Submit your request to us

We will contact you as soon as possible.

All RFID Product

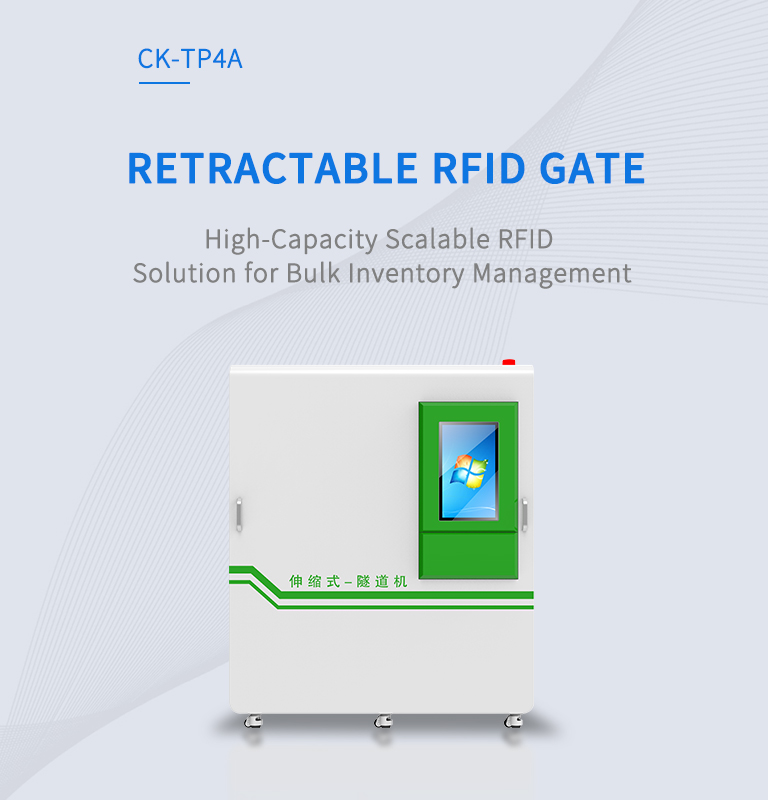

CK-TP4A

A scalable RFID gate built for fast, bulk inventory checks.

✔️ Reads 1000+ tags in one go

✔️ Gate width extends from 1400mm to 2400mm

✔️ 6-antenna array with strong 10dBi gain

The CK-TP4A is a heavy-duty RFID gate for big inventories. It stretches from 1400mm to 2400mm to fit carts and shelves, and its 6-antenna system blasts through 1000+ items in about 10 seconds. The 21.5″ screen shows live data, keeping checks fast and accurate.

Great for big operations—utility meter warehouses, hotel linen centers, or apparel distribution—anywhere you need to scan large batches quickly.

Main Specifications

Physical Parameters

Developer Support

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

The gate stretches from 1400mm to 2400mm, fitting everything from standard carts to big cage trucks. Antennas keep reading performance consistent, and sensors auto-adjust to cover the full width, keeping operations safe no matter the size.

Six antennas cover all angles, so no tags hide. They handle tons of tags at once, cut read time, and back each other up if something blocks the signal—perfect for big carts or stacked shelves.

The system tweaks power on the fly, senses the load shape, and fires antennas in sequence from different angles. Even dense or weirdly shaped piles get all their tags read without misses.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.