Submit your request to us

We will contact you as soon as possible.

All RFID Product

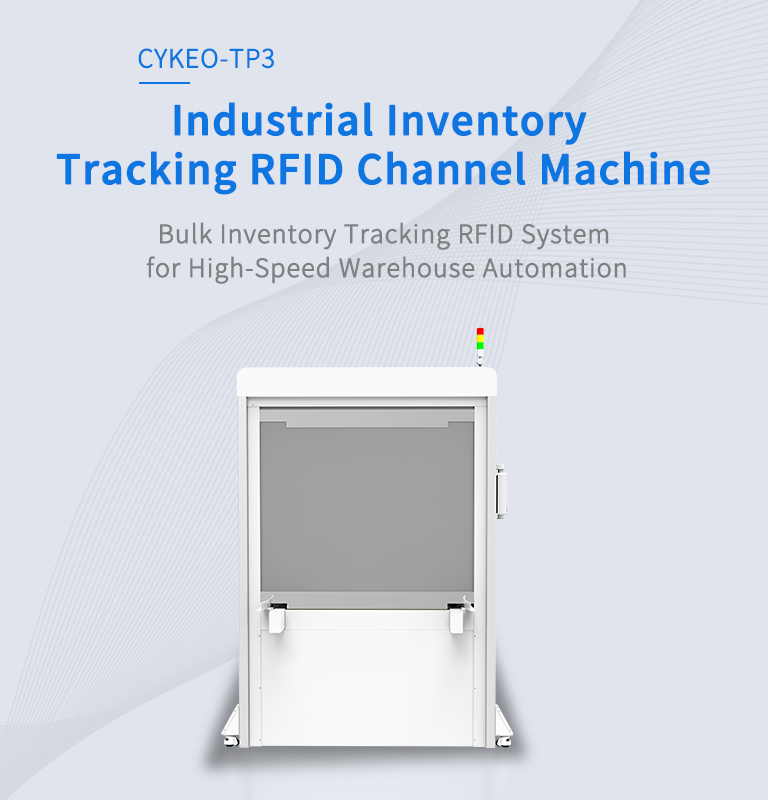

CYKEO-TP3

Bulk Inventory Tracking RFID System for High-Speed Warehouse Automation

✔️ PLC-controlled shutter that keeps signals clean

✔️ Industrial IP65 build with anti-collision design

✔️ 300+ items/min real-time inventory tracking RFID

The CYKEO-TP3 is made for busy warehouses that need fast bulk scans without the usual errors. It handles 300+ tagged items in a few seconds, stays fully ISO18000-6C compliant, and the PLC automation keeps every scan tight and consistent. Most teams end up cutting manual checks and labor time by a huge margin—especially in power meter storage or garment distribution.

Perfect for everyday inventory tracking RFID jobs:

Hotel linen — quick cart-level batch scans

Power utilities — automated meter in/out handling

Apparel logistics — one-shot scanning for 300-piece cartons

Main Specifications

Physical Parameters

Developer Support

* Product performance is based on testing in a controlled environment. Depending on the environment, your results may vary.

Performance Parameters

Operating Environment

NEED A CUSTOM SOLUTION?

Submit your requirements and valid contact details – Our engineers will deliver a custom solution within 24 hours.

The TP3 handles crowded tag situations pretty well. It adjusts its power on the fly, uses IR sensors to focus only on what’s actually inside the tunnel, and double-checks each batch against your list on the touchscreen. Even with stuffed garment cartons, it keeps things clean and avoids the usual missed reads—so you’re not stuck doing manual recounts all day.

Yes—it’s built for rough environments. It runs fine from about –20°C up to hot warehouse conditions, and the internal heater keeps the electronics from fogging up. The frame is tough enough to survive the usual warehouse bumps, and the IP65 sealing keeps dust and rain out. If you’re working below freezing, pairing it with frost-resistant tags makes life easier.

Totally. The system runs on Windows/Android, so you can tweak the workflow however your industry needs. It can log operators and timestamps automatically, switch to low-power modes for sensitive electronics, and export locked, audit-ready reports. A lot of regulated industries use it to cut down on manual paperwork and speed up audits.

Cykeo RFID solutions empower cross-industry operations, delivering precision tracking for supply chain optimization, industrial IoT deployments, and mission-critical asset management across logistics, healthcare, aviation, smart manufacturing, energy infrastructure, and security systems.