected antennas in real-world scenarios with our readers and tags to guarantee system-level performance.

So, if you’re asking how to make an RFID reader antenna as an academic exercise or for a one-off art project, go for it—you’ll learn a ton about RF engineering. But if you are building a system for asset tracking, inventory management, or any commercial application, the only sane answer is to buy a professionally designed antenna. It saves time, money, and ensures your entire RFID investment rests on a reliable, high-performance foundation. We learned this the hard way so you don’t have to.

RFID Antennas Recommendation

Cykeo RFID IoT Solution Products R&D Manufacturer

Cykeo RFID IoT Solution Products R&D Manufacturer