What Type of Antenna Do Passive RFID Tags Use? A Look Inside the Sticker.

209Learn what type of antenna passive RFID tags use. We clarify the difference between coil antennas for proximity and printed dipoles for UHF logistics tracking.

MoreAll RFID Product

Unlike traditional RFID that relies on standard chip packaging, Chipless RFID encodes data through material structures or printed patterns, allowing more flexible designs and structures.

Chipless RFID tags support customization in shape, material, and color, and meet OEM/ODM demands across applications such as anti-counterfeiting packaging, ticketing, and logistics labeling.

With a highly flexible structure, these tags adapt well to personalized customization in appearance and material for diverse use scenarios.

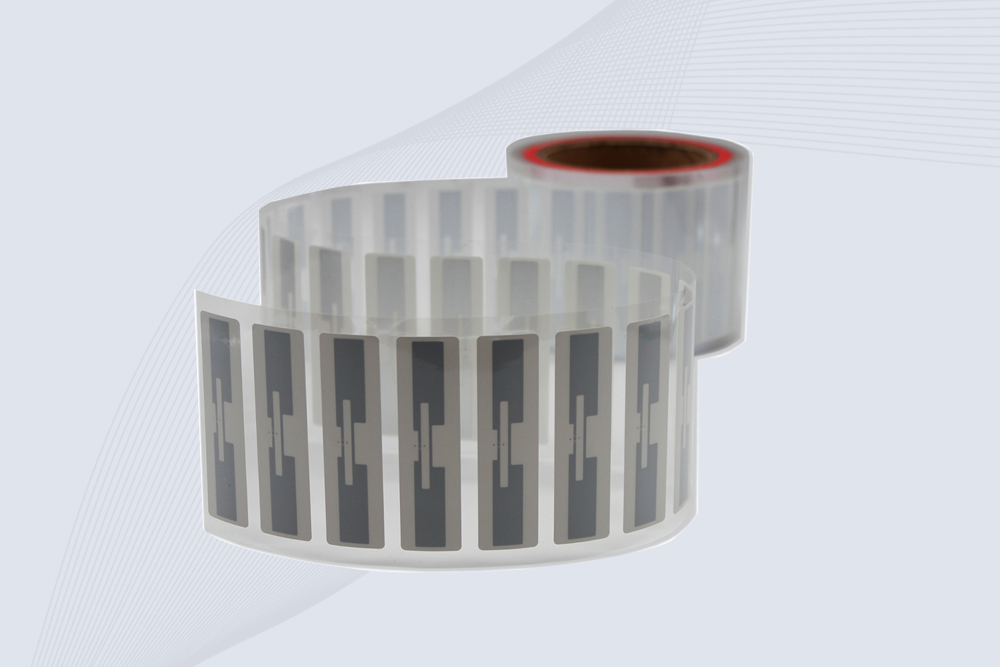

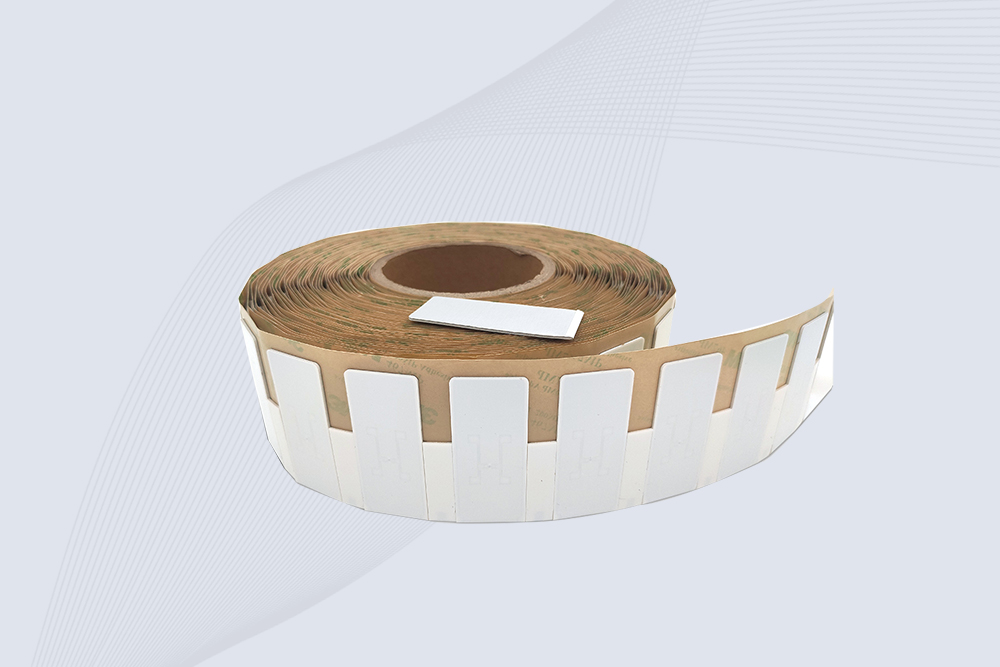

Chipless RFID tags can be tailored to suit the product shape and attachment environment. Common structures include:

Most tags are between 0.1–0.8mm thick, supporting automated labeling and flexible embedding.

Chipless RFID tags can be customized in both size and shape to suit packaging and embedding needs.

One of the key strengths of Chipless RFID is the ability to use non-conductive, flexible materials that encode data through printing or etching. Common base materials include:

Chipless RFID supports customization using paper, plastic, fabric, and other materials to meet both durability and environmental goals.

To meet branding and traceability requirements, Chipless RFID tags support a variety of OEM processing techniques:

| Process | Application | Description |

|---|---|---|

| Screen printing | LOGOs, barcodes, encoded batches | Ideal for plastic or paper-based tags |

| Inkjet printing | Dynamic serial numbers, batch info | Enables unique identification for each tag |

| Hot embossing | Brand protection, tamper seals | Creates embossed surfaces for anti-counterfeiting |

| Full-color printing | Product tags, event tickets, ads | Supports CMYK and four-color printing |

| QR/Barcode embed | Dual scan + RFID interaction | Enhances compatibility with visual ID and RFID |

Some manufacturers also offer laser engraving, UV ink printing, and waterproof lamination.

Chipless RFID tags support screen printing, inkjet coding, embossing, and color printing to meet branding and traceability needs.

Businesses typically follow these steps to customize Chipless RFID tags:

The typical turnaround from requirement confirmation to batch delivery is 7–15 working days, depending on processing and quantity.

Chipless RFID tag customization follows a streamlined process with flexible production cycles, ideal for brand personalization and fast deployment.

Chipless RFID tags offer high customization flexibility, adapting to a wide range of shapes and environments. They also support rich OEM printing and processing options, providing cost-effective intelligent identification for anti-counterfeiting, traceability, and logistics.

By partnering with professional suppliers, businesses can quickly deploy branded, functional, and scenario-specific Chipless RFID tag systems tailored to their unique product needs.

CYKEO Passive RFID Tags are made for wet and high-humidity environments where standard labels do not last. This rfid passive tag is often used around liquids, chemicals and temperature changes, providing stable reading distance and long data life for industrial tracking.

CYKEO CK-BQ1504 Metal RFID Tags is a compact anti-metal UHF RFID solution built for direct mounting on metal surfaces. With stable 8-meter read range, Ucode-8 chip, and long data retention, this rfid metal tag fits tools, containers, automotive parts, and industrial asset tracking.

CYKEO CK-BQ7020 On-Metal RFID Tags are designed for reliable tracking on steel and metal surfaces. Built with an FR4 epoxy body and industrial-grade chips, these On-Metal RFID Tags deliver stable performance, long data life, and chemical resistance, making them a dependable RFID anti-metal tag for harsh environments.

The CYKEO CK-BQ6025 Anti-Metal RFID Tag is built for metal surfaces where standard tags fail. Designed for long-range performance, harsh environments, and stable data retention, this Anti-Metal RFID Tag is ideal for industrial assets, containers, and equipment tracking using on metal RFID tags.

Learn what type of antenna passive RFID tags use. We clarify the difference between coil antennas for proximity and printed dipoles for UHF logistics tracking.

MoreWondering how to connect RFID reader to database? We break down the real-world steps, from data capture to SQL integration, and show how CYKEO makes it simpler.

MoreExplore how an rfid scanner iphone works in real projects. Learn NFC limits, external reader options, and practical setup tips using CYKEO mobile RFID solutions.

MoreProtect your fixed RFID readers from cyber threats with Cykeo’s expert strategies. Learn encryption, network hardening, and compliance practices to safeguard sensitive data.

More