How can I improve RFID tag read range with handheld readers?

553Boost RFID tag read range with handheld readers using antenna adjustments, tag placement, and power settings. Learn actionable strategies for warehouses and outdoor use.

MoreAll RFID Product

In today increasingly digitalized warehousing and supply chain environment, RFID technology has become a go-to tool for many wholesalers and logistics companies due to its fast identification, bulk reading, and precise tracking capabilities. Compared to traditional barcode systems, RFID excels in automation and real-time operations.

By attaching UHF RFID tags to pallets, cartons, or even individual products, warehouses can monitor inventory in real time. When goods pass through RFID gates, conveyors, or tunnels, the system automatically identifies them—no manual scanning required.

Value in Practice:

Automated inventory counting without halting operations

Real-time visibility of item quantity and location

Reduced loss and misdelivery rates

Traditional receiving/shipping requires manual document checks and barcode scanning. RFID enables batch identification of goods as they pass, greatly improving workflow efficiency.

Use Case Examples:

Fixed RFID gates in the receiving area

System automatically verifies outbound orders

Alerts triggered for quantity mismatches

Using RFID markers or zone identifiers, the system can automatically log the storage location of goods. Workers with handheld RFID readers can quickly locate materials when needed.

Scenario Value:

Eliminate time wasted searching for inventory

High accuracy, reduced misplacement

Ideal for cold chain and hazardous material zones

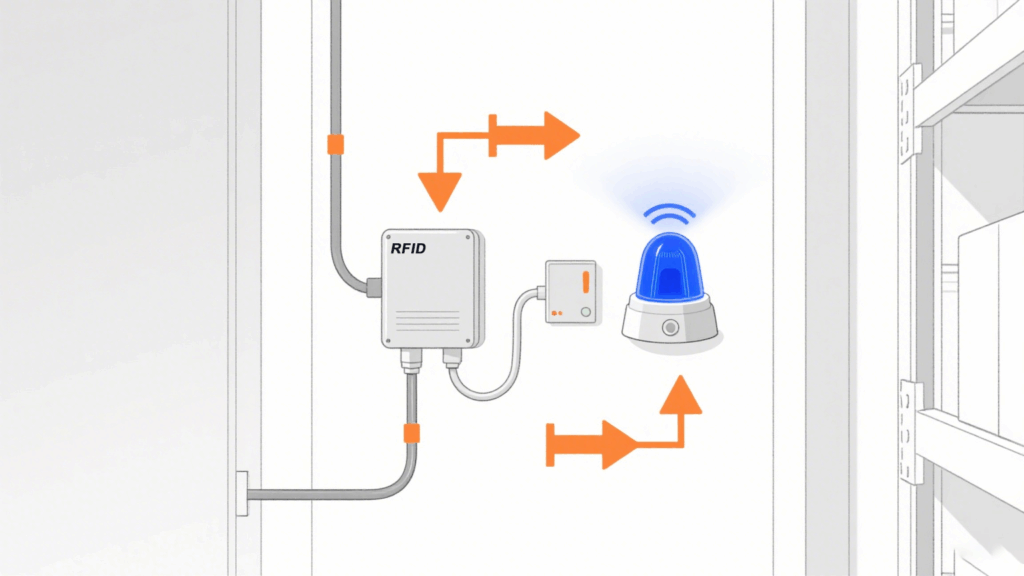

RFID can integrate with security systems to detect unauthorized movement of goods. Alarms can be triggered when high-value or restricted items are moved without authorization—ideal for consumables, electronics, and component storage.

Typical Features:

Real-time alerts for abnormal movement

Access and exit logs for every item

Permission-based zone control

By setting periodic inventory checks, the system can trigger RFID reading devices to conduct full inventory audits and export analysis reports—empowering management with data-driven insights.

Advantages:

Quickly count thousands of items

Automatically generate Excel/ERP-compatible reports

Custom analytics (e.g., turnover rate, unsold stock)

With the advancement of logistics automation and digitization, RFID is no longer exclusive to large enterprises. More and more SMEs are adopting warehouse RFID systems. Choosing solution tailored to your warehouse size and business needs can bring significant improvements in efficiency and cost reduction.

Cykeo CYKEO-C2 UHF RFID inventory cart features 10 UHF readers, 500 tags/sec scanning, Windows/Android OS, and hybrid power for warehouses/libraries. Supports ISO 18000-6C protocols and customization.

Cykeo’s industrial RFID Inventory Tracking station features dual scanning modes, 200+ items/sec bulk reading, and SAP integration for precise warehouse management. MIL-STD-810G certified with Windows/Android OS.

Cykeo CYKEO-D7 RFID system for inventory offers 40+ tags/sec scanning, 150L secure storage, and Impinj R2000 chipset for warehouses, toolrooms, and retail. Global frequency compliance (840-960MHz).

Cykeo CYKEO-C1 mobile RFID scanner cart features PLC-controlled antenna lifting, 10-tag/sec reading, and 21.5″ touchscreen for libraries, hospitals, and warehouses. Supports Windows/Android and multi-protocol RFID.

Boost RFID tag read range with handheld readers using antenna adjustments, tag placement, and power settings. Learn actionable strategies for warehouses and outdoor use.

MoreDiscover how passive UHF RFID tags work, what types exist, and how to select the right tag for your application. A practical guide for warehouse tracking, retail, and industrial automation.

MoreFacing rfid reader not working issues? Discover practical troubleshooting tips, common failure causes, and proven CYKEO solutions to restore stable RFID performance fast.

MoreDiscover how RFID technology, featuring the CK‑TP4A retractable UHF RFID gate, streamlines warehouse and inventory management. Improve efficiency, accuracy, and real-time tracking for large-scale warehouses and high-volume inventory operations.

More