Submit your request to us

We will contact you as soon as possible.

All RFID Product

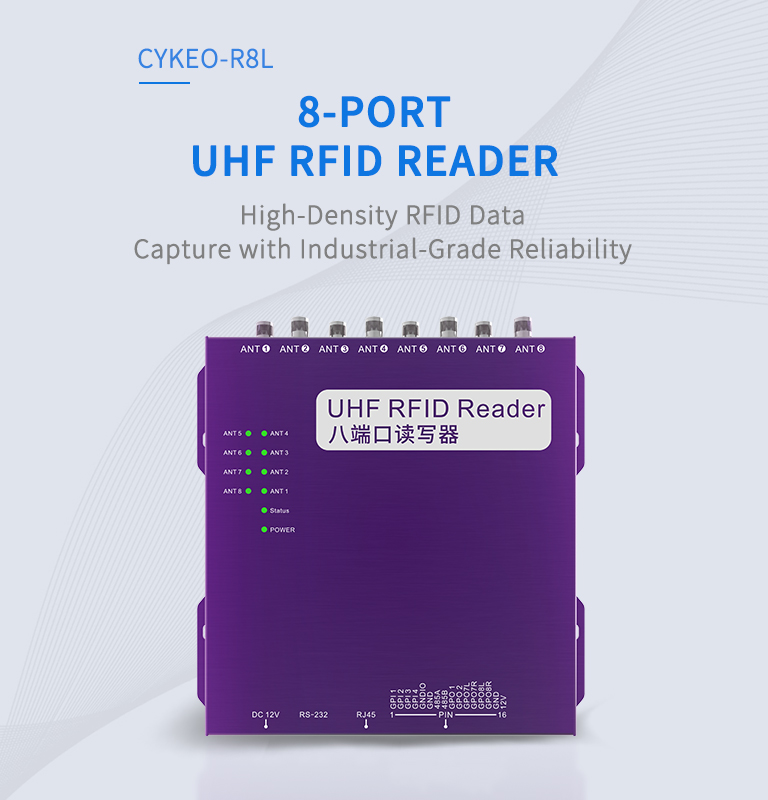

CYKEO-R8L

High-Density RFID Data Capture with Industrial-Grade Reliability

✔️ 8-port Impinj R2000 Fixed RFID Reader

✔️ 600+ tags per second 20m read range

✔️ 4.4 OS and custom API ,Fixed RFID Reader integration

CYKEO CYKEO-R8L UHF Fixed RFID Reader is designed for busy environments where vehicles, assets, or people are constantly moving and barcode scanning just can’t keep up. With the Impinj R2000 platform and 8 antenna ports, one unit can cover multiple lanes or doors, reaching around 20 meters and handling heavy tag traffic smoothly. Inside, it runs Android on a quad-core processor, so integrators can run apps directly on the reader and hook it up to lights, PLCs, and local displays through RS485, GPIO, or HDMI. In real use, it becomes part of the checkpoint: at gates it works with cameras and barriers to confirm IDs before entry; in warehouses it tracks pallets moving in and out; in vaults or controlled rooms it checks valuables automatically; and on production lines it follows items from station to station. The result is fewer manual checks and fewer errors, all running quietly in the background.

Main Specifications

Physical Parameters

Developer Support

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

When a factory thinks long term about automation, it is rarely just about one gate or one conveyor. A good UHF Fixed RFID Reader layout should be able to grow with new lines, extra machines and changed material flows. That is why many integrators treat each line, cell or zone as a small building block instead of building one huge, fragile system.

With CYKEO devices such as the CYKEO-R8L Fixed RFID Reader, a practical approach is to put one or more readers at each key process step, define clear read zones with antennas, and run a small edge application that translates tag reads into simple events: arrived, processed, left, blocked, and so on. These events then move upstream into MES, SCADA or ERP through open interfaces.

A few down-to-earth principles help keep the system future-proof:

Factories that work this way often end up using the same CYKEO Fixed RFID Reader hardware through several waves of upgrades, which is usually cheaper and less disruptive than replacing the infrastructure every few years.

Answer:

Fixed RFID Readers like those from CYKEO can be used in hospitals and labs, but they have to fit around medical workflows and safety rules instead of the other way around. In practice, UHF RFID is already being used to track surgical sets, sample racks, emergency carts and expensive diagnostic equipment, and a properly deployed Fixed RFID Reader rarely draws attention once it is running.

A few points usually come up during planning:

If these basics are followed, a CYKEO Fixed RFID Reader becomes another quiet part of the hospital or lab infrastructure, helping staff know where tools and samples are without changing how they actually treat patients.

In heavy industry, vibration is almost a fact of life. Conveyors start and stop, presses hit with force, and large motors create constant shaking. A Fixed RFID Reader left bolted directly to such structures may still work at first, but connectors and components can suffer over time if no one thinks about maintenance.

For CYKEO Fixed RFID Readers like the CYKEO-R8L

, maintenance in these areas usually comes down to a mix of mechanical care and simple monitoring:

Handled this way, Fixed RFID Readers stop being “mystery boxes” and become just another piece of equipment that the maintenance team understands and can keep running, even when the rest of the plant shakes, vibrates and runs hard most of the day.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.