Submit your request to us

We will contact you as soon as possible.

All RFID Product

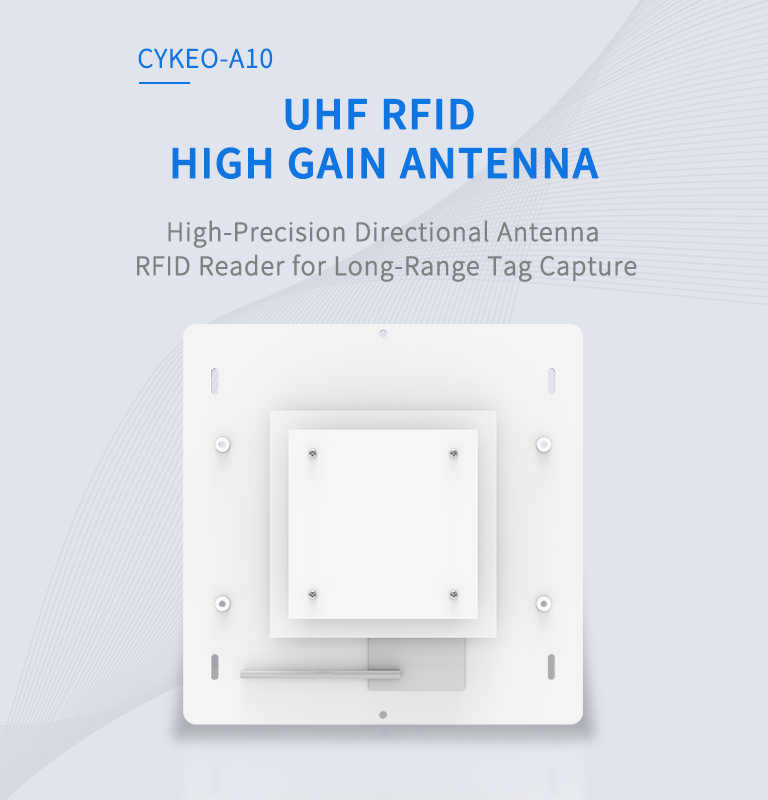

CYKEO-A10

High-Precision Directional Antenna RFID Reader for Long-Range Tag Capture

✔️ IP67-rated aluminum housing with surge and dust protection

✔️ 902–928 MHz adaptive tuning for stable UHF global use

✔️ 10.5 dBi directional Antenna RFID Reader supporting 20 m+ real-world coverage

TThe CYKEO CYKEO-A10 Antenna RFID Reader is made for teams that need a long-reach UHF setup without adding complexity. The directional beam and circular polarization work together to keep tag detection steady from different angles, making it suitable for warehouse corridors, automated lines, or outdoor gates. Its rugged build handles constant vibration, temperature swings, and the usual bumps seen in loading areas.

You can deploy it on dock doors, conveyor checkpoints, or vehicle access points where a reliable rfid reader antenna has to deliver consistent long-range reads without constant retuning.

Main Specifications

Physical Parameters

Developer Support

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

In fast-moving warehouse lanes, small adjustments often make a big difference. Mount the antenna at a moderate height—around three meters—and tilt the beam slightly downward to widen the reading path. Circular polarization helps pick up tags even when cartons tilt or rotate on conveyors. Keep output around 30–33 dBm and allow frequency hopping so the reader avoids Wi-Fi overlap. When several antennas work close together, enabling dense-reader mode keeps interference in check.

With proper alignment, accuracy climbs noticeably. On metal racks, operators often see tagging consistency above 98% compared to the lower rates typical of general-purpose antennas.

The CYKEO CYKEO-A10 uses an aluminum radome with an IP67 seal to block moisture, dust, and harsh air. The housing remains stable under UV exposure and wide temperature ranges. Internal shielding keeps noise away from the sensitive RF chain, and built-in surge protection helps during storms or power fluctuations. Vibration tolerance allows the antenna to be fixed on machinery or frames without drifting. If installing on metal walls or pillars, using spacers prevents the beam from collapsing.

CYKEO keeps integration straightforward. The CYKEO-A10 supports LLRP, ALE 1.1, and common REST formats, letting older WMS platforms receive EPC data without heavy updates. Local processing reduces network stress, and the device stores readings during short outages. Developers can rely on available SDKs for Java or Python to add zone logic or create movement alerts. Companies shifting from barcode-only systems often use this rfid reader antenna in mixed setups until their full automation project is ready.

Industries—from logistics to healthcare and energy—use the CYKEO-A10 to stabilize tracking at gates, sorter exits, and equipment checkpoints, especially where UHF long range RFID antennas help streamline daily operations.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.