Submit your request to us

We will contact you as soon as possible.

All RFID Product

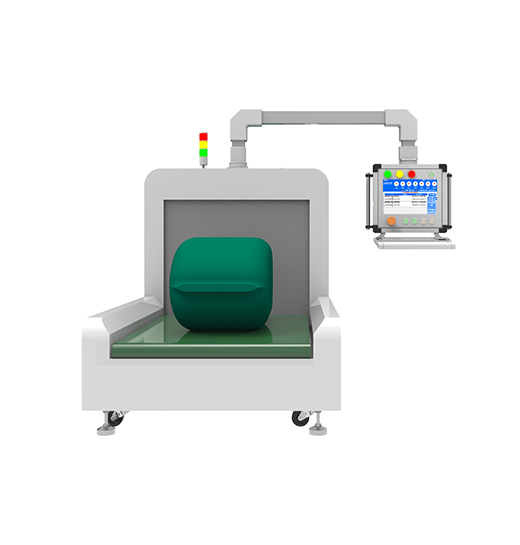

CYKEO-TP3BC

Automated High-Speed RFID Scanning Solution for Smart Warehousing

✔️ 400+ items/sec scanning

✔️ ISO 18000-6C compliant, shielded against interference

✔️ 3-in-1 data check (screen, alarm, software)

A 20m/min conveyor plus RFID tunnel scans batches quickly and cleanly. Motion sensors and shielding keep reads precise, and the 10.1″ touchscreen shows results in real time, cutting almost all manual work.

Perfect for fashion, alcohol, or electronics warehouses needing batch-level tracking during receiving and shipping.

Main Specifications

Physical Parameters

Developer Support

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

It uses four strategically placed RFID readers, dynamic power adjustment, and extra sensors for position and weight. In real warehouses, it cut inventory errors by over 95% while scanning thousands of items per hour.

Yes. Heated antennas, flexible conveyor belts, and IP54 enclosure let it work from -20°C to 60°C. It’s proven in frozen food and pharma storage, keeping read rates near 99% even in tough conditions.

Plug-and-play APIs for SAP, Oracle, and Dynamics 365, plus CSV/XML/JSON exports and edge storage for offline scans. SDKs let you set custom rules, like quarantine or priority routing. Some e-commerce hubs cut reconciliation from hours to minutes with it.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.