What is an RFID Antenna? (Hint: It’s the Most Important Piece You’ll Buy)

63Tired of confusing tech jargon? We give you a straight answer on what is an RFID antenna, why it matters, and how to avoid common setup mistakes that waste money.

MoreAll RFID Product

If you’ve ever spent time in a real warehouse, a dock door lane, or one of those busy internal logistics corridors… you already know the truth: relying on people to manually scan everything just doesn’t work. Trucks roll in nonstop, pallets pile up, staff move around like it’s rush hour. There’s no way every item, every container, every asset gets recorded properly.

Missed scans. Wrong scans. Forgot-to-scan moments. It happens constantly.

That’s exactly why RFID gates matter.

And honestly, Cykeo’s CK-T8D RFID Gate Access Control System feels like one of those “not pretty for show, but damn reliable” pieces of equipment. Industrial. Practical. No drama.

Let me break it down in a way people on the ground would actually understand.

Because it solves the actual pain points—not the imaginary ones.

This is huge.

Stopping a cart, a pallet, or a trolley for scanning is… let’s be honest… a productivity killer.

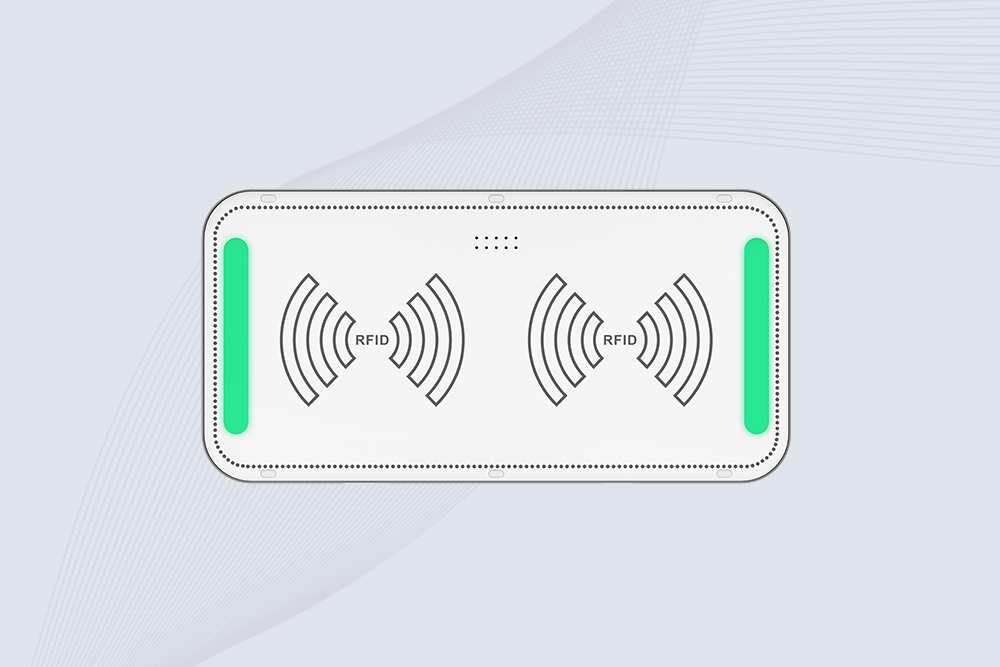

The CK-T8D’s antenna coverage and read stability mean you can push an entire load through the gate in one go.

No pausing.

No repeating.

Just pass through. And it’s done.

Feels good.

Sounds simple. Many gates fail here.

Some systems read tags, but can’t tell whether they were entering or leaving.

That’s dangerous for inventory accuracy.

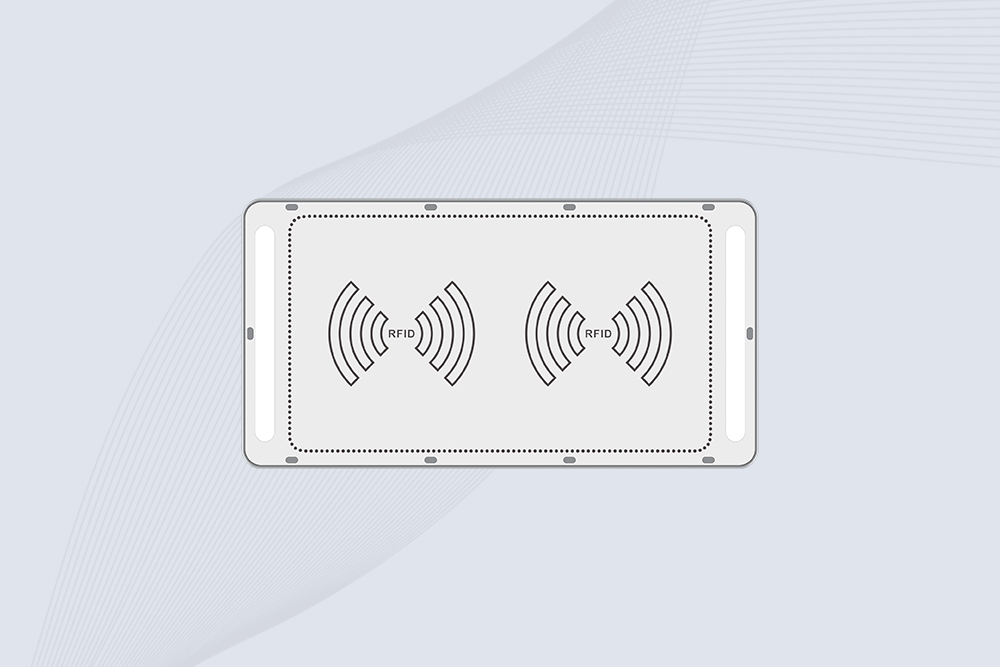

The CK-T8D uses structured gate logic—physical channel + directional logic—so it knows exactly how tags move.

In from this side? Logged.

Out from the other side? Also logged.

Way more reliable than those “try to guess direction using antenna field strength” methods.

Warehouses are noisy.

Metal racks, forklifts, machines, constant signal reflections… a nightmare for many UHF systems.

But the CK-T8D handles it surprisingly well.

Low miss rate.

Stable reads.

It behaves like a device tuned for actual industrial chaos—not clean lab conditions.

I respect that.

Another underrated point.

Some gates demand trenching, special concrete fixtures, or rewiring half the building.

You know… the type of project that turns into a mini construction site.

The CK-T8D?

Plug where you can plug. PoE if you want it.

Standalone power if needed.

No forced big renovation.

Your engineers will thank you.

This one matters for IT teams.

The CK-T8D speaks the common languages—so tying it into WMS, access control systems, or an inventory platform doesn’t require translation layers or weird middleware.

It integrates like a normal, modern industrial device should.

Push a trolley full of tagged totes through the gate.

Boom. Everything logged automatically.

No handheld scanners. No extra steps.

Trucks move quickly.

Stopping them just to scan is unrealistic.

The gate logs containers and assets in motion.

Simple. Clean.

Material moves from Station A to Station B?

Passing through the gate is the record.

Zero manual involvement.

Some facilities need strict control.

A gate provides a clear digital footprint of every movement.

Reliable. Traceable.

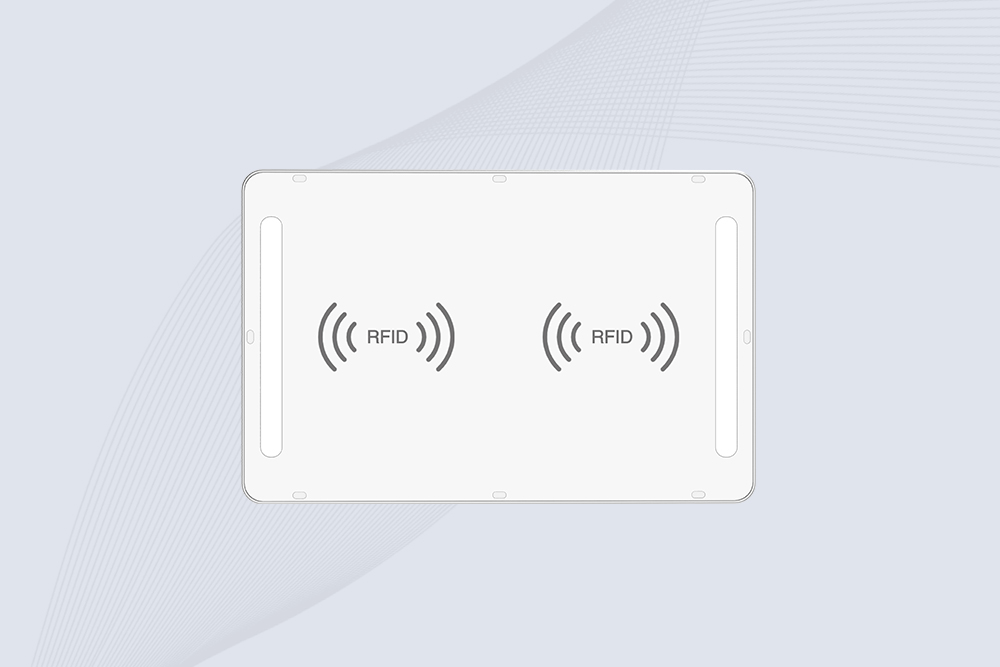

Because let’s be honest—

A lot of so-called “RFID gates” on the market are just:

a frame + some antennas + a reader box.

They look like a gate, but they’re basically DIY assemblies.

The CK-T8D feels more like a system, not a collection of parts.

Clear structural logic.

Smart read algorithms.

Directional judgment.

Scenario-specific tuning.

It behaves like something designed by people who have actually walked real warehouse floors—not engineers stuck in an office.

That’s the difference.

If your problems today are:

Then an industrial-grade RFID gate like the CK-T8D will honestly make your entire operation feel… lighter.

Cykeo’s CYKEO-T1D industrial RFID ceiling reader features 500 tags/sec scanning, IP54 protection, and -20℃~60℃ operation for retail/warehouse security. Supports ISO18000-6C and GB/T29768 protocols.

Cykeo’s ceiling-mounted RFID reader enables hands-free 5m inventory tracking with 500 tags/min speed. Features dual alerts, ERP integration, and IP54 rating for warehouse security.

Cykeo CK-T1E RFID gate system features 120° coverage, AI motion filtering, and 5m detection for retail/warehouse security. IP67 rugged design with ERP integration.

Cykeo CYKEO-T1A industrial ceiling RFID system offers 10-20m read range, 500+ tags/sec speed, and IP65 protection for smart warehousing. Supports multi-protocol integration and real-time inventory alerts.

Tired of confusing tech jargon? We give you a straight answer on what is an RFID antenna, why it matters, and how to avoid common setup mistakes that waste money.

MoreUsing RFID tags for books allows fast borrowing, returning, inventory, and theft prevention, making library management efficient and convenient.

MoreDiscover how RFID technology transforms healthcare facility management. Learn how UHF RFID systems, mobile readers, and smart tagging improve asset tracking, patient safety, and workflow efficiency.

MoreEver wondered how does an RFID reader work? We break down the process into simple steps, from powering tags to reading data, without the confusing jargon.

More