Can Any RFID Reader Read Any Tag? Let’s Kill This Myth Right Now.

23Can any RFID reader read any tag? Absolutely not. Frequency, protocol, and regional standards kill "universal" compatibility. Here's what actually works and why.

MoreAll RFID Product

From package tracking to asset management, RFID tags are everywhere. But how do these compact RFID tags achieve precise identification? And how should you choose the right RFID tag for your needs? This article takes Cykeo RFID cable tie tag as example to give you in-depth understanding.

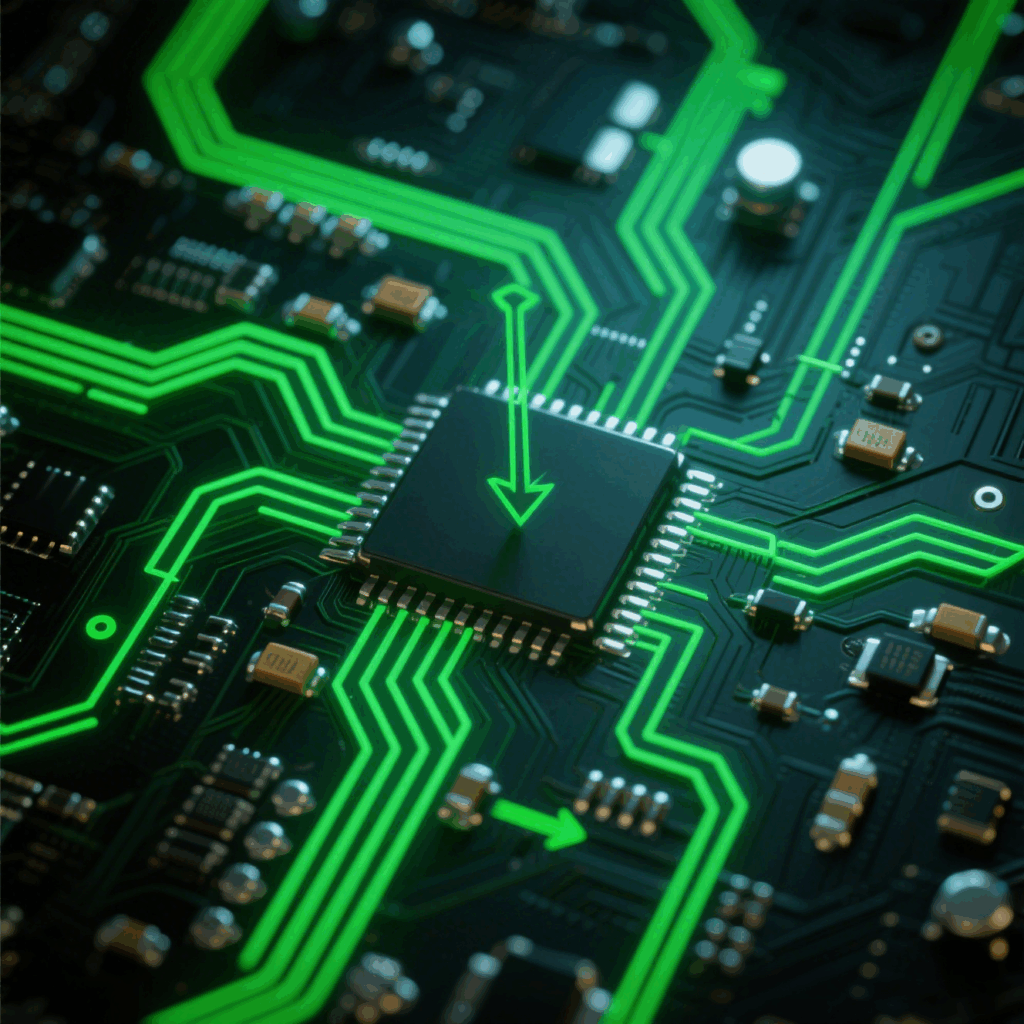

The core operating principle of RFID tags is based on the interaction of radio frequency (RF) signals to enable information exchange. The process can be broken down into three key steps: signal transmission, energy harvesting, and data communication.

RFID reader emits radio frequency signals through its antenna, generating an electromagnetic field in the surrounding area. In the case of Ultra High Frequency (UHF) RFID system, the operating frequency typically ranges from 860 to 960 MHz. This electromagnetic field can cover distance of several meters. When object with attached RFID tag enters this field, the tag receives the signal.

Passive RFID tags do not have built-in power source. When they receive the radio frequency signal from the reader, the tag’s antenna interacts with the electromagnetic field to generate a small induced current through electromagnetic induction. This current is then converted into a direct current (DC) voltage by rectifier circuit, which powers the tag’s chip. This process is similar to how solar panel collects light energy and converts it into electricity, effectively “waking up” the tag and enabling it to operate.

Once activated, the tag modulates its stored information—such as its electronic product code—by altering the impedance of its antenna. This modulation enables the tag to transmit data back to the reader using method known as backscatter. The reader receives the reflected signal, then demodulates and decodes it before sending the data to the backend system. The entire process is akin to “wireless conversation” between the tag and the reader.

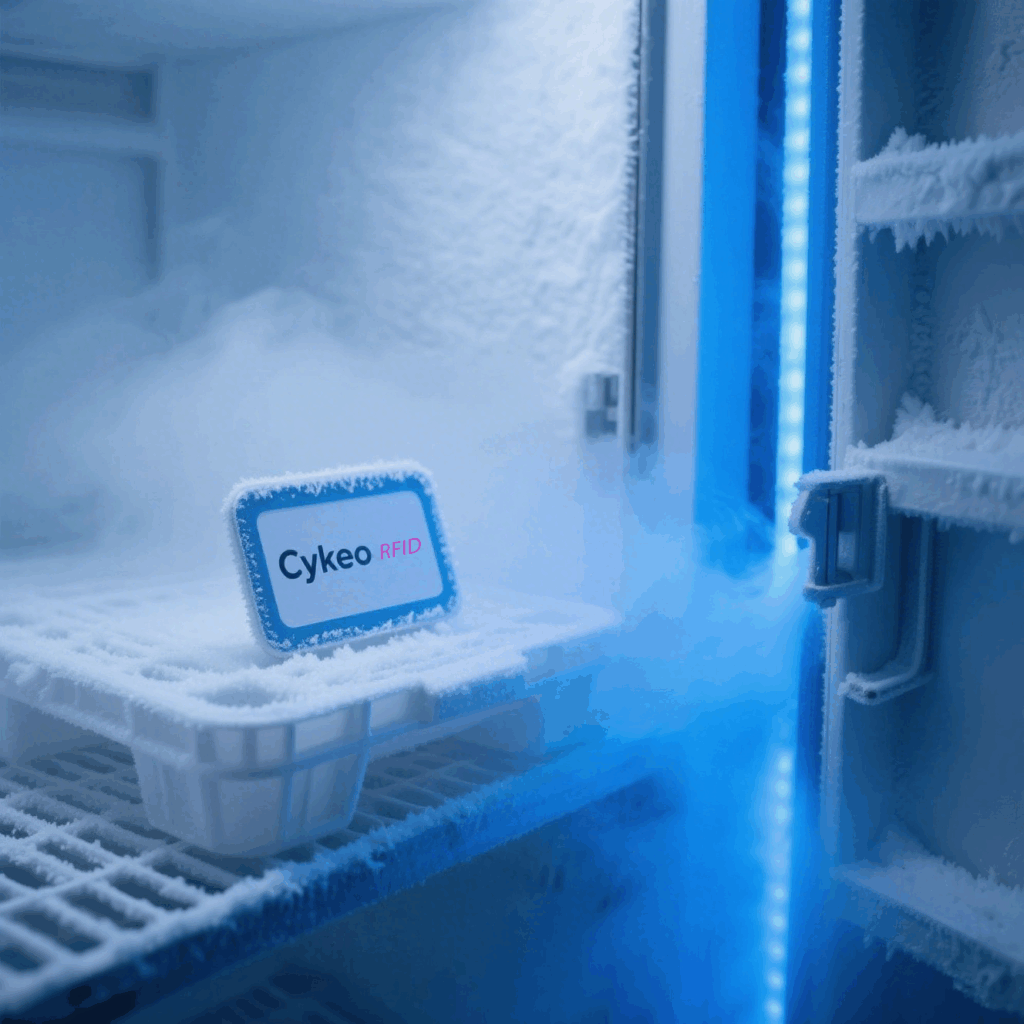

Selecting the appropriate RFID tag requires comprehensive consideration of factors such as the application scenario, environmental conditions, and performance requirements. Taking Cykeo RFID cable tie tag as example, it demonstrates unique advantages in specific use cases.

Different industries have distinct RFID tag requirements. In the power and telecommunications sectors, numerous cables need long-term and stable identification. Cykeo RFID cable tie tag combines the traditional cable tie function with RFID technology, allowing it to be directly fastened onto cables. It is suitable for complex environments such as outdoor settings and underground pipelines. Personnel can quickly read information like cable model and installation year through reader, significantly improving inspection efficiency.

Environmental factors directly affect the lifespan and performance of RFID tags. Cykeo RFID cable tie tags use a high-strength engineering plastic housing with an IP67 protection rating, making them waterproof and dustproof. They can withstand extreme temperatures ranging from -40°C to 85°C. Whether in damp underground cable trenches or high-temperature industrial workshops, these tags operate reliably, preventing damage or read failures caused by environmental conditions.

The Rfid tag operating frequency, read range, storage capacity, and other parameters need to align with actual requirements. Cykeo cable tie tags use the Ultra High Frequency (UHF) band, with read range of up to 5 meters, making them suitable for rapid scanning across large cable areas. Equipped with a high-capacity chip capable of storing 2KB of data, they meet the full lifecycle information recording needs of cables. Additionally, the tags support fast reading speeds of over 50 tags per second, greatly improving inventory efficiency.

The difficulty of installation directly affects deployment costs and efficiency. Cykeo RFID cable tie tags feature a self-locking strap design that requires no additional tools and can be installed by a single person. The strap tension is adjustable to ensure a tight fit between the tag and the cable. Compared to traditional adhesive labels, this design is simpler to install and less likely to fall off, thereby reducing maintenance costs.

As their unique operating principle, RFID tags enable efficient and precise automatic identification. When choosing rfid tag, considering the application scenario, environment, and performance requirements is essential. Cykeo RFID cable tie tags demonstrate strong adaptability and practicality in these respects. With ongoing technological advancements, RFID tags will play increasingly important role across various industries. If you are looking for reliable cable identification solution, Cykeo RFID cable tie tags are worth closer look.

Can any RFID reader read any tag? Absolutely not. Frequency, protocol, and regional standards kill "universal" compatibility. Here's what actually works and why.

MoreRFID asset tracking in the education sector enables digital management of books, computers, multimedia equipment, and other assets through efficient identification and real-time location tracking. It improves management efficiency, prevents asset ...

MoreNeed to know how to read RFID tags? Follow this practical guide covering tag types, reader selection, and setup steps for a working RFID system.

MoreIf your RFID gate access control system is slowing down vehicles, it’s usually a configuration, reader, or logic issue — not the technology itself. Learn practical tips to optimize reader placement, access rules, and detection range for smooth, re...

More