RFID vs NFC Tags: How to Pick the Right Tech

916RFID vs NFC tags: Understand key differences in range, cost & real-world use cases. Learn when NFC's phone compatibility beats RFID's bulk scanning.

MoreAll RFID Product

Let’s be honest—RFID tags always look amazing in a PowerPoint deck: “10-meter read range, interference-proof, 10-year lifespan.” But once you get to the actual site, reality hits: a single forklift scrape can kill a tag, and one burst of Wi-Fi noise can cut your read range in half.

I still remember my first field test in a cold chain warehouse in Fuyong, Shenzhen. The supplier’s samples performed flawlessly in the lab, but once we stuck them on a row of metal racks, the read success rate crashed from 98% to under 60%.

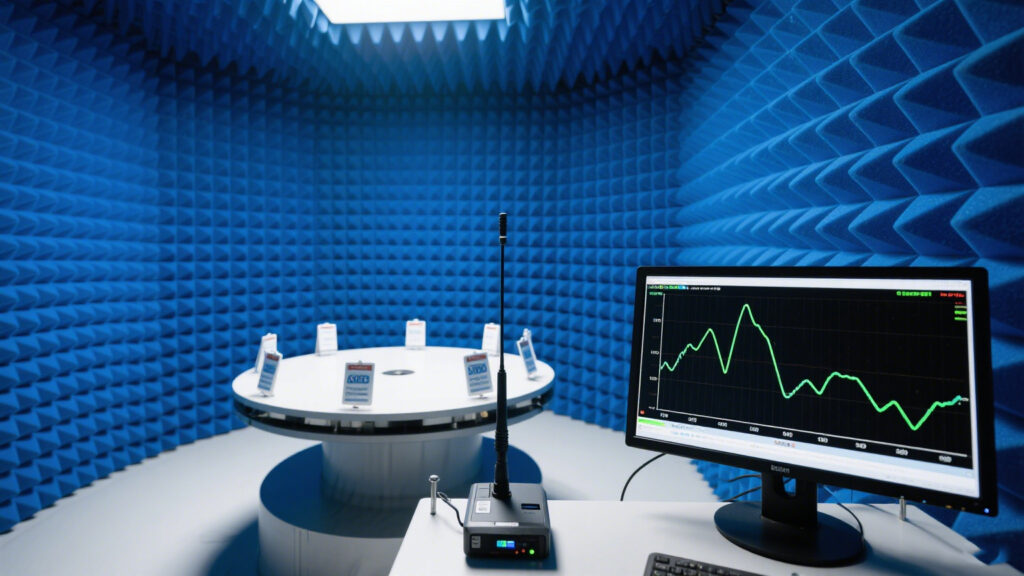

When a tag comes straight off the production line, we usually start with basic tests inside an anechoic chamber.

Lab success doesn’t guarantee smooth sailing in the field.

If you leave an access card in the reader’s field, the reader often doesn’t really “know” it’s still there.

While retrofitting a hotel’s room card energy-saving system, I used Arduino + MFRC522 to read the card UID every 500ms. If it failed to read for 3 seconds, it would turn off the AC. A crude method, but better than waiting for guest complaints.

Pro tip: Don’t let the reader keep transmitting continuously—module heating can hurt stability.

If you just want to know whether a tag is a 13.56 MHz NFC type, the simplest trick is to use an Android phone with NFC Tools—tap and get the data.

For HID, AWID, and other access cards, you’ll need “black box” gear like the Proxmark3. Once, during a port security upgrade in Shekou, we used it to pull protocol info from a batch of US-standard cards—the manufacturer couldn’t even tell us the exact model.

The lab is a paradise for tags, but the warehouse is their hell. Only in the real world will you know whether a “perfect” tag can actually survive project acceptance.

RFID tag testing is never just “plug it in and press start.” From standardized anechoic chamber trials to interference-heavy warehouse battles, every step hides pitfalls. Don’t blindly trust vendor specs—or even your own first results. Test in multiple environments, angles, and interference conditions—that’s the only way to truly validate a tag’s reliability.

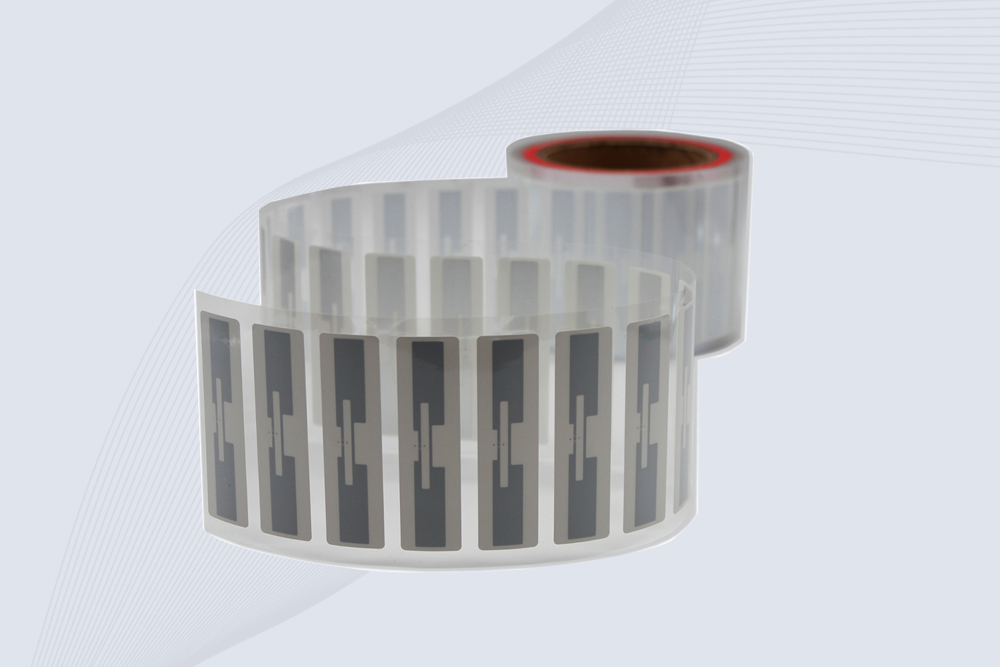

CYKEO Passive RFID Tags are made for wet and high-humidity environments where standard labels do not last. This rfid passive tag is often used around liquids, chemicals and temperature changes, providing stable reading distance and long data life for industrial tracking.

CYKEO CK-BQ1504 Metal RFID Tags is a compact anti-metal UHF RFID solution built for direct mounting on metal surfaces. With stable 8-meter read range, Ucode-8 chip, and long data retention, this rfid metal tag fits tools, containers, automotive parts, and industrial asset tracking.

CYKEO CK-BQ7020 On-Metal RFID Tags are designed for reliable tracking on steel and metal surfaces. Built with an FR4 epoxy body and industrial-grade chips, these On-Metal RFID Tags deliver stable performance, long data life, and chemical resistance, making them a dependable RFID anti-metal tag for harsh environments.

The CYKEO CK-BQ6025 Anti-Metal RFID Tag is built for metal surfaces where standard tags fail. Designed for long-range performance, harsh environments, and stable data retention, this Anti-Metal RFID Tag is ideal for industrial assets, containers, and equipment tracking using on metal RFID tags.

RFID vs NFC tags: Understand key differences in range, cost & real-world use cases. Learn when NFC's phone compatibility beats RFID's bulk scanning.

MoreStruggling with rfid reader distance measurement in real projects? Learn field-tested range methods, common mistakes, and CYKEO setup tips that improve reading accuracy.

MoreCykeo compares RFID and barcode scanners for logistics cost savings. Discover why 63% of warehouses now prefer UHF RFID for 90% faster scans and 40% lower labor costs.

MoreRFID metal interference causes missed reads and system failures. Learn proven ways CYKEO reduces interference in real industrial environments.

More