Your RFID Reader Works, Until It Needs to Read Just One Item

Here’s a scene we see too often. A quality control technician in a medical device plant tries to scan a single tagged component from a tray of 50 identical parts. The handheld reader beeps, but the software shows the wrong serial number—it read a part from the neighboring tray instead. This isn’t a software bug. It’s a hardware mismatch. The standard antenna on that reader is designed to cast a wide net, not to perform precise, close-up work. This daily frustration is the exact problem a robust UHF near-field RFID reader antenna is built to eliminate.

Why “Robust” Here Means “Predictable Under Pressure”

In our lab, when we test a near-field antenna, “robustness” isn’t about surviving a drop test (though that matters). It’s about consistency. Can this antenna produce the exact same magnetic field, with the exact same boundaries, for the 10,000th scan as it did for the first? In environments like clean rooms, assembly lines, or tool cribs, that repeatability is everything.

A truly robust UHF near-field RFID reader antenna achieves this through a combination of physical and electrical design. The housing is just the start—it needs to be sealed against dust, moisture, and chemical splashes (think isopropyl alcohol wipes in a lab). More importantly, the antenna element inside, usually a carefully etched pattern on a PCB, must be isolated from the housing and any mounting surface. If the antenna’s electrical properties shift when you bolt it to a metal workbench or when the room temperature changes, it’s not robust. It’s unreliable.

The Real Cost of Getting This Wrong

The solving near-field RFID read failures isn’t an academic exercise. We worked with a pharmaceutical packager who was using a standard handheld to verify vial labels before boxing. Their error rate was 2%. That sounds low until you realize it meant 20 misplaced vials per 1,000—a catastrophic risk. The issue was stray reads. Their antenna’s field was too diffuse, picking up tags from vials in the next row on the conveyor.

We replaced it with a purpose-built, robust near-field antenna mounted in a fixed position above the conveyor. Its field was engineered to be sharp and shallow, like a precise laser line. It only energized tags on the vial directly beneath it. The error rate dropped to zero. This is the tangible impact: moving from “mostly works” to “must work every time.”

How to Spot a Truly Durable Antenna for Your Application

Selecting durable near-field reader antennas requires asking different questions than you would for a general-purpose antenna. Here’s our field checklist:

- Ask About the “Field Map”: Don’t just ask for the read range. Ask the supplier for a measured field contour map. How sharply does the signal strength fall off at the edges? A steep drop-off is good—it means precise control.

- Demand Environmental Specs: What’s the operating temperature range? What’s the IP rating? If it’s IP65, will it survive a high-pressure washdown in a food plant? The specs should match your reality.

- Test with Interference: Test the antenna in its final location with all equipment running. Does a nearby motor or wireless router cause read failures? A robust design includes filtering to ignore this noise.

For industrial near-field RFID applications—verifying surgical tool sets, authenticating circuit boards, or logging library archives—the antenna is the most critical component. A reader is just a computer. The antenna is its sense of touch.

When you specify a robust UHF near-field RFID reader antenna, you’re not buying a commodity. You’re investing in a precision instrument that turns a chaotic, error-prone manual check into a reliable, automated verification step. It’s the difference between hoping your system works and knowing it will.

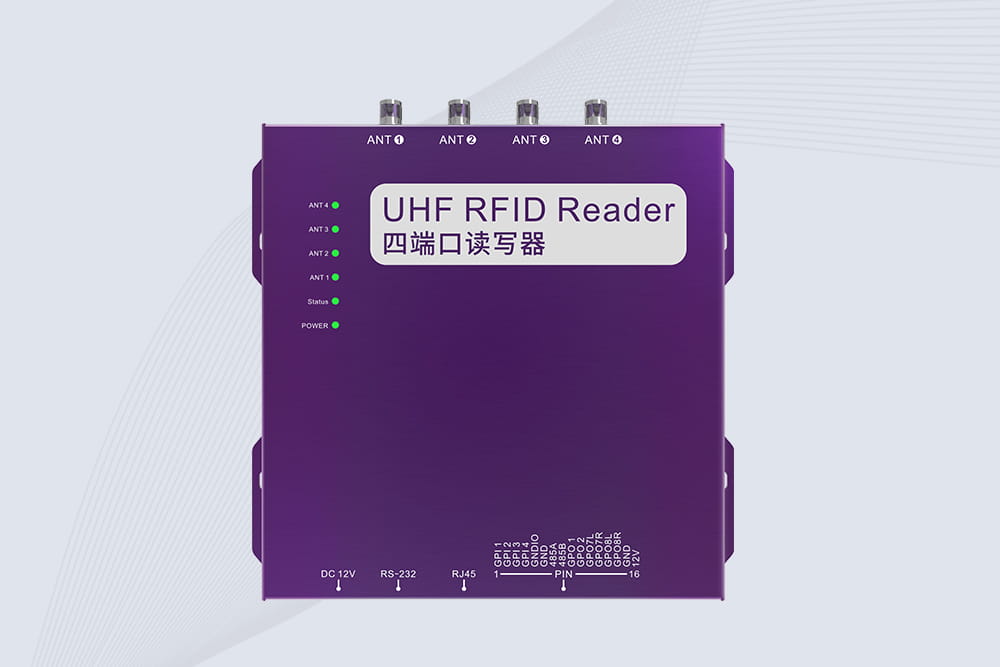

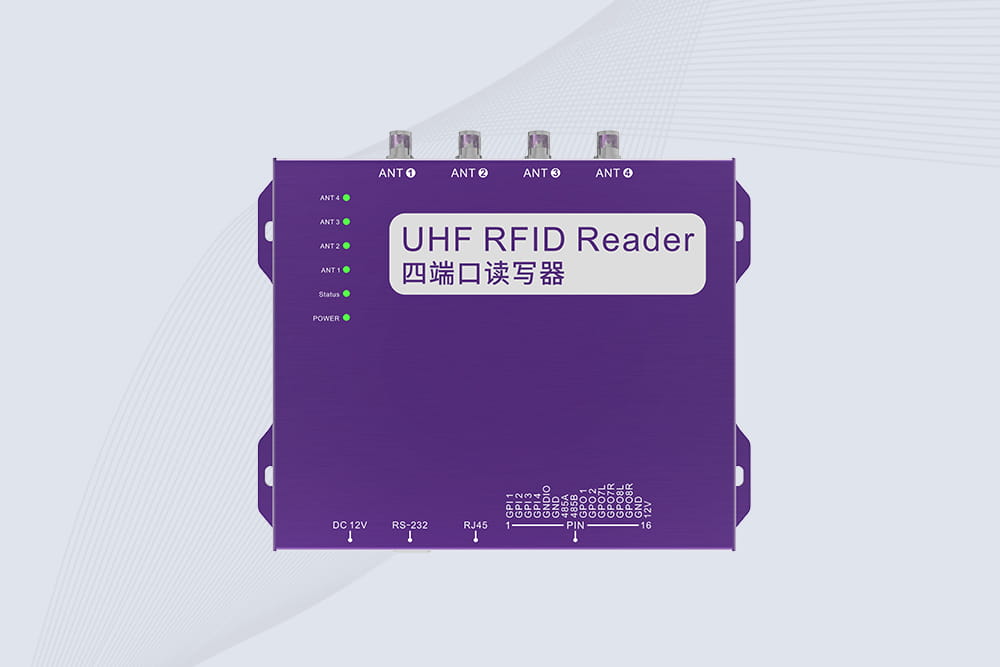

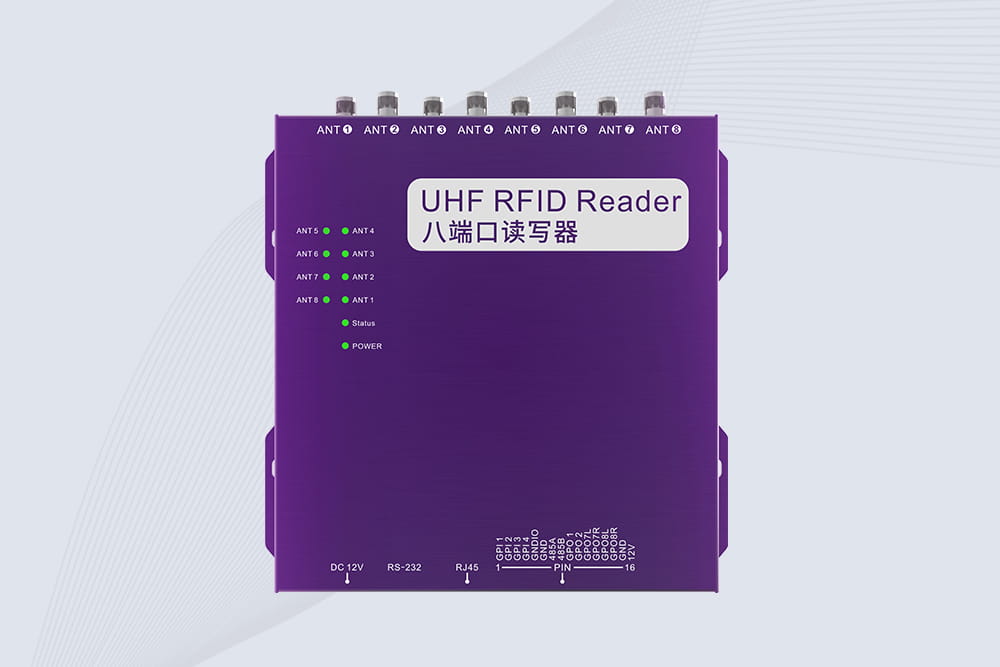

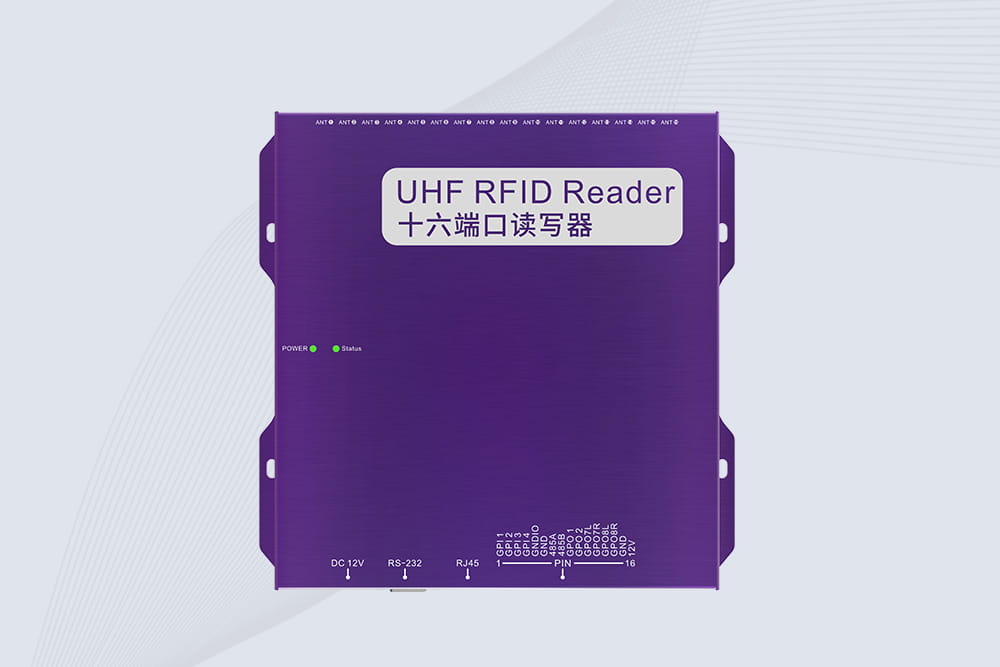

RFID Reader Recommendation

Cykeo RFID IoT Solution Products R&D Manufacturer

Cykeo RFID IoT Solution Products R&D Manufacturer