How to Secure Data Transmission in Long-Range RFID Networks?

976Learn how to protect data in long-range RFID networks from interception or tampering. Discover Cykeo’s encryption, authentication, and compliance strategies for secure operations.

MoreAll RFID Product

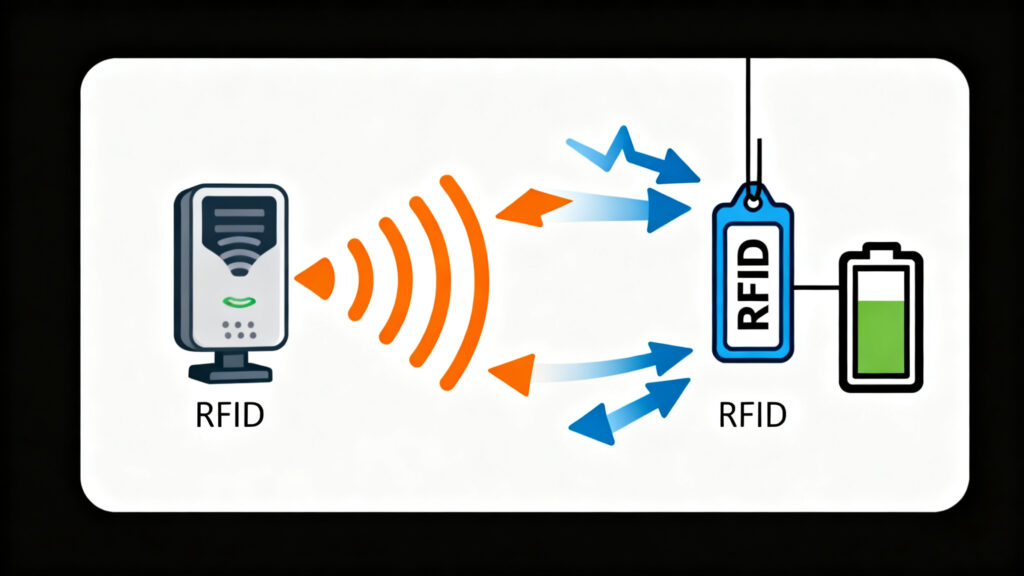

When people talk about RFID passive and active tags, they are usually trying to figure out which technology fits their project best. RFID has been around for decades, but only in the last few years has it moved from niche logistics systems into everyday applications—think retail security, asset tracking, or even smart parking systems. To understand the difference between passive and active tags, it helps to break things down into how they work, what they cost, and where they are commonly used.

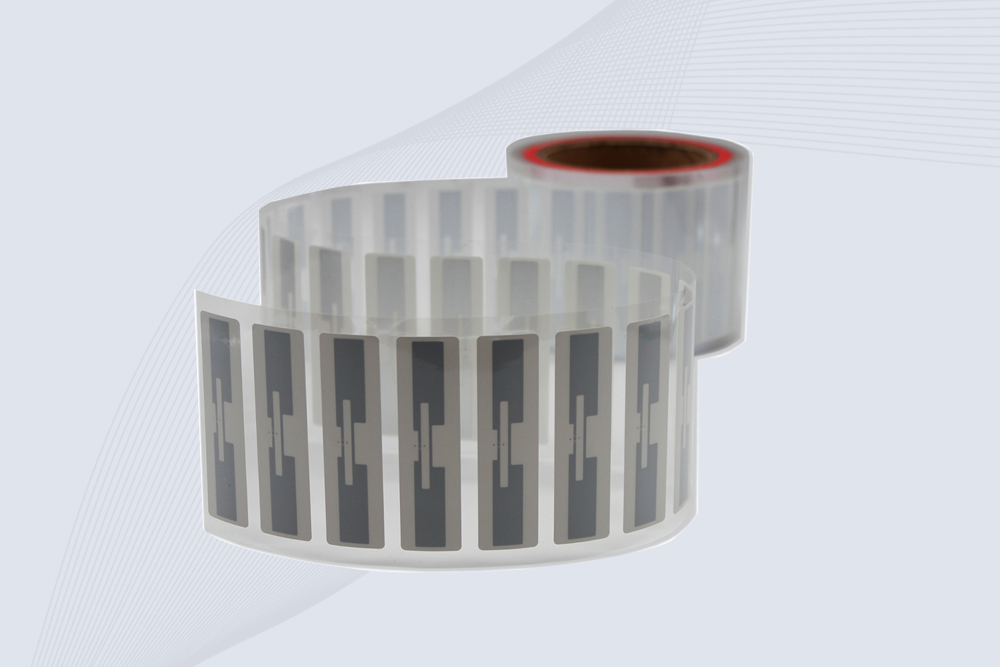

A passive RFID tag has no battery inside. It’s like a mirror that wakes up only when light hits it. Instead of light, it uses energy from the RFID reader’s radio waves. Once the tag receives that energy, it reflects back a signal with its unique ID or stored data.

Because of this design:

Think of passive tags as stickers or labels that quietly sit there until someone scans them.

In contrast, an active RFID tag has its own battery and sometimes even sensors built inside. Instead of waiting for the reader’s energy, it actively sends signals. This is more like a small walkie-talkie that constantly shouts its ID to anyone listening.

Key characteristics:

Active tags are often used in high-value tracking scenarios: tracking medical equipment in hospitals, containers in shipping yards, or even employees inside secure facilities.

| Feature | Passive RFID Tags | Active RFID Tags |

|---|---|---|

| Power Source | No battery (powered by reader) | Built-in battery |

| Read Range | Short to medium (cm to ~10 m) | Long (10 m to 100+ m) |

| Size | Small, lightweight | Larger, bulkier |

| Cost per Tag | Very low (cents) | High (dollars+) |

| Lifespan | Practically unlimited | Limited by battery life |

| Applications | Retail, libraries, access control | Asset tracking, logistics, real-time monitoring |

This table gives the quick snapshot, but the decision usually comes down to balancing cost vs. performance.

The key point: if you just need to identify lots of items cheaply, passive tags are the answer. If you need real-time location data across a wide area, active tags are worth the investment.

A lot of people assume that passive RFID is “worse” than active RFID because the range is shorter. That’s not true—it just solves a different problem. In fact, many retailers wouldn’t even consider active RFID because the cost would be too high. On the flip side, using passive tags in a massive shipping yard would be frustrating because readers can’t pick up signals from hundreds of meters away.

Understanding rfid passive and active tags is really about knowing what you need from your RFID system. Passive tags are cheap, durable, and perfect for high-volume, low-cost tracking. Active tags, though more expensive, open the door to long-range, real-time monitoring that passive tags simply can’t provide.

Before making a choice, always match the tag type with the application. It’s like choosing between a bicycle and a car—both get you from A to B, but the context matters.

Q: Can passive and active RFID tags work together?

Yes. Some systems combine both, using passive tags for item-level tracking and active tags for high-value assets.

Q: Do active RFID tags always need replacement?

Eventually yes, because the battery runs out. Lifespan varies from 3 to 10 years depending on usage.

Q: Which is more secure, passive or active?

Security depends more on the system design and encryption, not the tag type. Both can be secured if the right protocols are used.

CYKEO Passive RFID Tags are made for wet and high-humidity environments where standard labels do not last. This rfid passive tag is often used around liquids, chemicals and temperature changes, providing stable reading distance and long data life for industrial tracking.

CYKEO CK-BQ1504 Metal RFID Tags is a compact anti-metal UHF RFID solution built for direct mounting on metal surfaces. With stable 8-meter read range, Ucode-8 chip, and long data retention, this rfid metal tag fits tools, containers, automotive parts, and industrial asset tracking.

CYKEO CK-BQ7020 On-Metal RFID Tags are designed for reliable tracking on steel and metal surfaces. Built with an FR4 epoxy body and industrial-grade chips, these On-Metal RFID Tags deliver stable performance, long data life, and chemical resistance, making them a dependable RFID anti-metal tag for harsh environments.

The CYKEO CK-BQ6025 Anti-Metal RFID Tag is built for metal surfaces where standard tags fail. Designed for long-range performance, harsh environments, and stable data retention, this Anti-Metal RFID Tag is ideal for industrial assets, containers, and equipment tracking using on metal RFID tags.

Learn how to protect data in long-range RFID networks from interception or tampering. Discover Cykeo’s encryption, authentication, and compliance strategies for secure operations.

MoreLearn how to integrate RFID readers with legacy systems without disruptions. Discover Cykeo’s solutions for seamless compatibility and operational efficiency.

MoreDiscover proven methods to eliminate RFID signal interference in high-density environments. Learn how Cykeo’s solutions enhance accuracy for warehouses, hospitals, and logistics hubs.

MoreConfused about what type of antenna RFID tags use? We explain the key designs—coils for proximity and dipoles for long-range UHF tracking—and how to choose.

More