What are the advantages and disadvantages of QR codes and NFC tags/RFIDs?

657Compare QR codes and NFC/RFID tags for your business. Discover their pros and cons in cost, security, and usability to choose the right identification technology.

MoreAll RFID Product

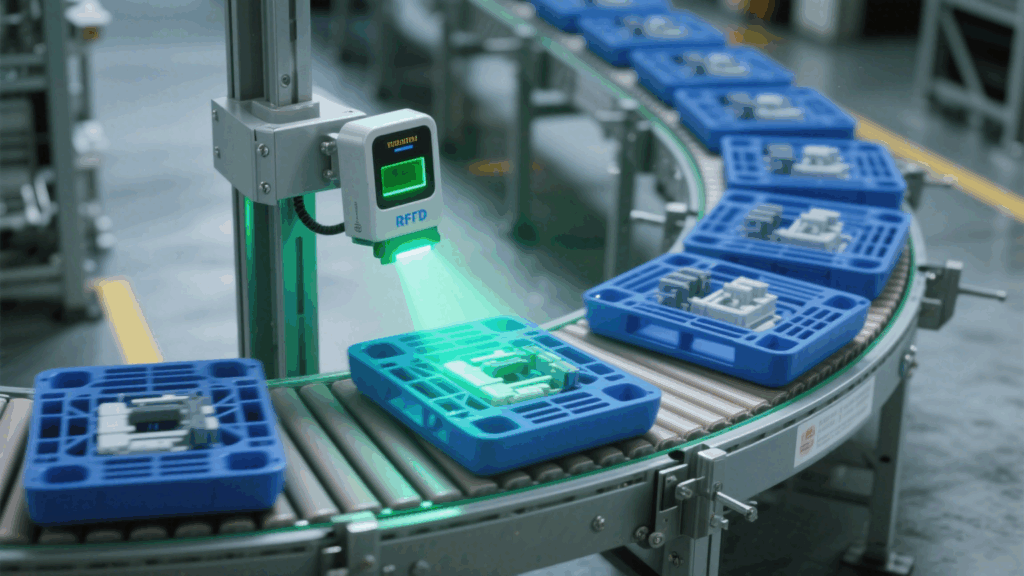

Industrial RFID Reader is radio frequency identification device designed specifically for harsh industrial conditions. It operates reliably in high temperatures, humid or dusty areas, and environments with strong electromagnetic interference. Unlike commercial-grade RFID readers, industrial RFID readers support stable and efficient data reading and writing over long periods. These devices are widely used in automated production lines, smart warehouses, and asset management systems.

High-performance Industrial RFID Reader offers the following capabilities:

Industrial RFID Readers are widely used in the following scenarios:

To choose the right Industrial RFID Reader, consider these factors:

With the rise of Industry 4.0 and IoT, Industrial RFID Readers continue to evolve in the following directions:

Industrial RFID Readers play vital role in industrial IoT by transforming traditional factory operations. Deploying high-performance RFID readers helps manufacturers achieve real-time visibility and intelligent management across production, warehousing, and logistics. This boosts both operational efficiency and accuracy, making RFID foundational technology for the future of smart manufacturing.

Cykeo CK-BQ6826 Jewelry uhf rfid tag features NXP UCODE 9, 8m read range on metal, and anti-counterfeit security for luxury assets.

Cykeo CK-BQ8554HF HF rfid cards feature FM1108 chip, 100K write cycles, and customizable printing for access control systems.

Cykeo CK-BQ8554UHF uhf rfid card features U9 chip, 100K write cycles, and CR80 size for access control/inventory management.

Cykeo CA-BFT hf rfid archive cabinet features 99.97% read accuracy, 75 compartments, and chain-of-custody tracking for high-security archives.

Compare QR codes and NFC/RFID tags for your business. Discover their pros and cons in cost, security, and usability to choose the right identification technology.

MoreLearn how to deploy multi-reader RFID systems for seamless warehouse coverage. Optimize placement, avoid interference, and integrate Cykeo’s solutions for maximum efficiency.

MoreWondering whether RFID or barcodes are more cost-effective? This article compares the cost of RFID tags vs barcodes and helps you decide based on your business needs and budget.

MoreRFID toll gate systems have become vital tools for digitalized traffic management.

More