Submit your request to us

We will contact you as soon as possible.

All RFID Product

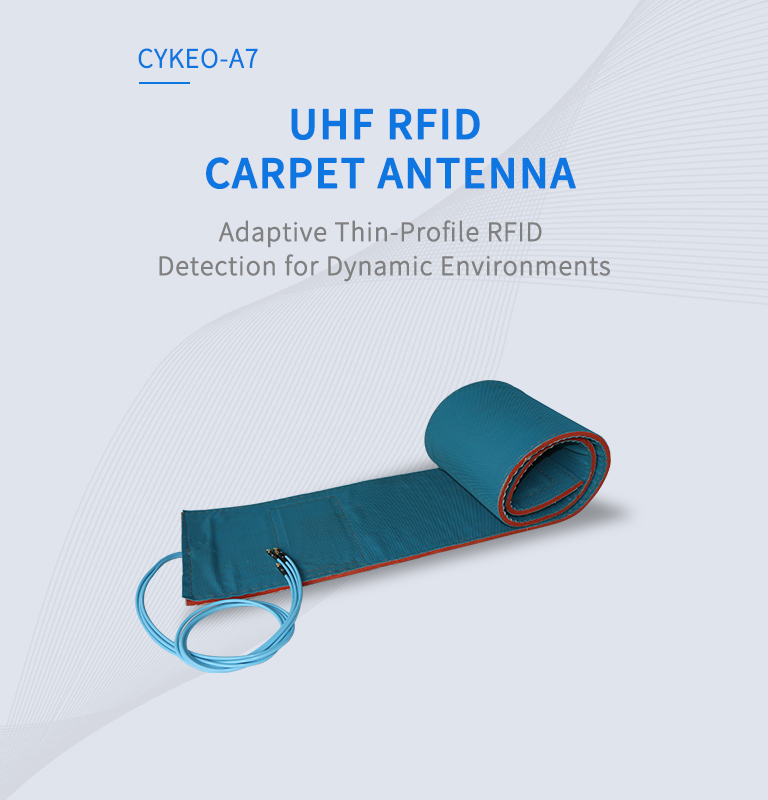

CYKEO-A7

Adaptive Thin-Profile RFID Detection for Dynamic Environments

✔️ Covers 840–960MHz Wide Frequency

✔️ Read Curved Surfaces with 98% Accuracy

✔️ 0.8mm More Easy Bending and Placement

CYKEO-A7 7dBi Flexible RFID Antenna is ultra-thin at 0.8mm, making it easy to place on curved or moving surfaces. It keeps reads accurate up to 98% and works from -40℃ to 85℃. Perfect for tracking medical gear, securing retail shelves, wrapping pallets, or monitoring automotive parts.

Main Specifications

Physical Parameters

Developer Support

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

Start by cleaning the area with alcohol and, on metal, add the 0.5mm spacer to avoid RF loss. Use the built-in adhesive for temporary setups or conductive epoxy for permanent fixes on materials like ABS or PVC. When bending, keep at least a 3mm radius—tighter bends can cut gain. For pipes or cylinders, wrap the antenna lengthwise instead of around to keep the radiation pattern stable.

Performance Validation:

| Surface Type | Read Range (Flat) | Read Range (Curved) |

|---|---|---|

| Stainless Steel Pipe | 12m | 11.2m (-6.7%) |

| PVC Conduit | 12m | 11.8m (-1.7%) |

Pro Tip: Use a vector network analyzer to verify VSWR remains ≤1.8:1 post-installation.

The CK-FL1 can handle tough conditions thanks to its IP68 polyimide design, but very high humidity, chemical exposure, and extreme temperature swings need extra steps. In humid spaces over 90% RH, add a thin silicone coating to keep moisture out. For oil or gas sites, an FKM overlay protects against hydrocarbons and H₂S. With big temperature swings, give the antenna time to stabilize and use thermal gap pads on hot surfaces to prevent delamination. In one automotive plant, these measures helped maintain 99.3% read accuracy on engine blocks.

Mount the antenna on a conveyor running 2.5 m/s and test with dense tags at 30 dBm, aiming for at least 97% reads over eight hours. For rotating parts, attach to a drum and watch impedance drift and adhesive strength. If signals drop, look for micro-cracks; if read rates fluctuate, recalibrate with the tuning tool; if edges start peeling, let epoxy cure longer in cold conditions.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.