Submit your request to us

We will contact you as soon as possible.

All RFID Product

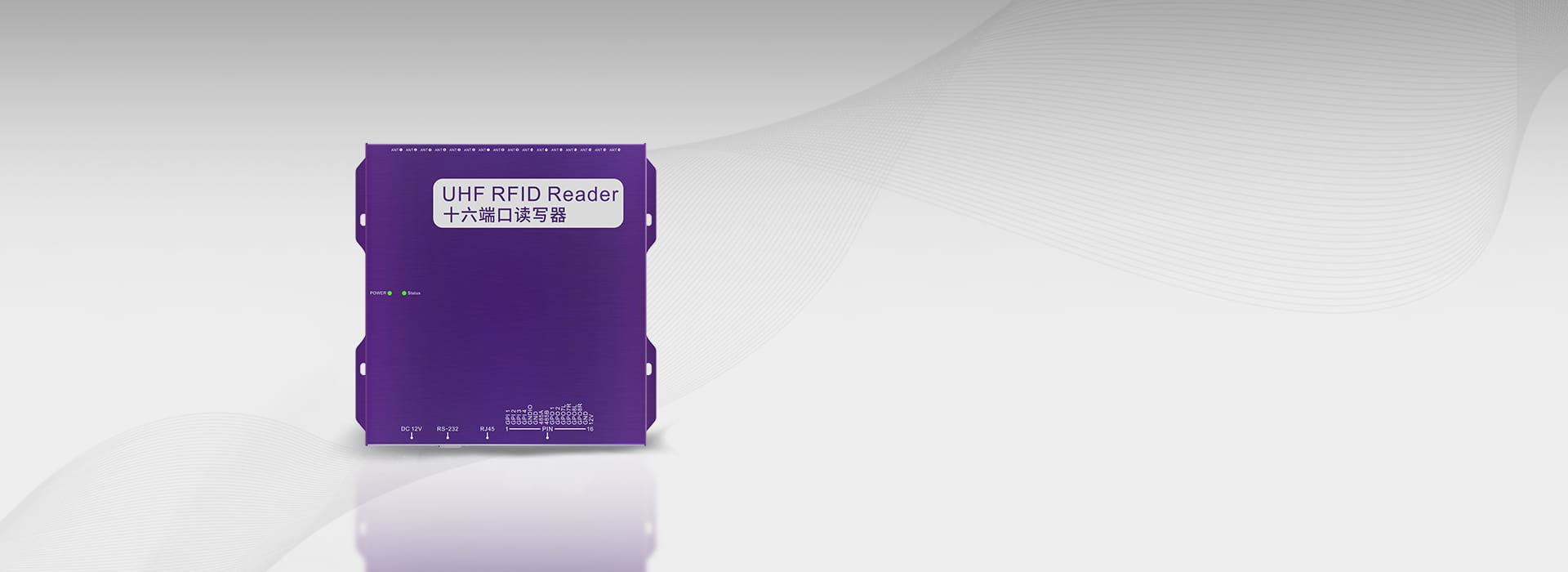

CYKEO-R16L

16-Port Enterprise RFID Reader for Automated Inventory Management

✔️ 16 ports architecture for dense tag environments

✔️ Up to 15 m read distance 400+ tags/per second

✔️ Supports GB/T29768, EPC C1G2, ISO18000-6B/C

The CYKEO CYKEO-R16L RFID Fixed Reader is a 16-port UHF device that’s built for those hectic, high-traffic environments—think busy warehouses, production lines, or even smart lockers. It supports ISO 18000-6C and EPC C1G2 standards, and it can handle over 400 tags per second, so it’s quick enough to keep track of everything—pallets, bins, individual items—without any need for manual scanning.

It’s got an aluminum casing and a fanless design, plus it can handle temperatures from -20°C to 60°C. So, whether you’re dealing with dust, cold storage, or just tough industrial conditions, this reader can take it. It also connects seamlessly to most WMS (Warehouse Management Systems) and MES (Manufacturing Execution Systems), so you can switch to RFID tracking without having to completely revamp your setup.

You’ll find it useful in all sorts of scenarios—like smart parcel lockers for door-by-door tracking, automatic stock counting on shelves, or even real-time identification on production lines. It basically gives teams a clear picture of inventory and material flow with minimal manual effort. Pretty handy for improving efficiency and keeping things moving smoothly.

Main Specifications

Physical Parameters

Developer Support

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

In a warehouse with multiple docks and pathways, a single zone just isn’t enough, so it’s common to treat a multi-port reader (like the CYKEO-R16L) as a set of “micro-zones” that line up with real workflows such as receiving, buffering, picking, packing, and shipping. Different antenna ports cover different spots and can use their own power and filters, so reads don’t get mixed together. Usually, antennas go at dock doors, conveyor bends, and key aisle crossings, and each gets a clear zone name in the system. Then EPC filters, short time windows, and repeated reads help confirm when a tag has actually entered a zone instead of just passing by. Some basic processing—like deduping and generating clean events—happens at the edge, and those events get pushed into the WMS or ERP via API or MQTT to trigger actions like put-away suggestions or shipment confirmations. Once the zones and rules are tuned, people stop thinking about antennas altogether and just rely on the system to show where everything is—misplacements drop, and counting shifts from manual to mostly digital.

RFID Fixed Reader often sits on the same network as servers and control systems, so in sensitive environments, simple passwords just don’t cut it. A practical setup usually covers three areas: first, device access—change defaults, use strong unique passwords, limit who can change RF or firmware, and shut off unused services. Second, network boundaries—put the readers in a segmented VLAN behind a firewall, only allow whitelisted traffic, and use encrypted access for remote configuration, sometimes with a jump server in between. Third, ongoing hygiene—keep firmware current, log access attempts and configuration changes, and send those logs to a central security system. Many critical sites also run basic vulnerability tests before deployment. None of this affects tag reading, but it helps prevent someone from quietly taking control of a device that may sit in the field for 5–10+ years.

Salt air and moisture in ports and coastal cold warehouses can quietly corrode connectors long before the electronics fail, so in these environments people rely on a mix of smarter hardware choices and good maintenance. The reader should have a sealed metal housing and quality connectors, ideally mounted inside a weather-protected cabinet with antenna cables routed downward. Connectors get a protective grease or sealant, and many sites use short pigtails so they can swap a corroded link without replacing the whole reader. In humid or cold-storage spaces, a tiny heater or desiccant inside the enclosure keeps condensation off the board. And every few months, someone just takes a look—checking for corrosion, rust, loose seals, or cracked cables. Treating the reader like site infrastructure instead of a “plug it in and ignore it” device usually stretches its life by many years in salty, wet environments.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.