Attendance RFID Card Reader For Enterprise Attendance Management

455Attendance RFID Card Reader has become a popular choice for optimizing attendance systems in modern enterprises

MoreAll RFID Product

When people start comparing RFID hardware, they often find themselves overwhelmed by similar-looking specs. Many modules claim long reading ranges, high sensitivity, or “industrial performance.” But once the system leaves the lab and lands in a factory, a warehouse, or a retail stockroom, the differences become very noticeable. So, let’s break down what really matters when choosing a UHF RFID Module—and where the CK-M4L fits into this picture.

On paper, most modules look almost interchangeable. But in real environments, RF behavior becomes far more complex. Metal racks, stacked items, and dense tag clusters all introduce signal reflections and multi-path interference. This is where a well-designed RF front end and tuned algorithms start to show their value.

A good module doesn’t just read far—it reads steadily. Meaning the read rate and accuracy don’t jump up and down depending on the environment. Many engineering reports point out that modules built with optimized RF circuits can maintain much more stable EPC capture even in harsh settings.

Moving on, communication reliability is another area that people often underestimate. UART or USB looks simple enough, but once the device starts sending bursts of thousands of EPCs, weak firmware becomes obvious. Some modules choke under continuous load, lose data, or slow down.

A solid UHF RFID Module should process and transmit tag data smoothly for hours—or days—without crashing. That’s usually the difference between something that works in a demo and something that survives real deployment.

Now, here’s another practical issue: heat. Continuous high-power reading naturally warms up the RF board. If the internal design isn’t optimized, the module may throttle or drift. And if that happens, your read accuracy will start acting unpredictably.

Industrial-grade modules usually include thermal protection and adaptive power control. These small engineering details make a big difference over long working cycles.

In more advanced systems—like smart cabinets, POS stations, or compact terminals—modules often need to switch between several antennas. If the switching pattern is random or slow, tag blind spots become a real problem.

Research suggests that deterministic timing helps the module capture tags more evenly across all zones. This matters a lot when you’re scanning the same area repeatedly and need consistent results.

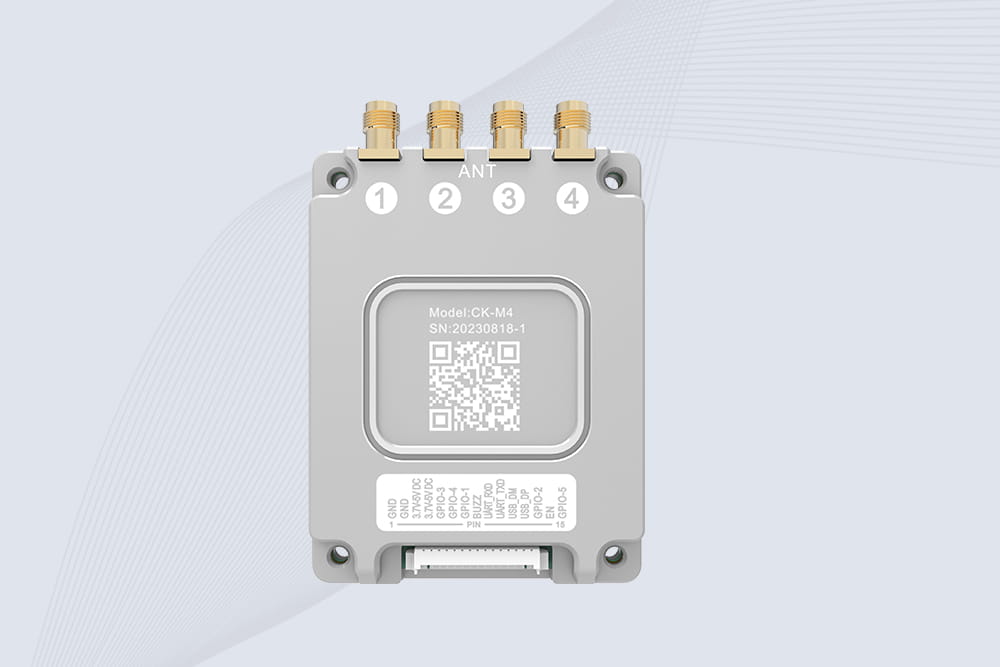

For users looking for a compact but reliable solution, the CK-M4L UHF RFID Module is a good reference point. It’s designed for devices such as handhelds, smart cabinets, POS terminals, and embedded systems where space is limited.

What stands out is how stable its RF behavior is even near metal structures or in dense-tag conditions. It maintains fast EPC reading, keeps communication smooth, and gives developers enough flexibility through adjustable power and well-structured interfaces. In short, it solves the common pain points you meet when trying to integrate a module into actual equipment.

At the end of the day, you’re not just choosing specs—you’re choosing stability. A trustworthy UHF RFID Module should offer predictable RF behavior, reliable data transmission, sensible heat control, and steady accuracy across different environments.

When these fundamentals are in place, the rest of the system becomes easier to build and maintain. And more importantly, the solution becomes something you can rely on long-term, not just something that reads well in a controlled test.

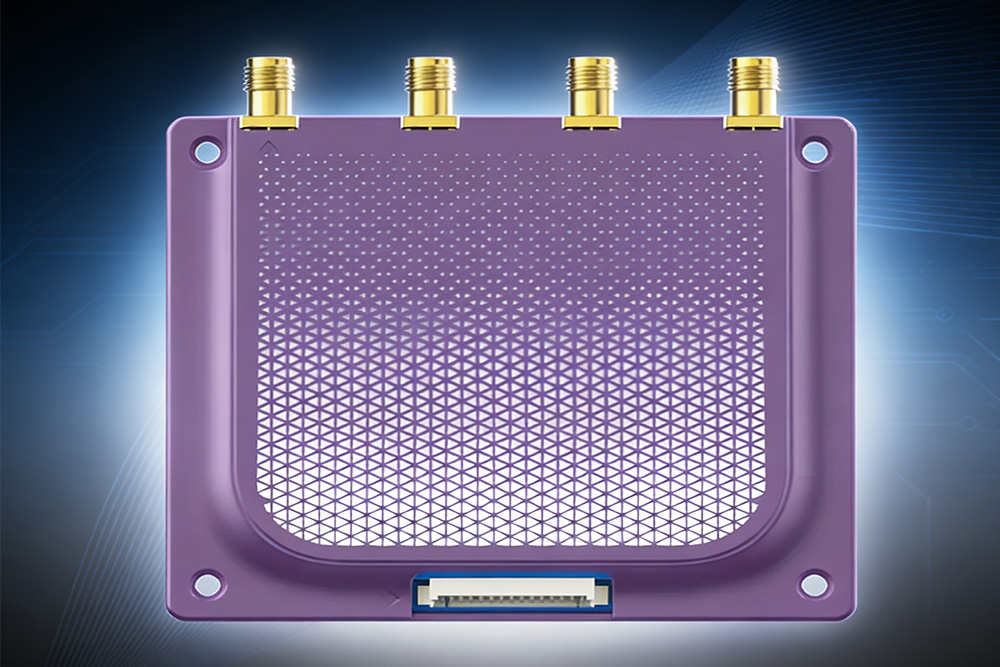

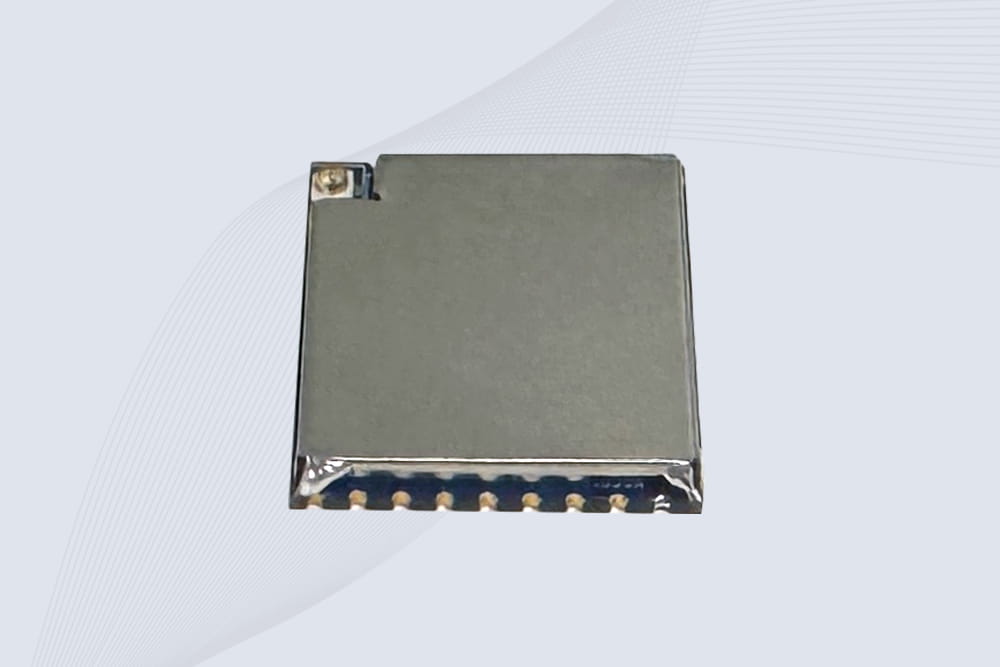

CYKEO Embedded RFID Modules are designed for compact industrial and IoT devices that require stable UHF performance. These UHF RFID Modules support global protocols, flexible power control, and reliable multi-tag reading for smart cabinets, production lines, and asset tracking systems.

CYKEO Embedded RFID Module is built for compact IoT and industrial devices that need stable UHF performance. This UHF module supports global protocols, low power operation, and reliable multi-tag reading for smart lockers, production lines, and always-on RFID systems.

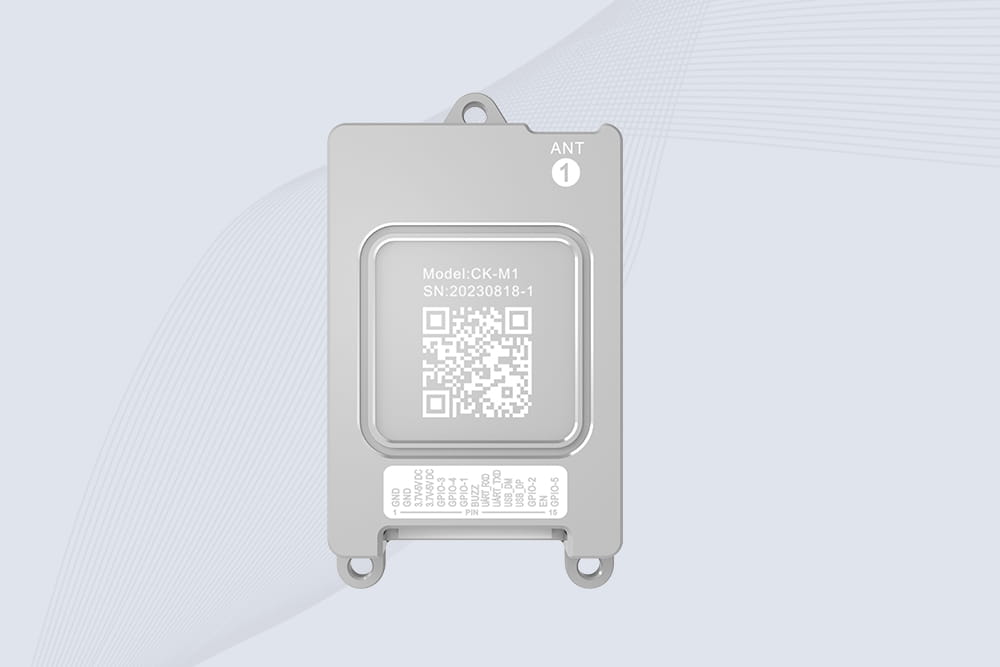

CYKEO CK-M1 drone rfid module is a compact UHF RFID reader module designed for drones and UAV platforms. It supports long-range aerial scanning, fast multi-tag reading, and stable performance in wind, vibration, and outdoor environments.

CYKEO CK-M4 RC522 RFID Module is an industrial-grade UHF RFID reader with 4 ports, supporting ISO, EPC, and GB protocols. High-speed, accurate reading for IoT, automation, and warehouse applications.

Attendance RFID Card Reader has become a popular choice for optimizing attendance systems in modern enterprises

MoreSetting up your system? We answer 'do RFID readers require antenna' and explain why this component is critical for any functional RFID setup.

MoreLearn how to position RFID reader modules for maximum coverage and accuracy in warehouses, retail stores, and manufacturing facilities. Avoid common mistakes with our guide.

MoreGet a clear answer to what is a RFID antenna. Learn how this hardware enables wireless communication in RFID systems for access control, tracking, and inventory.

More